A water piling device

A technology of piling device and pile cap, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of high mechanical requirements, increased construction cost, high cost, etc., and achieve low mechanical requirements, simple construction and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

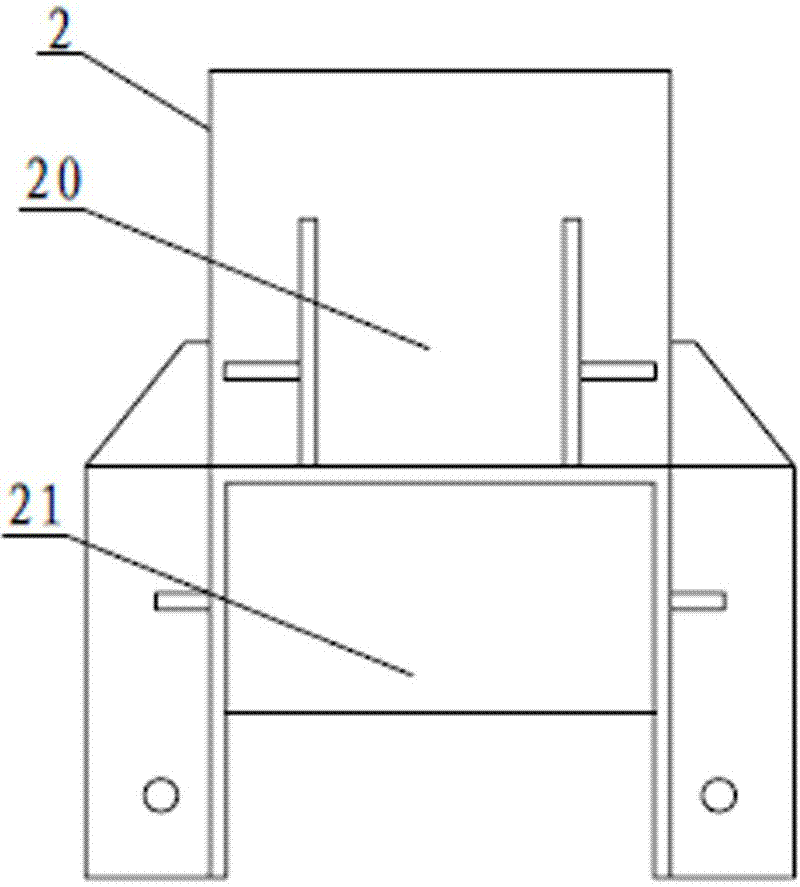

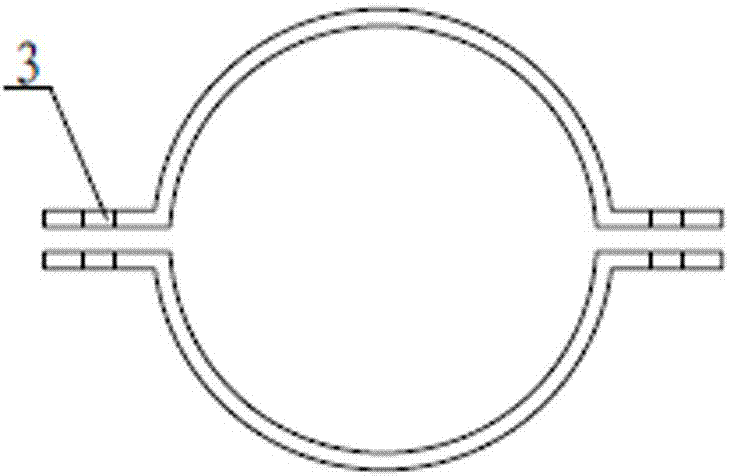

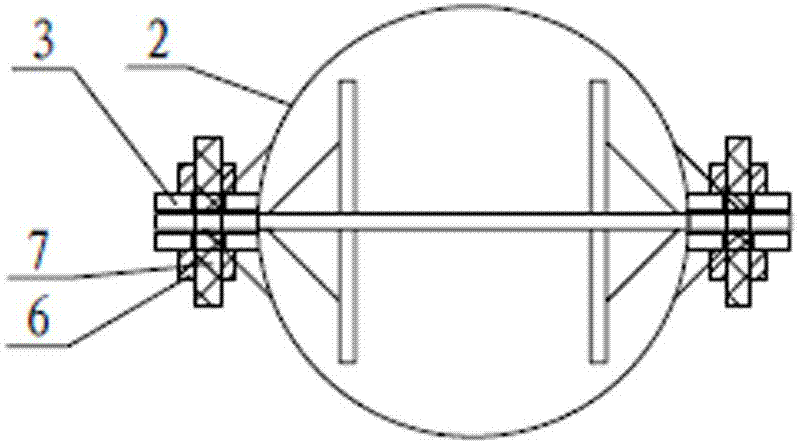

[0017] Such as Figures 1 to 5 As shown, the water piling device according to this embodiment includes a prestressed pipe 1 for forming a pile, a pile cap 2 having a receiving portion 21 for accommodating the top end of the prestressed pipe 1, and a pile cap 2 for connecting the pile cap 2 with the prestressed pipe 1. The hoop 3 fixed to the stress tube 1 and the vibrating hammer 4 can generate vibration. One end of the vibrating hammer 4 has a first connecting part 40 connected to the pile cap 2, and the other end has a first connecting part 40 connected to the hanger 5. Two connection parts, wherein hanger 5 is the hanger of existing water floating hanger.

[0018] During construction, make a pile cap 2 and a hoop 3 according to the size requirements of the pipe pile, use the hoop 3, fix the prestressed pipe 1 and the pile cap 2 as the pipe pile through the threaded steel 7 and the nut 6, and then use the vibrating The first connecting part 4 of the pulling hammer 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com