Performance testing equipment for humidifying function material and testing method

A technology for functional materials and testing equipment, applied in the direction of removing certain components and weighing, using substances to absorb and weighing, etc., can solve the problem of affecting the stability of the test environment, the air flow on the surface of the test sample has a great influence on the test results, and the speed cannot be Control and other issues to achieve the effect of reducing impact, good stability, and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

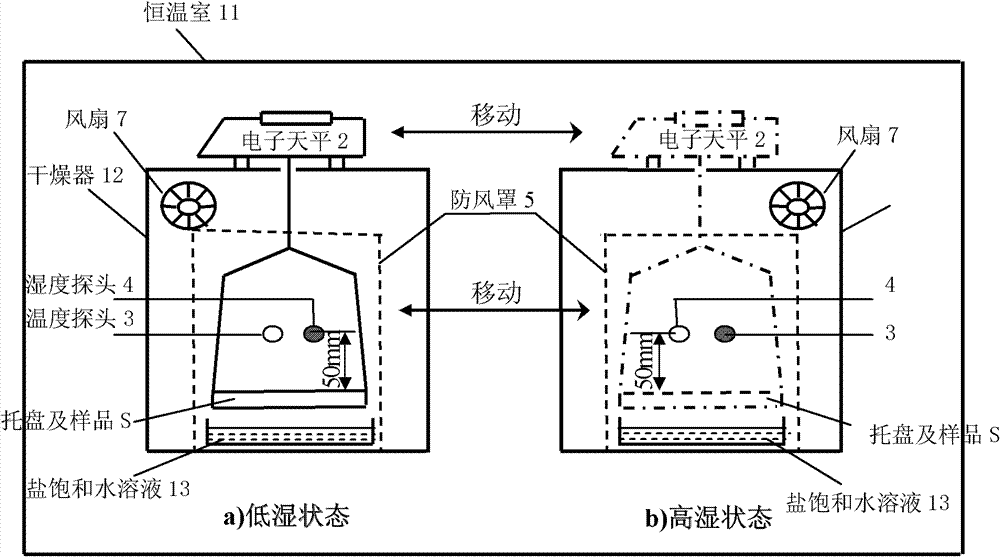

[0034] The invention is made for the establishment of industry standards for humidity-regulating building materials. It mainly provides a reasonable, scientific and stable performance test system for humidity control materials, which is used to test the moisture absorption and desorption performance of materials by the humidity reaction method.

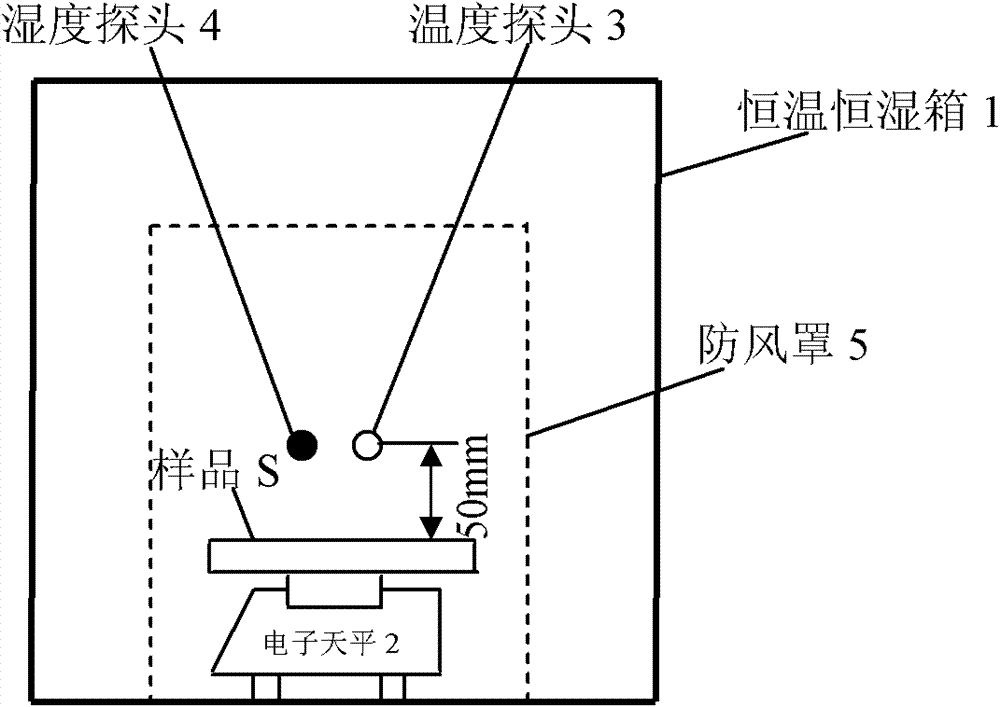

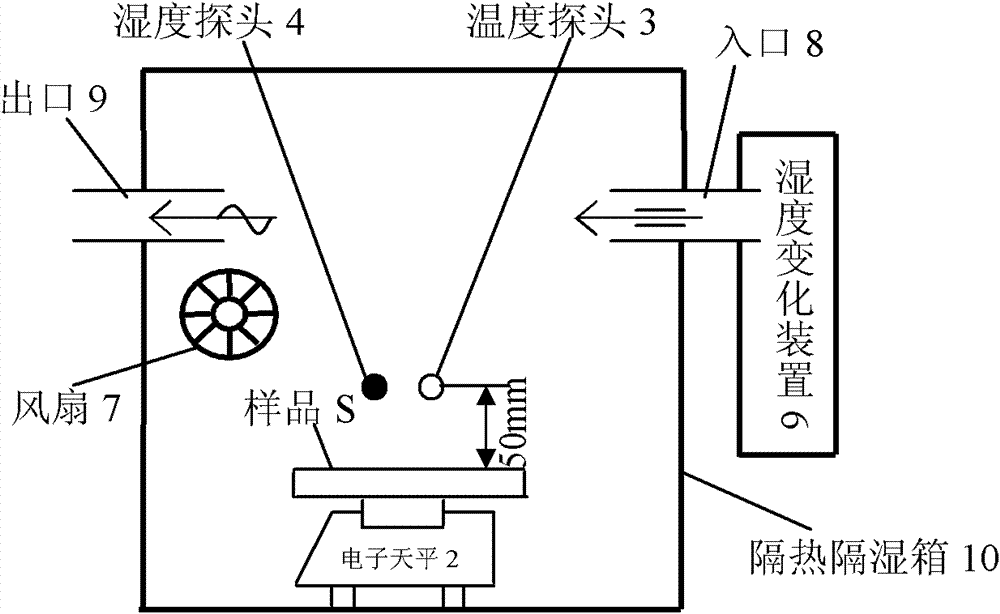

[0035] The humidity-conditioning material testing device of the present invention is mainly composed of a relative humidity control part, a weighing part and a temperature and humidity monitoring part. The relative humidity control part is used to manufacture and maintain the test environment of the test sample; the weighing part is an electronic balance, which is used to accurately weigh the test sample in real time; the temperature and humidity monitoring part includes a temperature probe and a humidity probe, which extend into the relative humidity control part The device is located above the surface of the test sample to monitor t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com