Foundation pit side wall prestressed anchor rod spreader beam row pile enclosing structure

An enclosure structure and prestressing technology, which is applied in the direction of foundation structure engineering, excavation, construction, etc., can solve the problems of large amount of enclosure pile materials, inability to realize flexible layout, and easy quality problems, so as to shorten the construction period and ensure the enclosure The effect of maintaining quality and reducing the amount of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

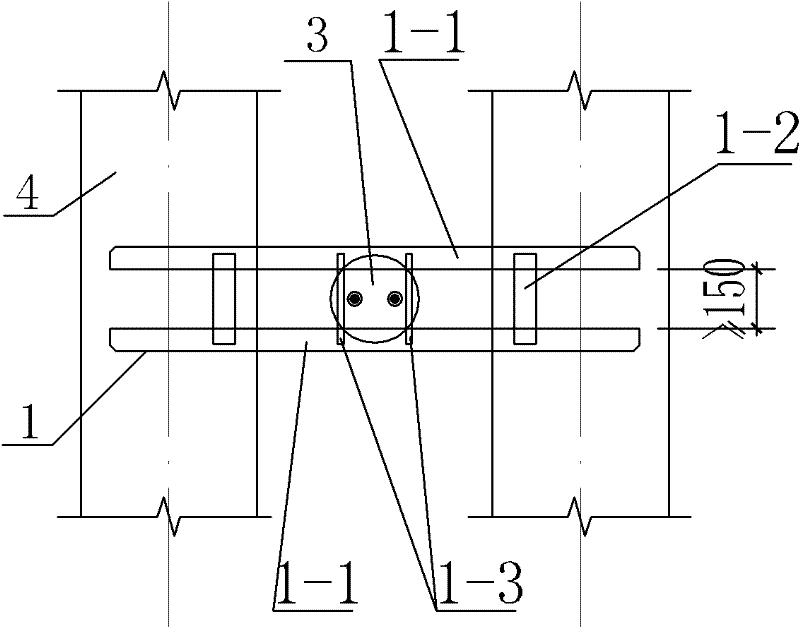

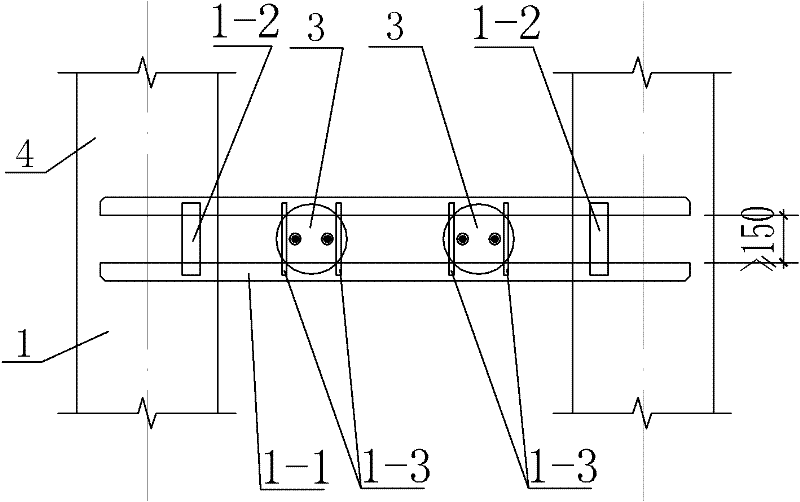

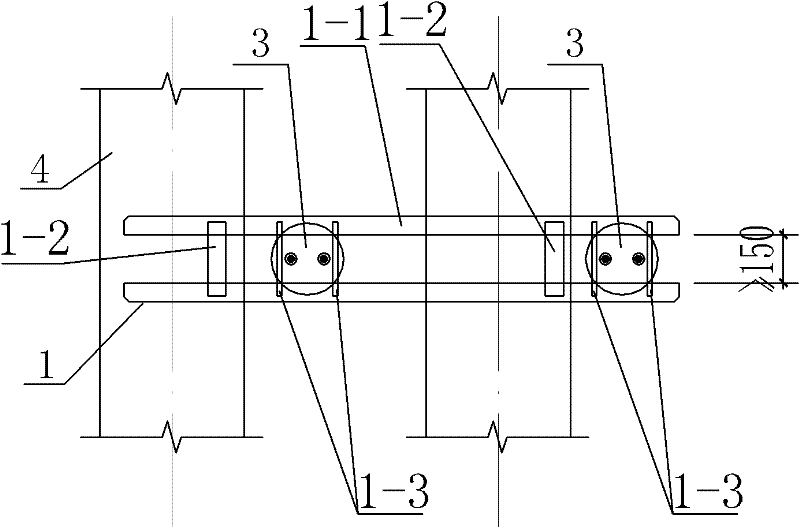

[0010] Specific implementation mode one: as Figure 1-7 As shown, the foundation pit side wall prestressed anchor beam beam pile enclosure structure described in this embodiment includes a plurality of anchor connectors and a plurality of segmented beams 1, and each segmented beam 1 passes through At least one anchor connecting piece firmly abuts (supports) on two adjacent rows of piles 4, and the plurality of segmented beams 1 are arranged from top to bottom along the pile height direction.

specific Embodiment approach 2

[0011] Specific implementation mode two: as Figure 1-7 As shown, the segmented load beam 1 in this embodiment is a profiled steel load beam, and each segmented load beam 1 includes two channel steels 1-1, at least two decorative plates 1-2 and at least one pair of wedge-shaped steel plates 1-3, two channel steels 1-1 are arranged parallel to each other and welded together by at least two patch plates 1-2 arranged in a dispersed manner, and at least one pair of wedge-shaped steel plates 1-3 are welded on two grooves arranged in parallel and opposite The outer side of Steel 1-1. The thickness of the wedge-shaped steel plate 1-3 can be 10mm-20mm. A pair of wedge-shaped steel plates 1-3 are double-sidedly welded to the section steel beam. Other components and connections are the same as those in the first embodiment.

[0012] The beam section of the segmented beam described in this embodiment is connected by two channel steels to form an I-shaped steel, and the commonly used s...

specific Embodiment approach 3

[0013] Specific implementation mode three: as Figure 1-7 As shown, each anchor connector in this embodiment includes a prestressed anchor 2 and an anchor 3, the anchor end of the prestressed anchor 2 is fixed in the soil body of the side wall of the foundation pit, and the prestressed steel of the prestressed anchor 2 The beam 2-1 passes through the gap between two adjacent rows of piles 4 and the segmented load beam 1 is tightened by the anchor 3, and a pair of wedge-shaped Steel plate 1-3. The edge of the channel steel is strictly forbidden to be strung, that is, there is a certain gap between the prestressed steel beam 2-1 and the edge of the channel steel. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com