Helical blade drawing device

A technology of spiral blades and blades, which is applied in the field of conveying machinery manufacturing, can solve problems such as high cost, low equipment utilization rate, and large investment, and achieve the effects of convenient use, reduced labor intensity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The accompanying drawing discloses a non-restrictive structural schematic diagram of a preferred embodiment involved in the present invention, and the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

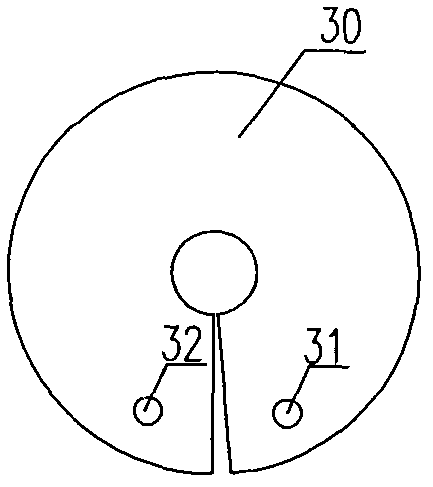

[0018] Such as image 3 As shown, a fixing process hole 31 and a stretching process hole 32 are drilled on the helical blade blank 30 to be drawn.

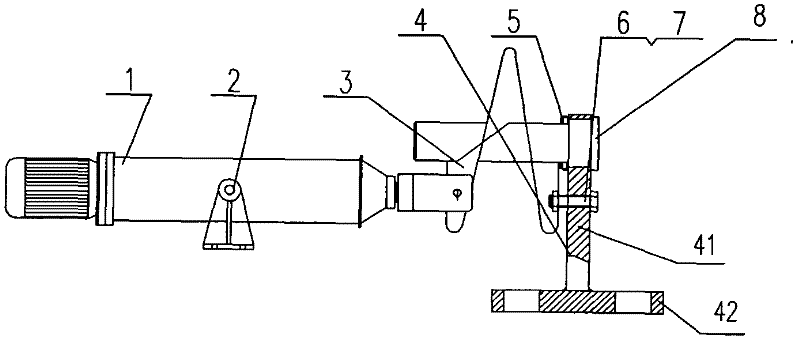

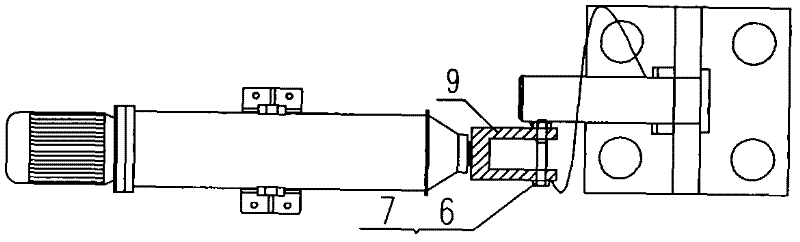

[0019] Such as figure 1 and figure 2 As shown, a spiral blade drawing device according to the present invention includes a frame and a mandrel. The frame 4 includes a bottom plate 42 and a support plate 41 fixedly connected to the bottom plate. The mandrel 8 is vertically installed on the support plate 41, the pulling braking power device is located on the same side of the mandrel 8, the extending end of the pulling braking power device is provided with a blade stretching installation part, and the side of the support plate 41 located at the lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com