Multi-shaft precise linkage feeding equipment

A linkage and precise technology, applied in the direction of metal processing equipment, metal processing machinery parts, feeding devices, etc., can solve the problems of low precision, low precision of multi-axis feed displacement, difficult to control, etc., to ensure monitoring and compensation, The effect of solving the low accuracy of multi-axis feed displacement and improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

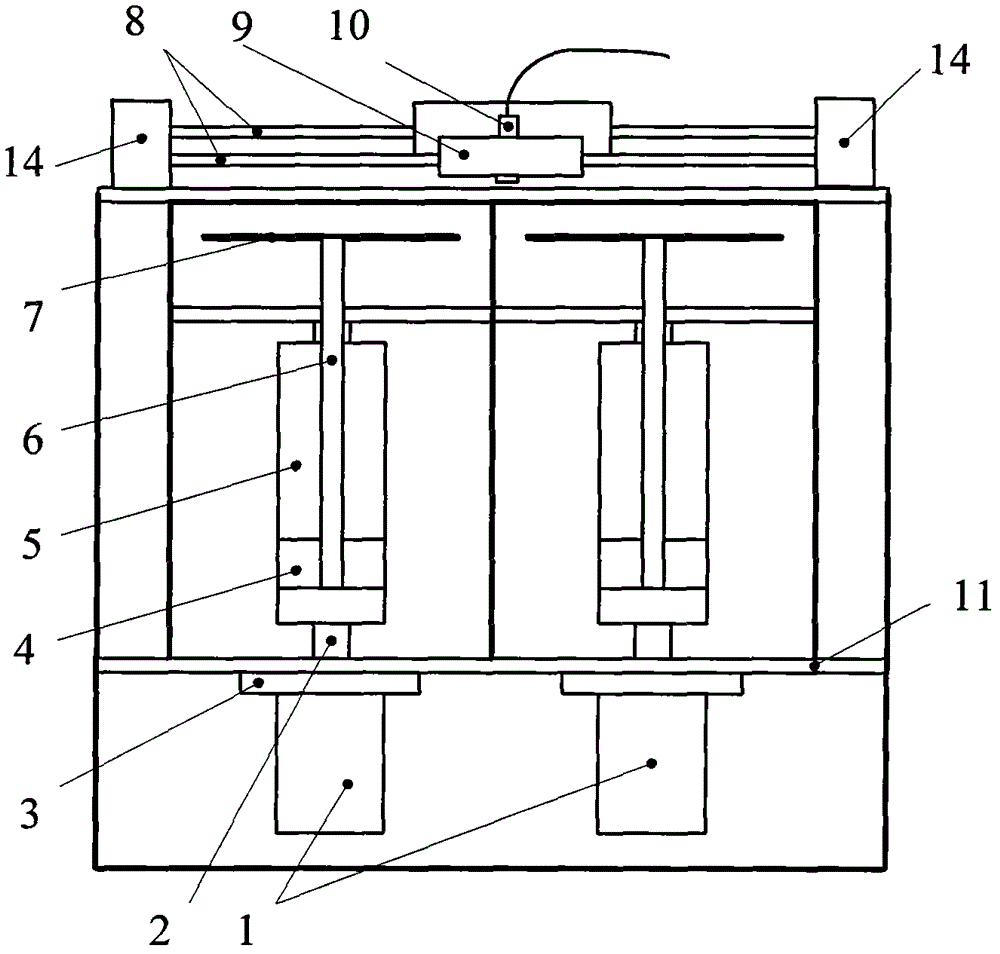

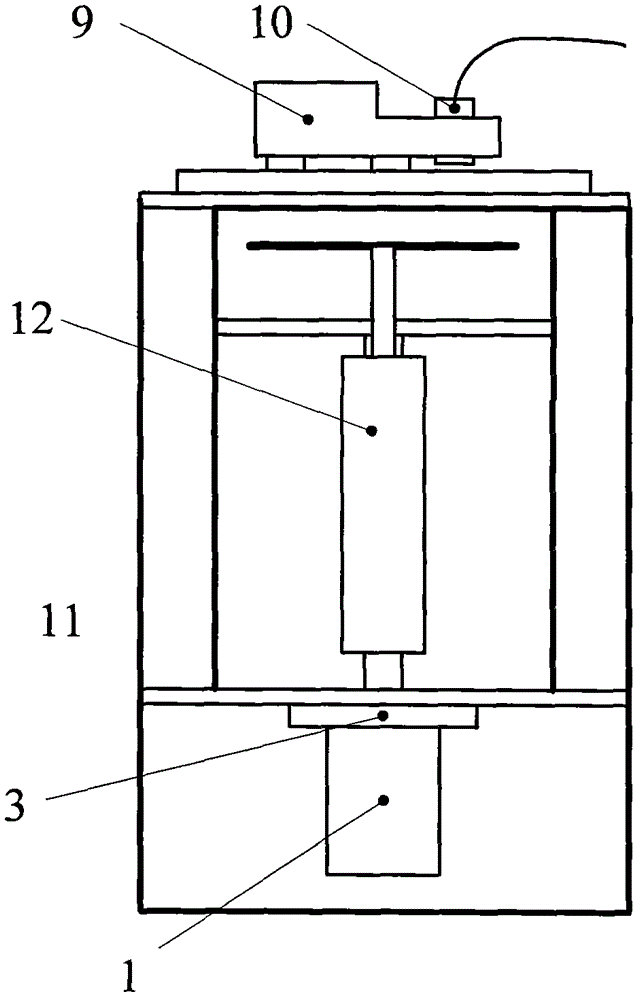

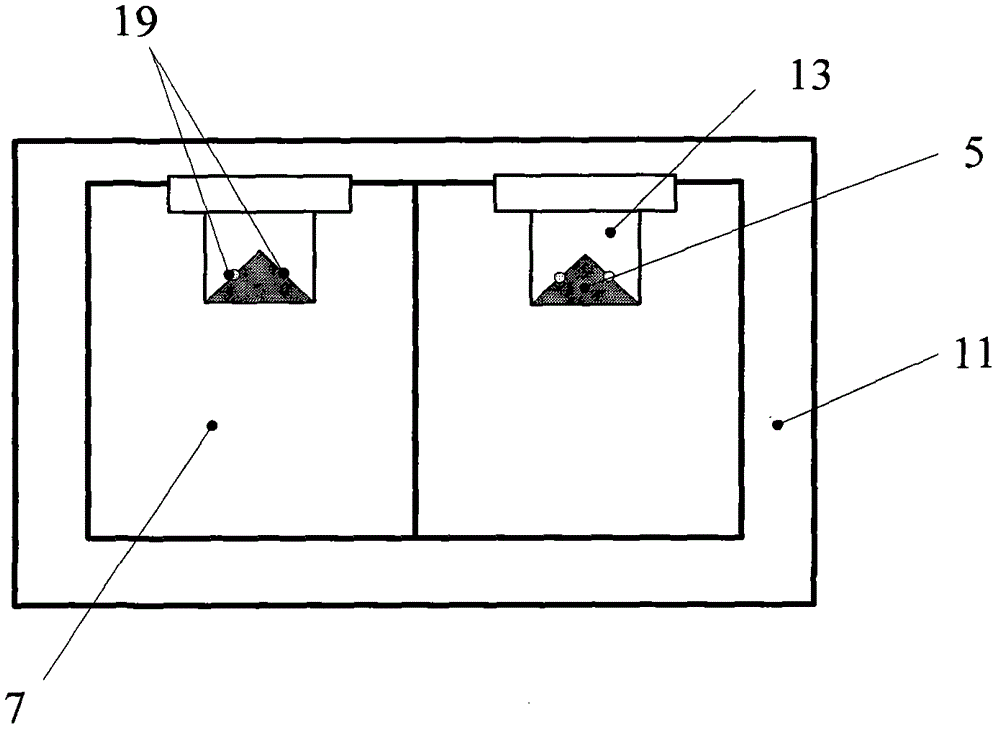

[0015] The equipment includes servo motors (1, 15, 17), a controller, a precision screw 2 and a sliding table guide rail (4, 5, 6) composed of a liftable working platform, and a gantry-type X-Y working platform (8, 9, 14) 1. The fixed bracket 11, the equipment includes the linkage control of more than five axes, all the control axes are connected with the servo motors, and coordinate actions through the multi-axis controller. The lifting work platform 7 is connected to the slide table and fixed on the guide rail to run along the Z direction. The guide rail is a V-shaped linear guide rail 5; the grating scale 12 is installed on the outer wall of the slide table; the servo motor 1 is directly connected to the precision screw 2 through the rigid coupling 3; The gantry type X-Y working platform is positioned directly above the lifting platform; the movement in the X-Y direction is connected with the synchronous pulley (16, 18) and the servo motor (15, 17); the X-Y working platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com