High-temperature forming system for quartz crucible

A high-temperature forming, quartz crucible technology, used in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of large volume, inability to manufacture thick walls, long service life, etc. heat loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

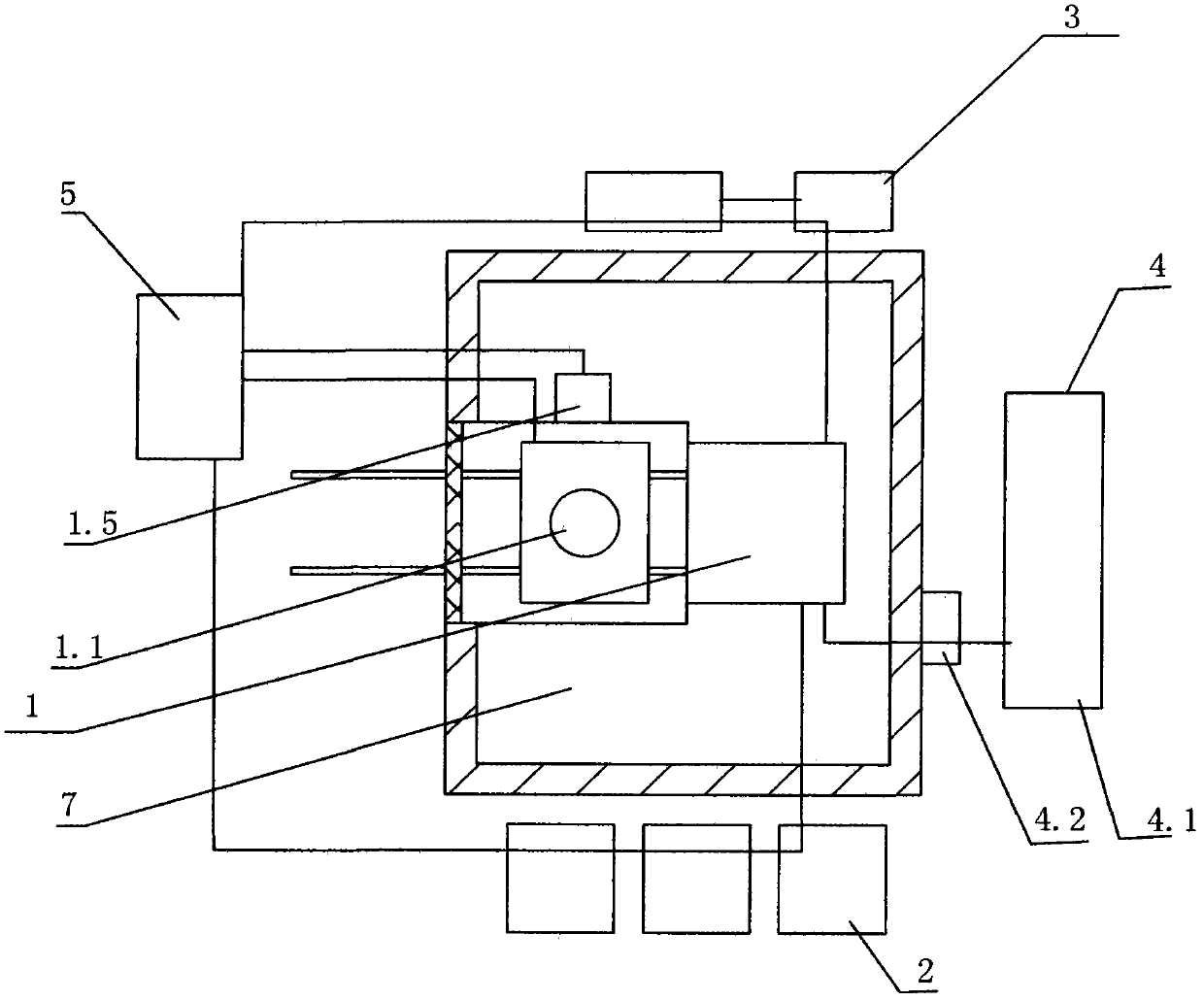

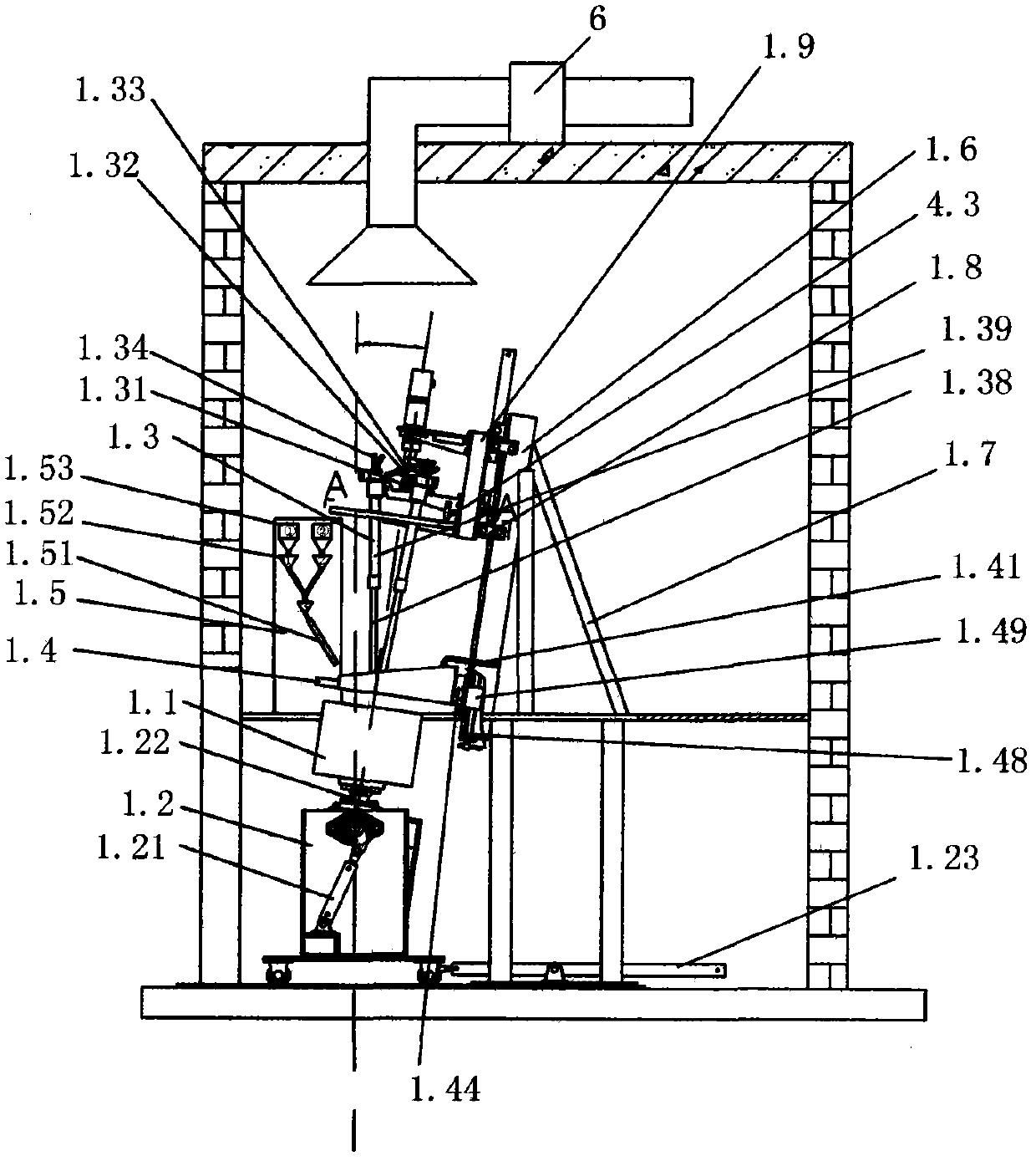

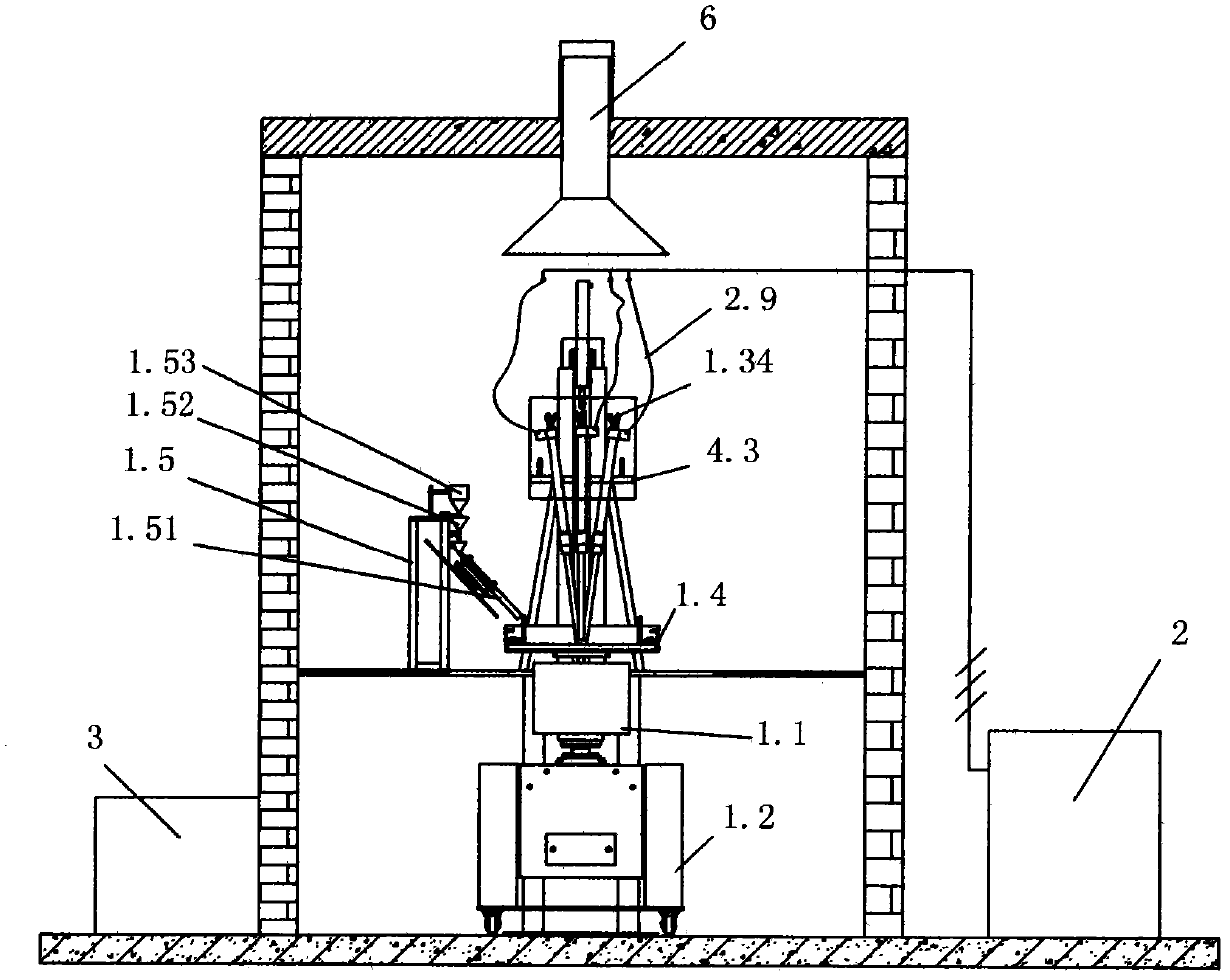

[0049] A quartz crucible high-temperature forming system, including a crucible melting host 1, an oil-immersed transformer 2, a hydraulic transmission system 3, a cooling system 4, a control system 5, an exhaust system 6, a crucible melting chamber 7, and a crucible melting host 1 Located in the crucible melting chamber 7, the exhaust system 6 is located at the top of the crucible melting chamber 7; the crucible melting host 1 is connected to the control system 5 through electrical signals and information signals, and the oil-immersed transformer 2 is connected to the crucible melting through electric wires