A lightweight material filler with a rigid base

A technology of lightweight materials and fillers, applied in building materials, building components, floor slabs, etc., can solve the problems of low hollowness of hollow floors, difficult pipeline layout, inconvenient construction, etc., to achieve good economy and applicability, The effect of good thermal insulation, convenient transportation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is realized in the following manner:

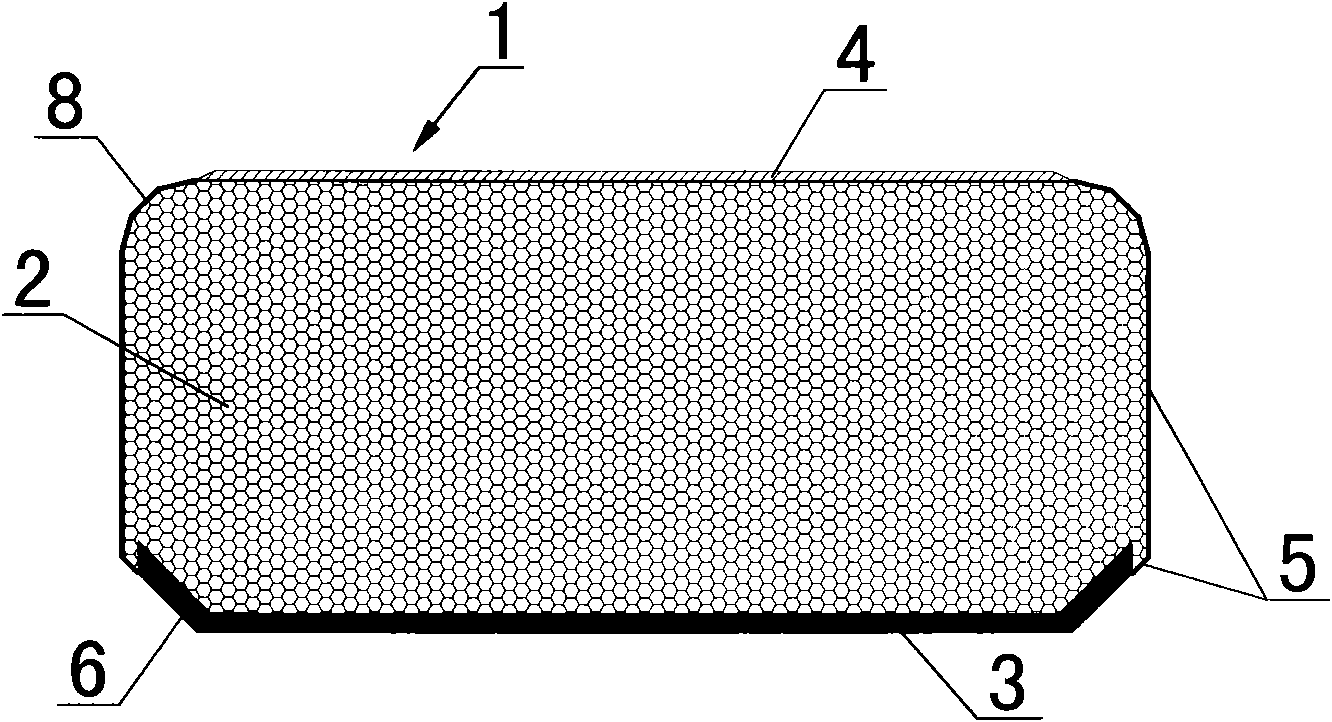

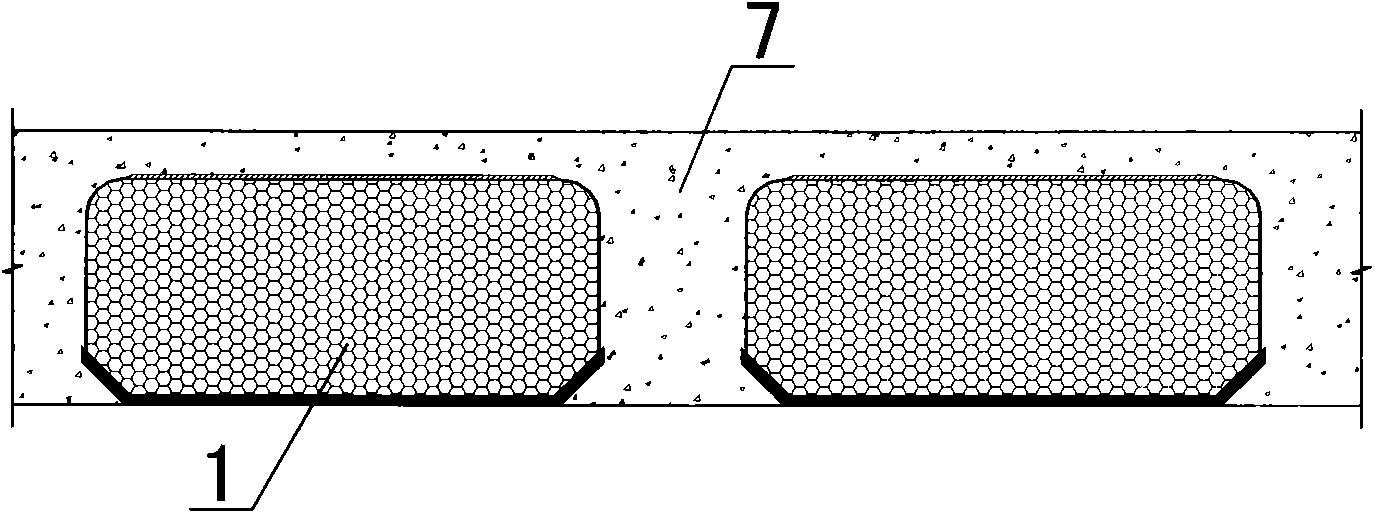

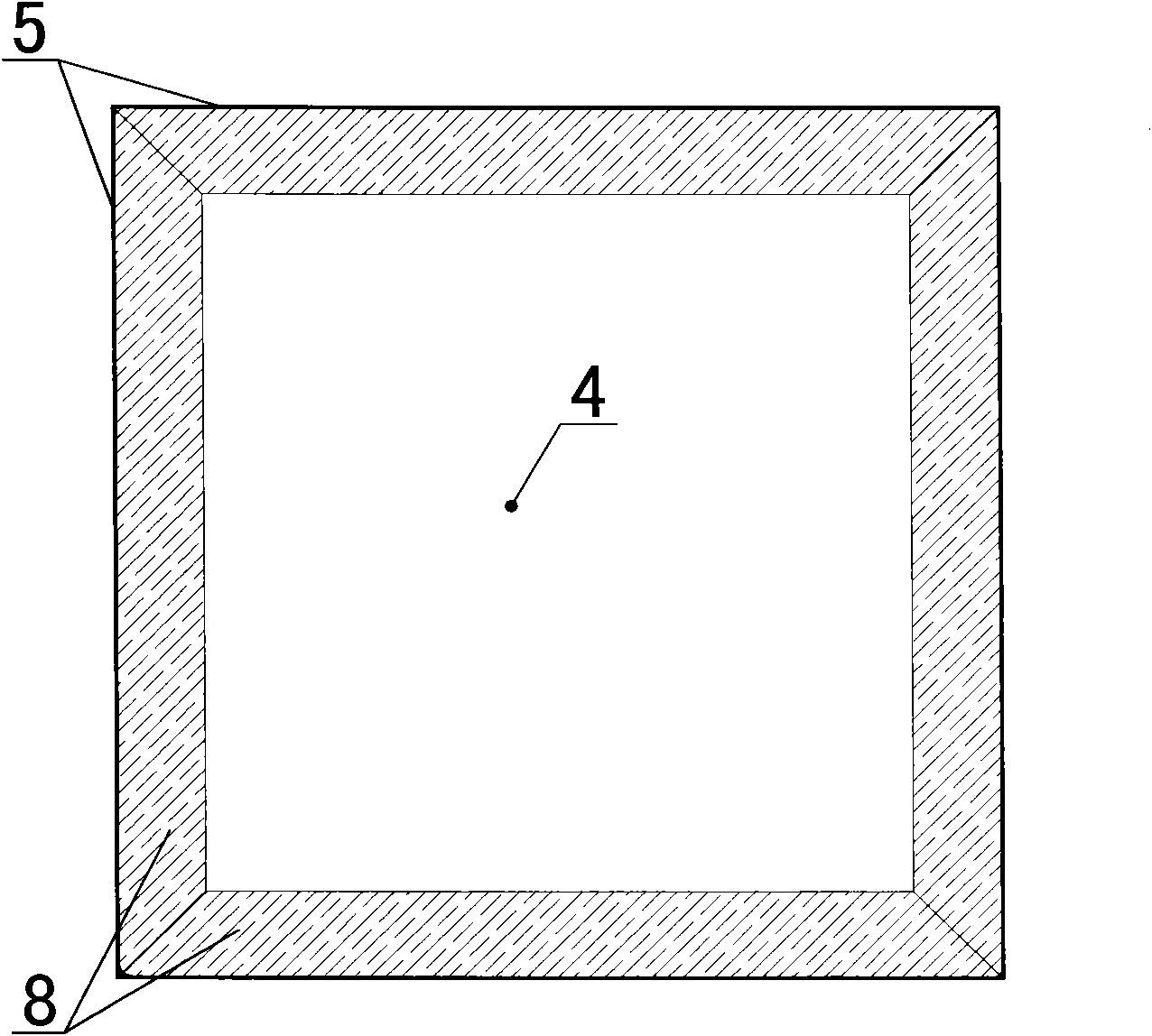

[0029] exist figure 1 , figure 2 In the shown embodiment, a lightweight material filler with a rigid base, the filler (1) comprises a body (2) of lightweight foam material, a rigid base (3), a reinforcing layer (4) and The isolation layer (5), the body (2) is installed on the hard base (3), the upper surface of the body (2) has a reinforcement layer (4), and the body (2) is separated from the hard base (3) and the reinforcement layer There is also an isolation layer (5) on the remaining exposed outer surface of (4) except the contact surface, and the periphery of the hard base (3) is upturned (6), wrapping the bottom of the body (2) on the hard base ( 3), the filler (1) is buried in the concrete (7), and the hard base (3) of the filler (1) is exposed in the lower surface of the concrete floor.

[0030] exist figure 1 In the shown embodiment, the light foaming material of the main body (2) is extruded board,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com