Surface treatment method of mirror stainless steel objects

A technology for mirror stainless steel and treatment methods, which is applied in the field of polishing and crystallization, and can solve problems such as sand marks, emery cloth marks and throw marks, high-temperature deformation of mirror stainless steel objects, sags, and brightness, etc., so as to improve the appearance and avoid over-polishing deformation sunken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

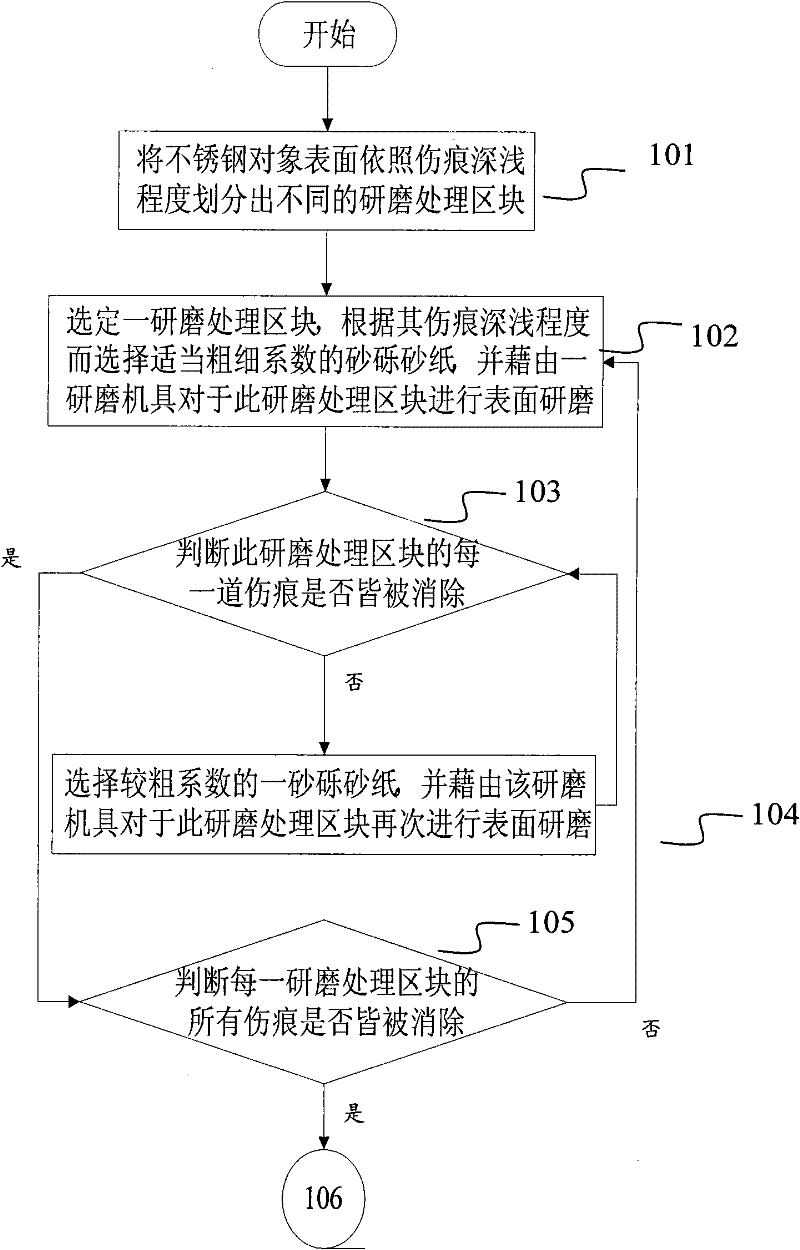

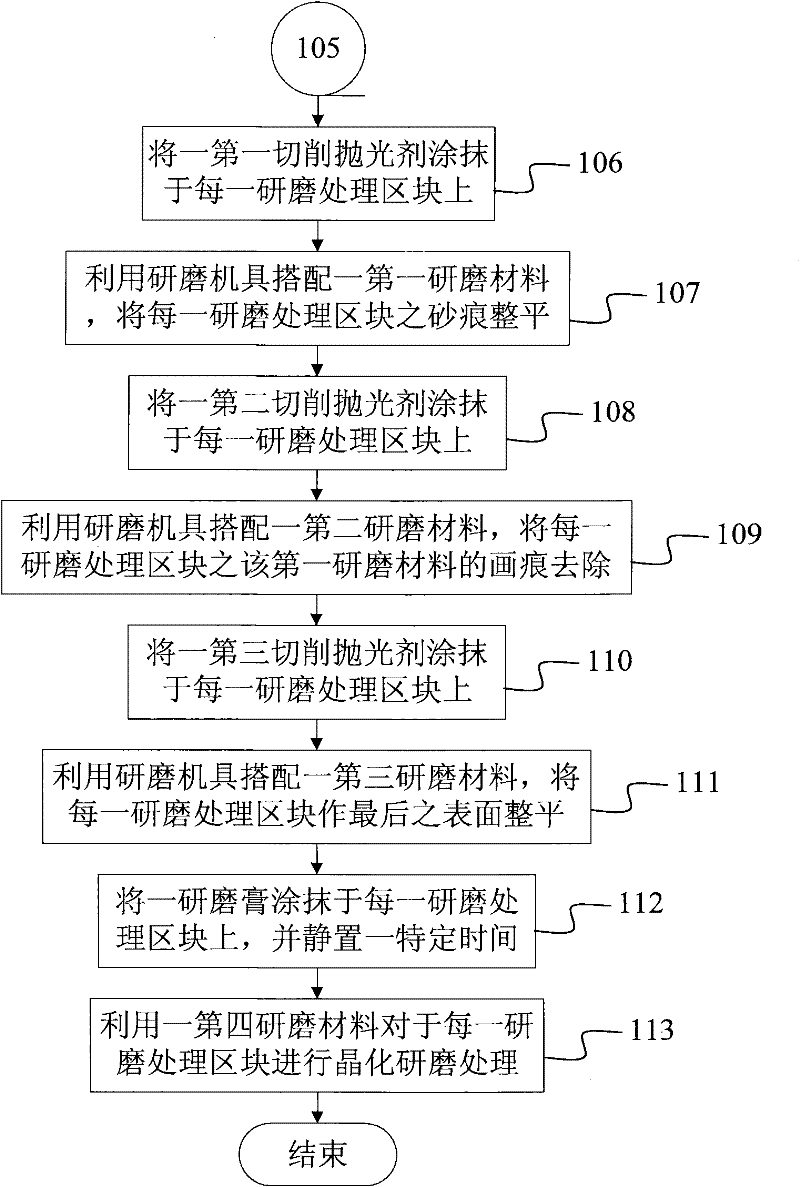

[0042] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

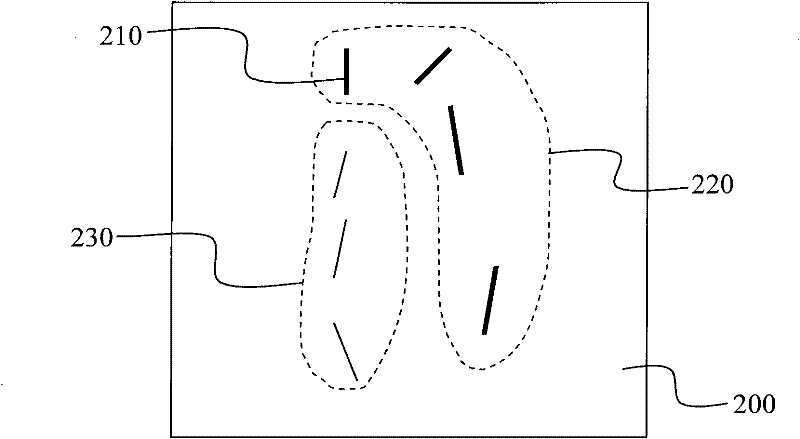

[0043] Figure 1A and Figure 1B It is a flow chart of the treatment method for the surface of a mirror-finished stainless steel object according to the first preferred embodiment of the present invention, which includes the following steps: dividing the surface of the stainless steel object into different grinding treatment blocks according to the depth of the scar (step 101), and performing step 102 Select a grinding treatment block, select the grit sandpaper with appropriate thickness coefficient according to the depth of its scars, and use a grinding machine tool to carry out surface grinding (step 102) on this grinding treatment block, and perform step 103; judge this grinding treatment Whether each scar of the block is all eliminated (step 103), if so, then proceed to step 105, if not, then proceed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com