Method and system for supervising clothing production based on radio frequency identification (RFID) technology

An RFID tag and clothing technology, applied in the field of clothing production, can solve the problems of affecting production efficiency, unable to understand the progress of order production in real time, and low accuracy, and achieve ingenious design, improve production efficiency and decision-making management capabilities, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

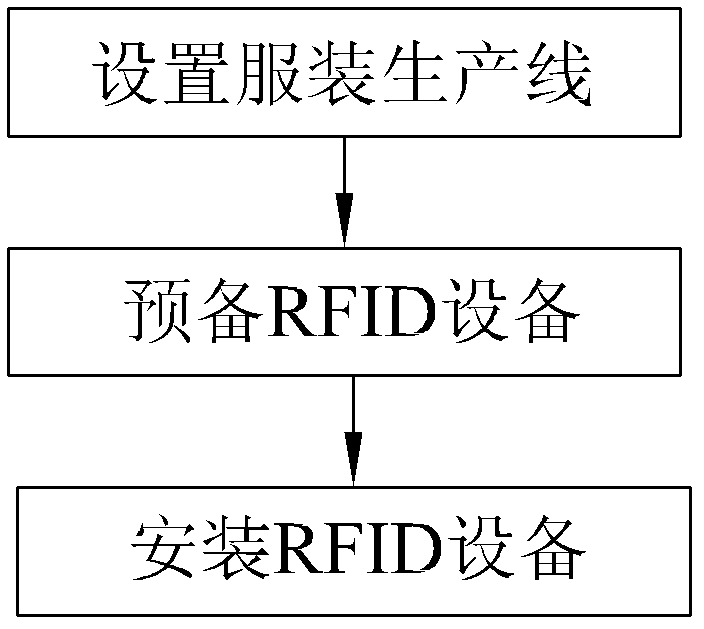

[0031] Example: see figure 1 and figure 2 , a kind of method for supervising garment production based on RFID technology provided by the present embodiment, which includes the following steps:

[0032] (1) Set up the garment production line, formulate the corresponding production process according to the garments to be produced, and then set the corresponding number of stations according to the process, and arrange these stations in sequence according to the production line of the production process to form a garment production line ;

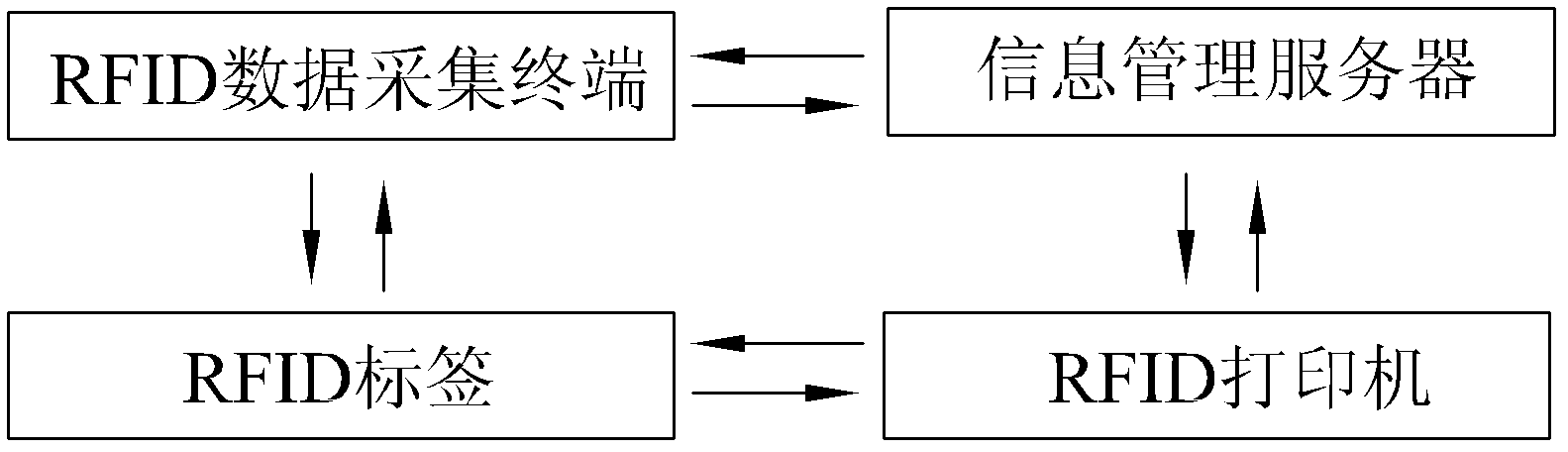

[0033] (2) Prepare RFID equipment, prepare a number of RFID data collection terminals and an information management server capable of processing the RFID data information collected by the RFID data collection terminals;

[0034] (3) Install RFID equipment, corresponding to installing an RFID data collection terminal on each station, the RFID data collection terminal is used to record the operation information of the corresponding station, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com