Automatic welding and cutting device for modified cross-section bellows

A technology of automatic welding and cutting device, applied in welding/cutting auxiliary equipment, auxiliary device, measuring device, etc., can solve the problems of high installation cost, unstable welding quality, large error, etc. Welding process requirements and the effect of sophisticated mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

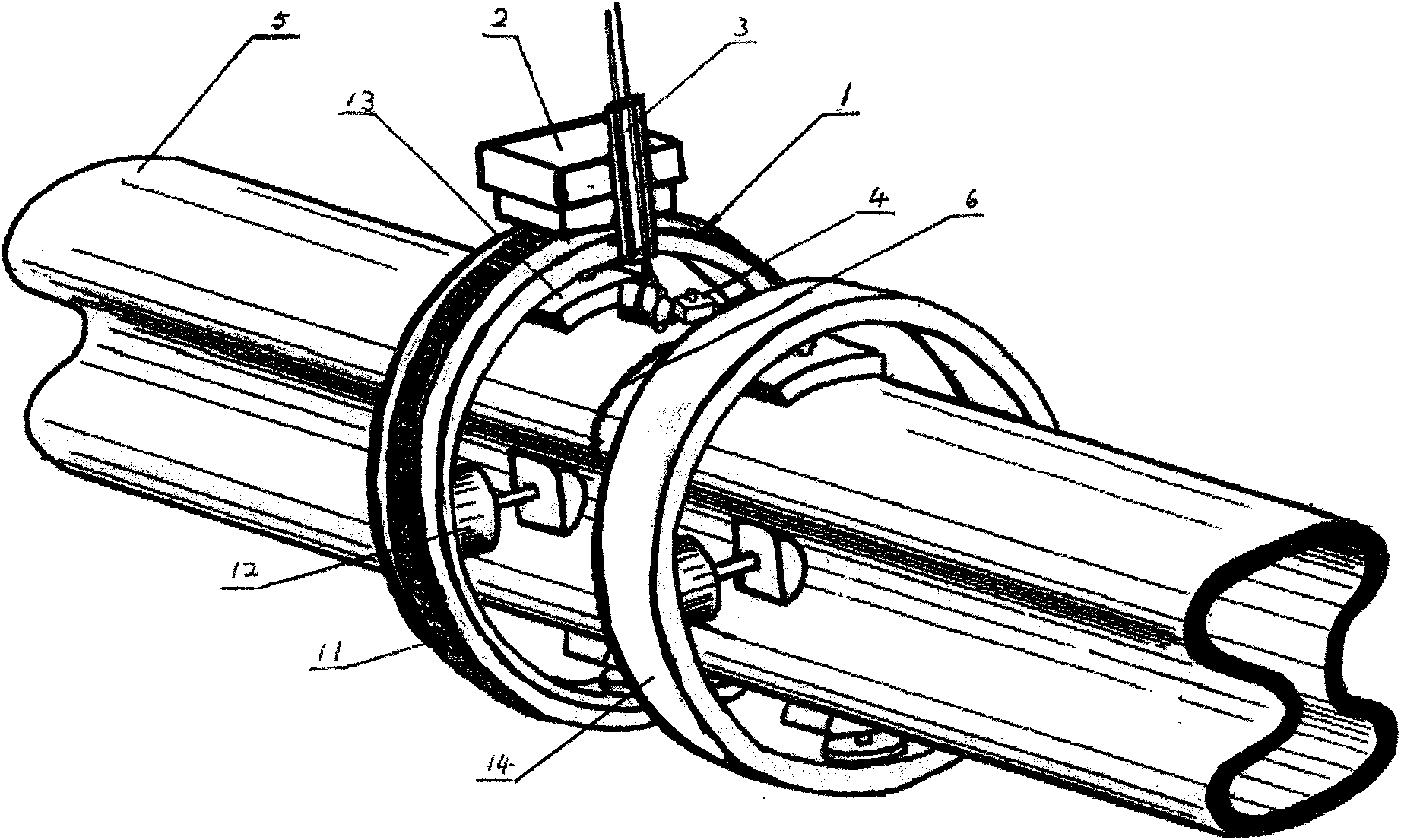

[0016] The main structure of the clamping ring guide rail 1 of the present invention adopts the "quick disassembly and assembly rail for pipeline all-position automatic welding", patent number: ZL200920105416.4; the two-way locking welding / cutting carriage 2 adopts the "welding carriage with two-way locking mechanism" ", Patent No.: ZL200920105419.8.