The main machine 1 is connected, the hydraulic transmission system 3 is connected with the crucible melting main machine 1 through the connecting rod, the cooling system is connected with the crucible melting main machine 1 through the cooling liquid pipe, and the exhaust system is located on the crucible melting main machine 1.

[0050] The crucible melting host 1 includes ...

Embodiment 2

[0063] See Figure 6 , a mold 1 for manufacturing a crucible by a vacuum heating coating method, located below the electrode 1.3, including a crucible mold 1.11, a quartz fiber layer 1.12, a cooling water jacket 1.13, the crucible mold 1.11 is composed of high-purity graphite, and the crucible mold 1.11 The shape of the inner wall corresponds to the shape of the crucible, the quartz fiber layer 1.12 is outside the crucible mold 1.11, the cooling water jacket 1.13 is outside the quartz fiber layer 1.12, and also includes a ring-shaped cover 1.14, which is above the crucible mold 1.11. The outer diameter of the cover 1.14 is equal to the outer diameter of the crucible mold 1.11, the inner diameter of the annular cover 1.14 is equal to the inner diameter of the crucible mold 1.11, and the annular cover 1.14 uses a high temperature resistant alloy. There is an annular concave platform inside the upper port of the crucible mold 1.11, and there is an annular convex platform inside t...

Embodiment 3

[0065] See Figure 5 , an oil-immersed transformer 2 applied to the process of vacuum coating to produce arc quartz crucibles, comprising a transformer body composed of a static iron core 2.1, a moving iron core 2.2 and a coil 2.3 wound therebetween. The first layer is provided with an oil tank 2.4, and a cooling oil circulation device is connected to the oil tank 2.4.

[0066] The cooling oil circulation device includes an oil pipe 2.5 connected to the oil tank, and the oil pipe 2.5 is respectively provided with a cooler 2.6 and an oil pump 2.7. The oil-immersed transformer 2 is connected to the electrode 1.3 through a wire 2.9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com