Design, production and use of a new type of free-fall hammer

A free-falling and free-flowing technology, which is applied to foundation pile detection of highway and bridge engineering, port engineering, and construction engineering, can solve the problems of increased detection cost, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

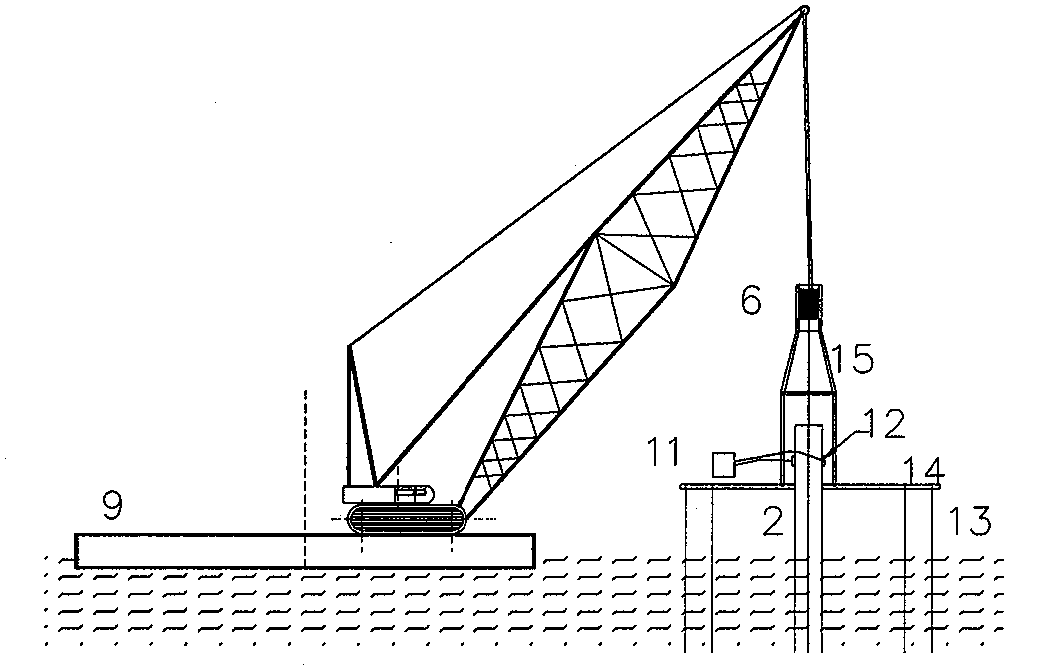

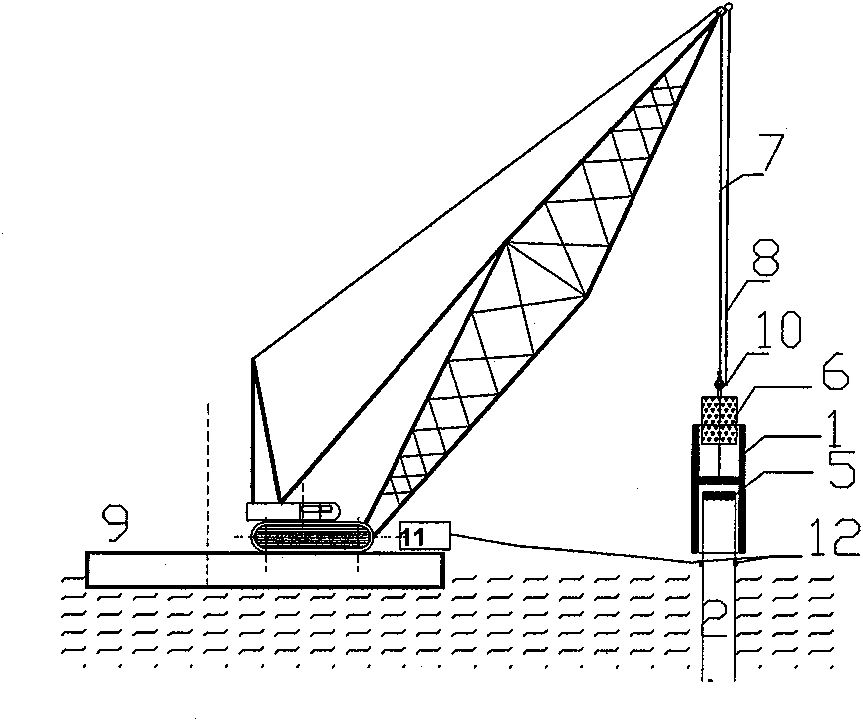

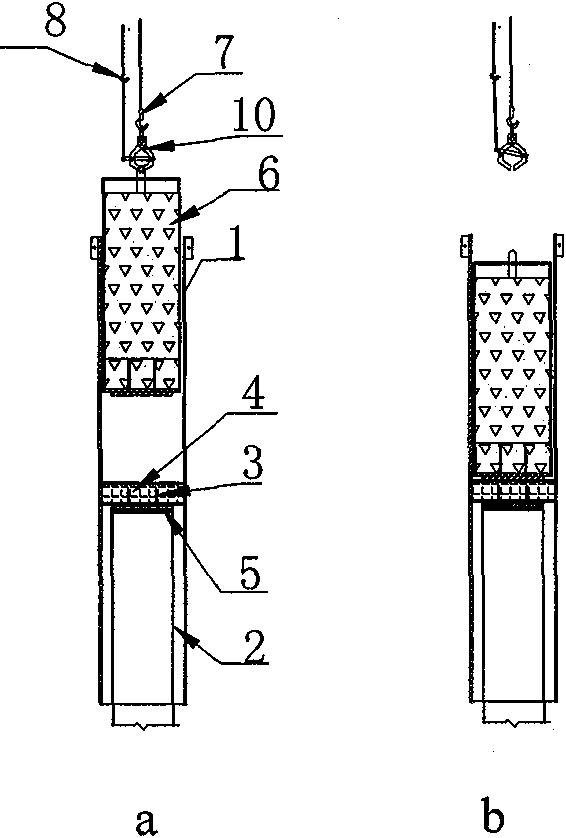

[0020] Attached below Figure 1-3 The present invention is further described in detail.

[0021] A new type of free-fall hammer for foundation pile dynamic tests, including a sleeve 1 and a hammer 6; the sleeve 1 is placed on the top of the test pile 2, so that the sleeve partition 3 presses the top of the test pile, and the lower part of the sleeve 1 is close to the top of the test pile. Test the pile body to ensure the verticality and stability of the sleeve 1; the upper part of the sleeve partition 3 is provided with a hammer pad 4, and the pile pad 5 is provided between the lower part of the sleeve partition 3 and the top of the test pile 2. Hammer 6 is placed on the inside of sleeve 1, with the top of sleeve 1 as the guide device when hammer 6 falls, to keep smooth and safe when falling. The sleeve 1 can be a steel pipe with a steel dividing plate welded in the middle. Hammer pad 4 is prepared by steel wire rope and wooden beam. The pile mat 5 is prepared from planks. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap