Curing-agent-free treatment-free silk-screen printing ink for thermoplastic polyurethane material

A screen printing ink, treatment-free technology, applied in the field of ink, can solve the problems of bad hand feeling, waste of resources, pollution of the environment, etc., and achieve the effects of excellent adhesion, good leveling, and excellent use performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069]41 parts (weight) of PU resin, 31 parts (weight) of ketone solvent, 26.8 parts (weight) of ester solvent, 1.2 parts (weight) of additives, mix well, stir at high speed until completely dissolved, and then filter through 200 mesh gauze Get the finished product.

Embodiment 2

[0071] 45 parts (weight) of PU resin, 26.5 parts (weight) of ketone solvent, 12 parts (weight) of ester solvent, 1 part (weight) of defoamer, mix well and stir evenly at high speed, then add 0.5 part (weight) of dispersant ), 15 parts of titanium dioxide.

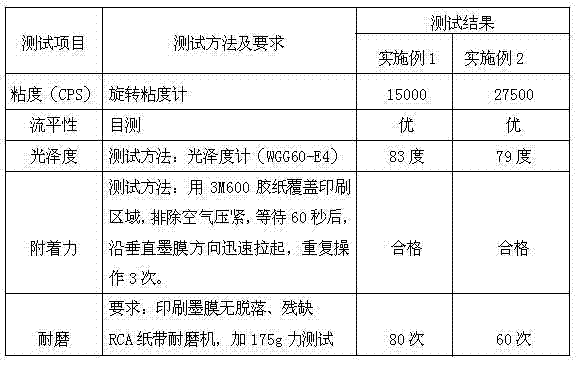

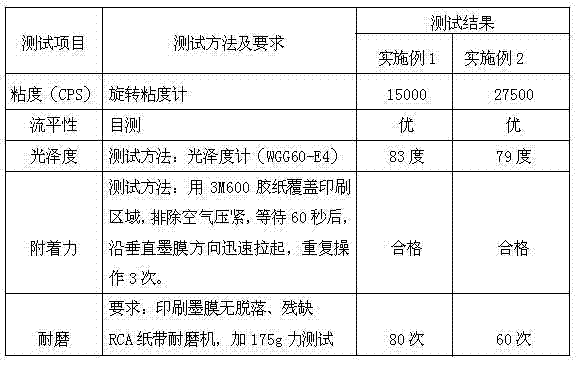

[0072] The TPU material obtained in the above examples does not add curing agent, and the printing effect and physical and chemical index status of the screen printing ink on the material are shown in figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com