A dedicated grounding device for high-voltage shunt capacitors in substations

A technology of grounding device and capacitor, which is applied in the direction of substation grounding arrangement and connection contact material, which can solve the problems of long installation time, small grounding wire, and weak connection, etc., and achieve the effect of high work efficiency and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

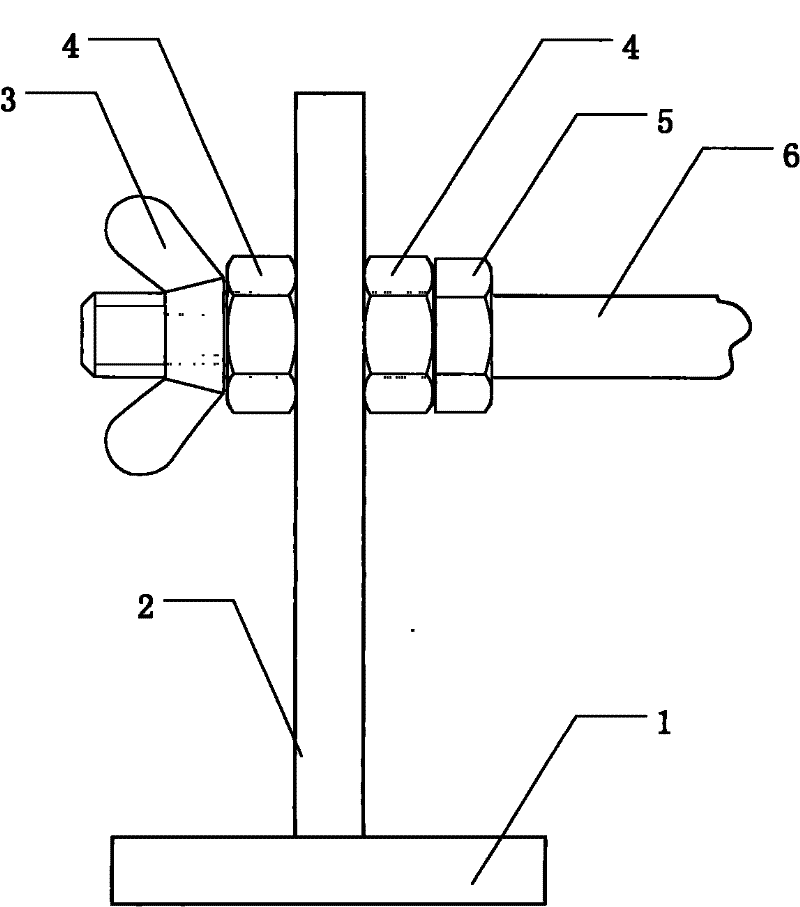

[0008] Such as figure 1 As shown, a special grounding device for high-voltage shunt capacitors in substations is mainly composed of a grounding pile base 1 and a grounding pile body 2 welded thereon. Wing nuts 3 and ground wire joint bolts 5 are installed on the outside respectively.

[0009] When in use, since the grounding pile base and the grounding flat iron are welded, only the grounding wire 6 needs to be inserted into the grounding pile body 2 through the grounding wire joint bolt 5, fixed by the transition nut 4, and then tightened by the wing nut 3. It can be fixed. When removing the grounding wire 6, first remove the wing nut 3, then remove the transition nut 4, and then pull the grounding wire 6 out of the grounding pile body 2 through the grounding wire joint bolt 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com