A new structure of anti-vibration bearing seat

A technology for bearing seat and vibration isolation, which is applied to the rigid support of bearing components, bearing elements, shafts and bearings, etc., and can solve the problems of long and thin shaft and bearing fit gap wear, large adaptive range, and large shaft radial error And other problems, to achieve the effect of prolonging the service life, good vibration isolation effect, and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

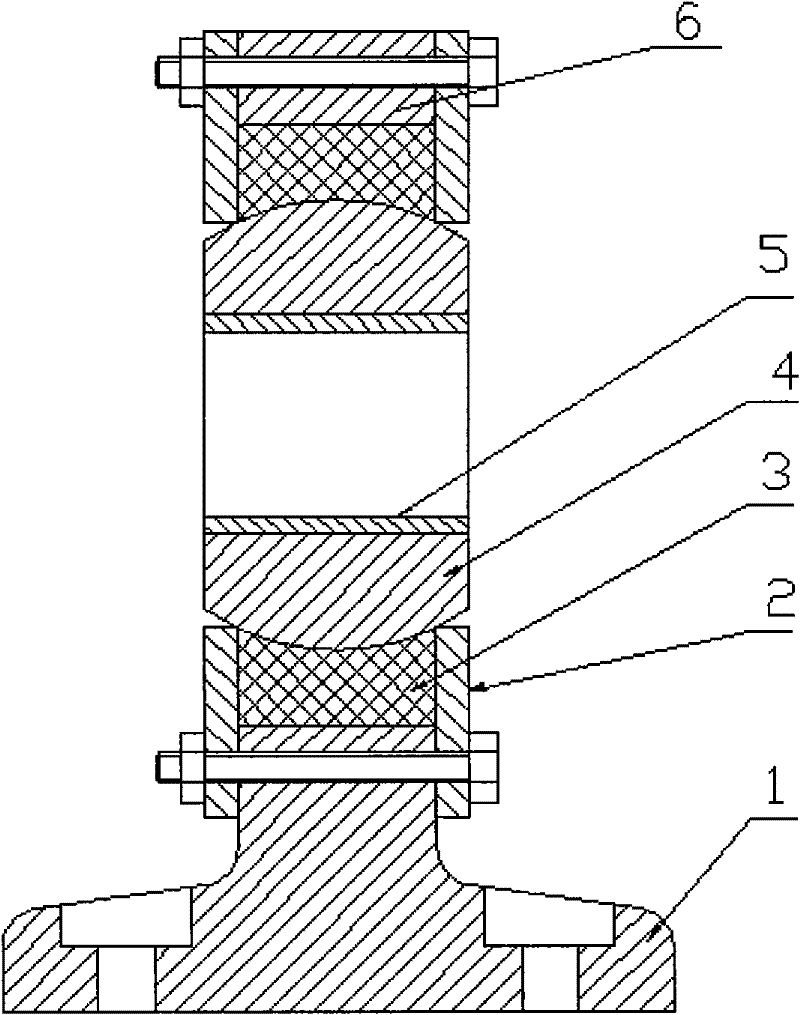

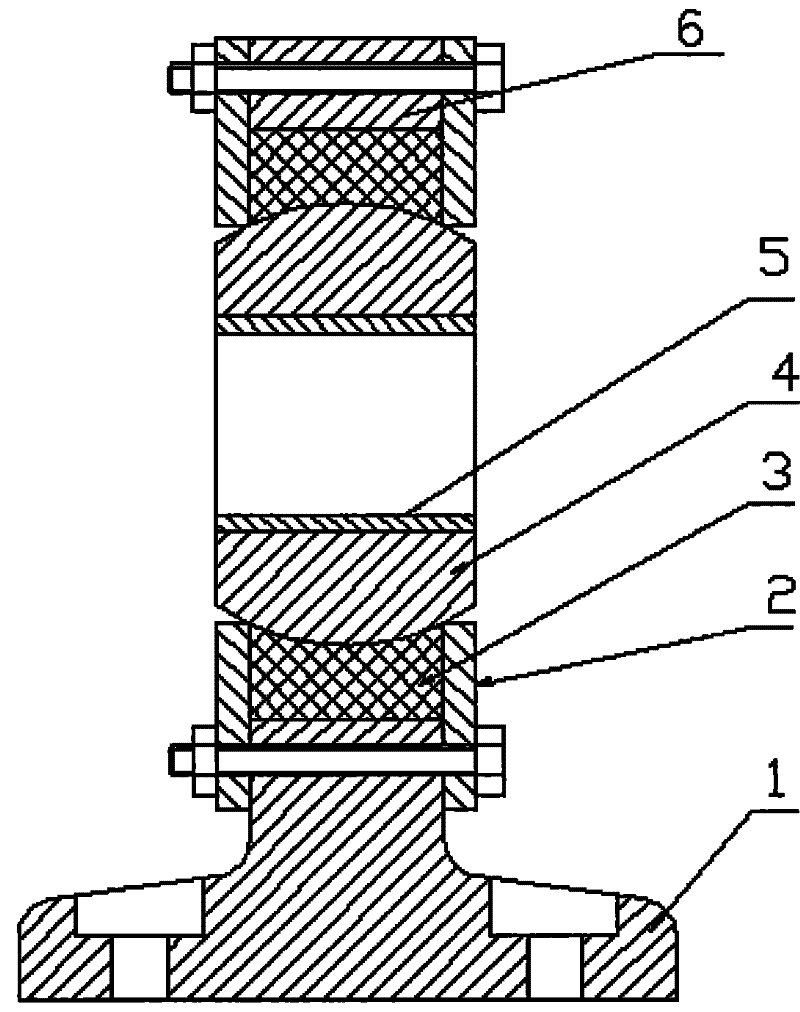

[0009] As shown in the figure: the structure of the bearing seat has a bearing (5) connected with the spherical bushing (4), and the bearing (5) spherical bushing (4) is connected with the rubber vibration-absorbing ring (3) and loaded into the bracket (1 ) and the large hole of the support body (6), are respectively fixed on the support (1) by bolts with two blocking covers (2), and the blocking covers (2) are connected with the rubber shock-absorbing collar (3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com