Machine vision detection method and system for detection of various products

A machine vision inspection and visual inspection technology, applied in the direction of optical testing flaws/defects, etc., can solve problems such as inability to work for a long time, high error rate, product visual inspection error, etc., and achieve full flexibility without manual operation. Effect

Inactive Publication Date: 2011-11-23

蒋泽淑

View PDF5 Cites 29 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the quality inspection of the appearance and shape of known batch products is mostly carried out by human eyes, because the judgment of human eyes is not easy to quantify and execute, human eyes are prone to fatigue, people are prone to emotions, and some high-temperature or toxic environments cannot Factors such as long hours of work have resulted in the general misjudgment and high misjudgment rate of current product visual inspections.

[0003] As a result, machine vision inspection technology has been rapidly developed and popularized. However, the existing machine vision inspection technology has a single function, and a machine vision inspection device can generally only detect a single specific product. Visual inspection of multiple components of a complete product requires a variety of visual inspection machines, which not only wastes resources, but also reduces the overall inspection efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

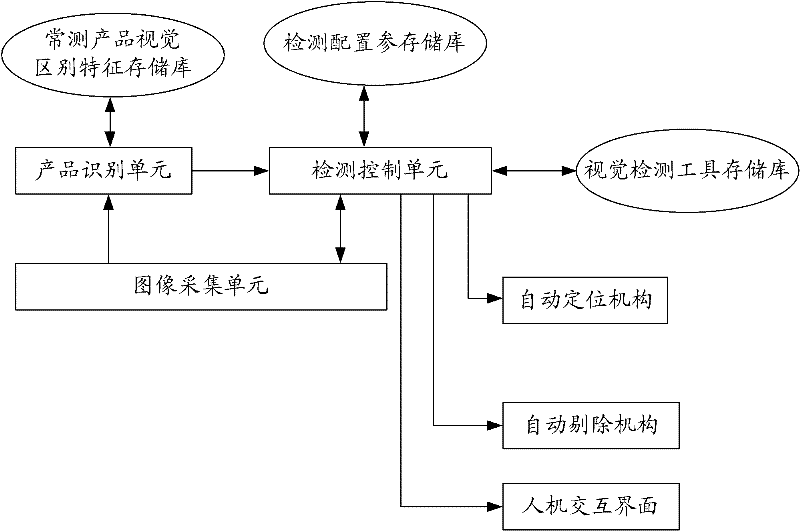

[0033] Such as figure 1 As shown, the machine vision inspection system that can be used for a variety of product inspections, including:

[0034] Commonly tested product visual distinguishing feature repository, used to pre-store the visual distinguishing features of various frequently tested products;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

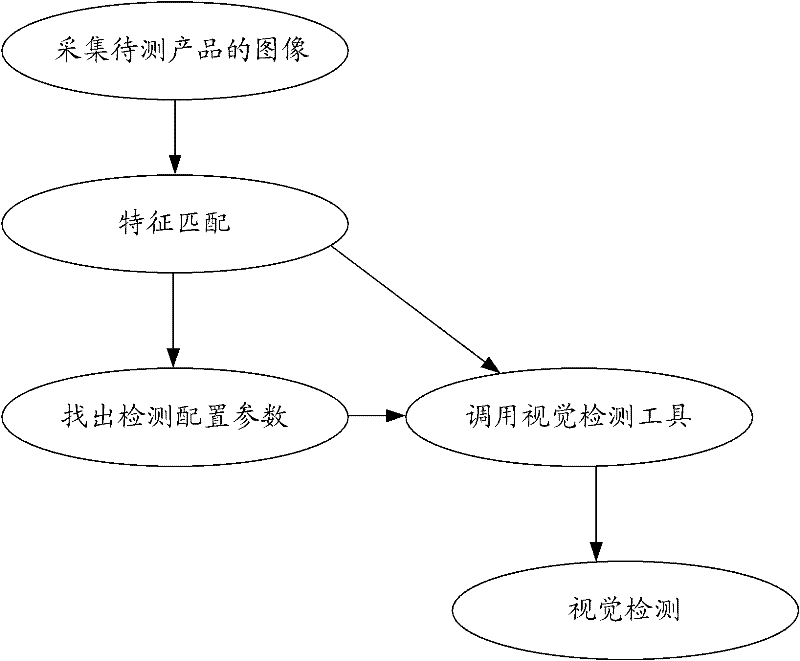

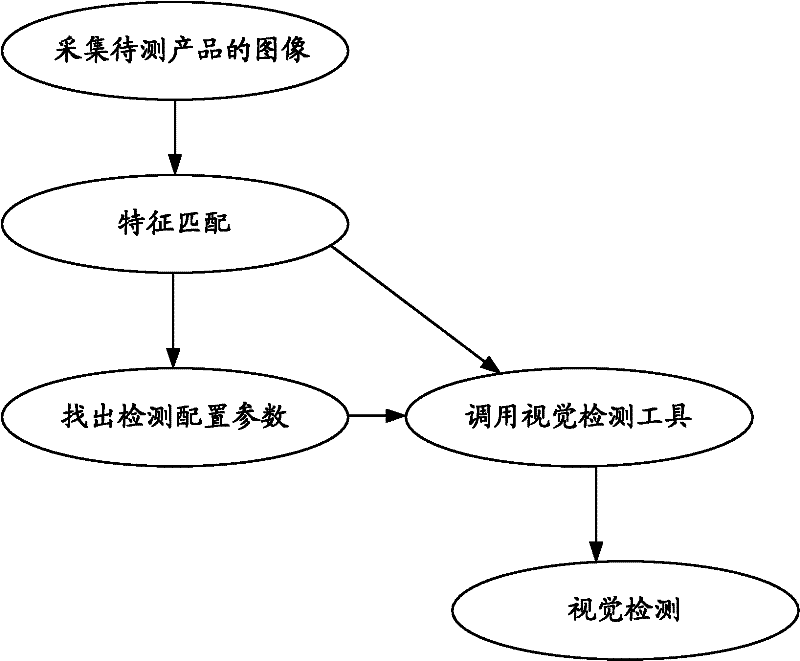

The invention discloses a machine vision detection method and a machine vision detection system for the detection of various products. The method comprises the following steps of: acquiring images of the products to be detected, performing feature matching of the images and prestored vision distinguishing features to find normally-measured products matched with the images, so that a machine considers that the products to be detected and the found normally-measured products are the congeneric products obviously; finding detection configuration parameters corresponding to the normally-measured products; and calling vision detection tools corresponding to the normally-measured products, loading the found detection configuration parameters, and performing vision detection on the products to be detected according to the called vision detection tools. When the machine vision detection method and the machine vision detection system are used, the models of the products can be identified automatically and intelligently, and after being identified, the products can be detected.

Description

technical field [0001] The invention relates to the technical field of automatic production, in particular to a machine vision detection method and system that can be used for various product detection. Background technique [0002] At present, the quality inspection of the appearance and shape of known batch products is mostly carried out by human eyes, because the judgment of human eyes is not easy to quantify and execute, human eyes are prone to fatigue, people are prone to emotions, and some high-temperature or toxic environments cannot Factors such as long hours of work have resulted in the general misjudgment and high misjudgment rate of current product visual inspections. [0003] As a result, machine vision inspection technology has been rapidly developed and popularized. However, the existing machine vision inspection technology has a single function. Generally, a machine vision inspection device can only be used to detect a single specific product. Visual inspecti...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N21/88G01N21/89

Inventor 蒋泽淑

Owner 蒋泽淑

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com