Two-stage separation method for disposing building garbage

A construction waste and stage separation technology, which is applied in the direction of solid separation, chemical instruments and methods, and separation of solids from solids with airflow, can solve the problems of affecting the quality of recycled aggregate, high moisture content of aggregate, and poor separation effect and other problems, to achieve the effect of high screening efficiency, reduced water content and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiments. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

[0025] The two-stage separation method of construction waste disposal of the present invention comprises the following steps:

[0026] (1) Screening: Use a screening device to classify recycled materials to obtain coarse and fine aggregates, among which recycled aggregates refer to construction waste after coarse and medium crushing.

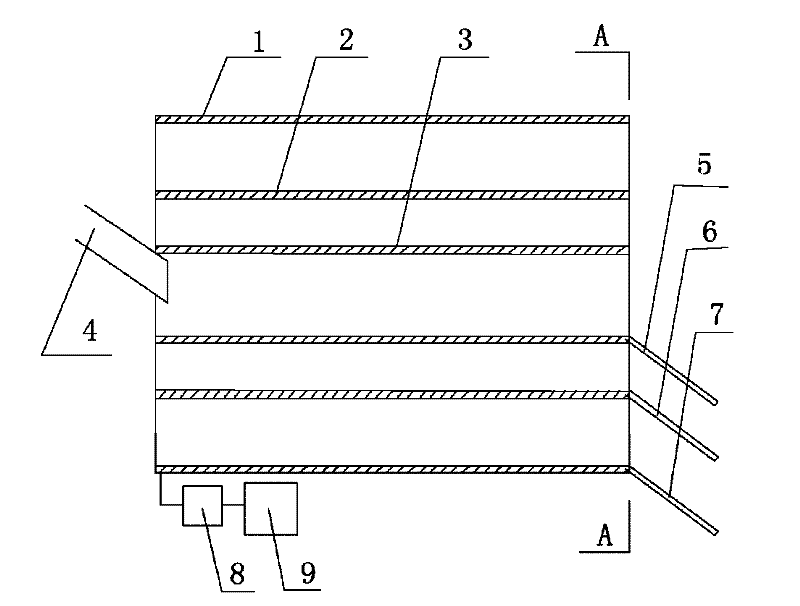

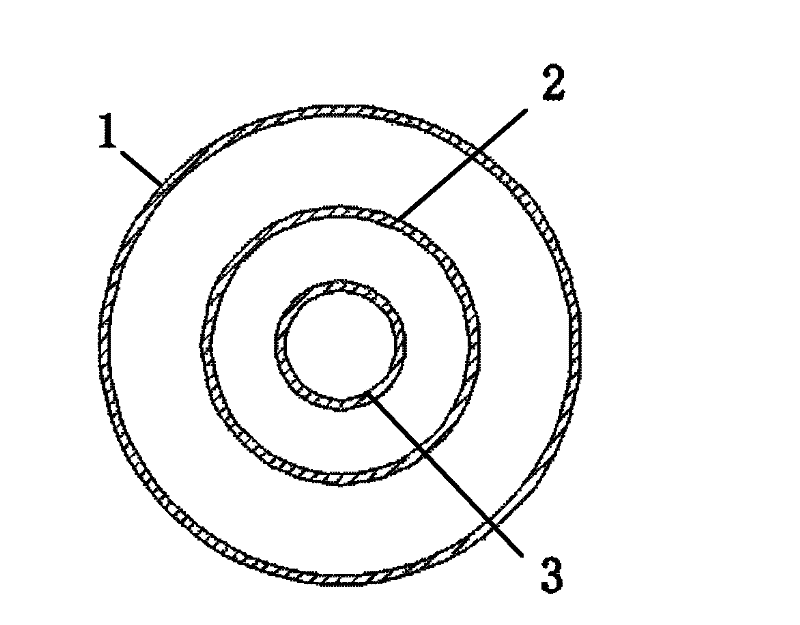

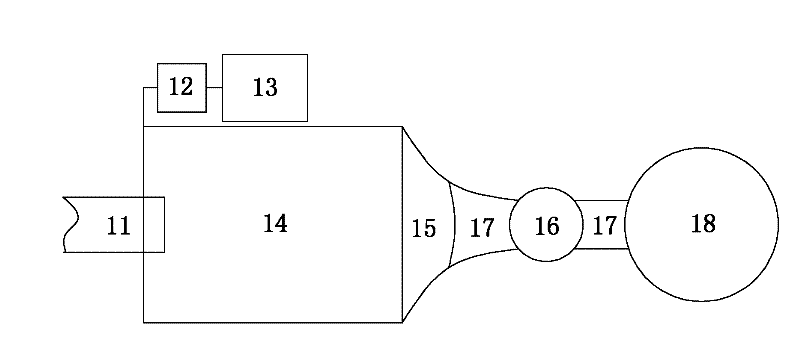

[0027] In a preferred embodiment of the present invention, a drum-type cylindrical screen is used as a screening device, with 1 to 3 layers of screen cylinders, the main function is to separate the recycled coarse and fine aggregates and to separate part of the light combustibles into the coarse aggregates, Make it possible to separate light combustibles in the next step. Such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com