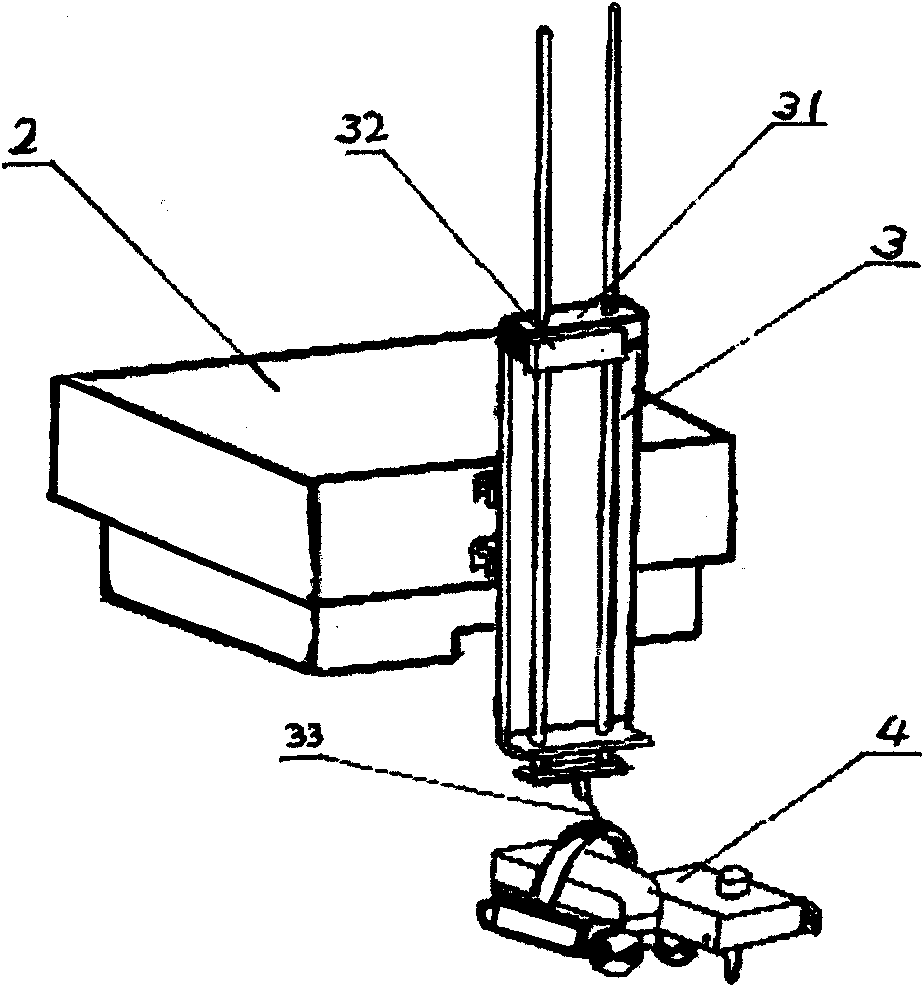

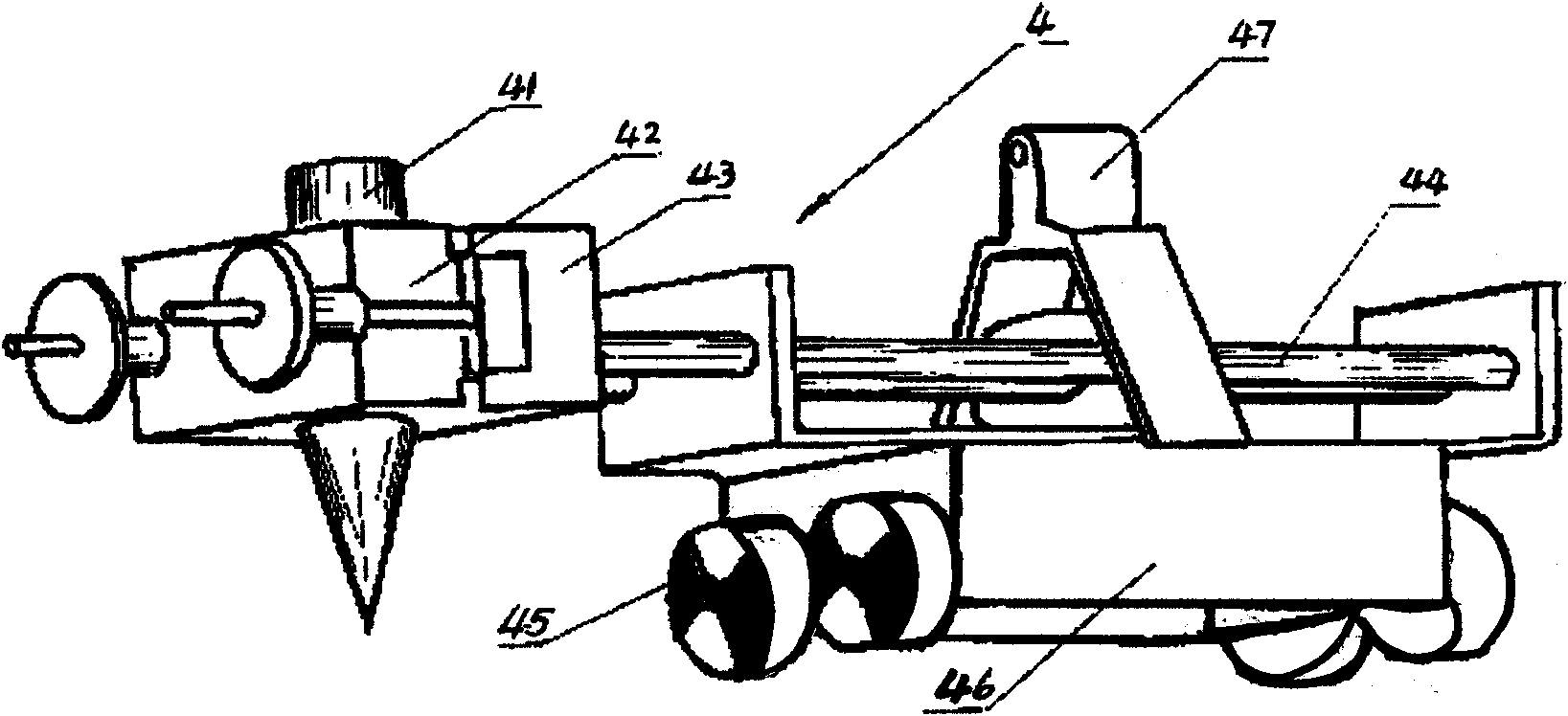

[0017] by figure 1 , figure 2 with image 3 Shown, an automatic welding and cutting device for corrugated pipes with special-shaped cross-sections is mainly composed of clamping ring guide 1, two-way locking welding / cutting trolley 2, height tracking device 3 and bellows contour detecting and tracking device 4. The hydraulic mechanism 12 is installed on the quick disassembly and assembly guide rail 11 for position automatic welding. The concave shaping block 13 and the convex shaping block 14 form the clamping ring guide 1, and the welding / cutting trolley 2 is equipped with a two-way locking mechanism to make it bidirectional The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com