Cylinder surface treatment device

A technology for surface treatment devices and cylinders, applied to sealing devices, cylinders, cylinder heads, etc., can solve the problems of increasing the supply cost and storage cost of cover parts 107, increasing the man-hours of changing cover parts 107, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

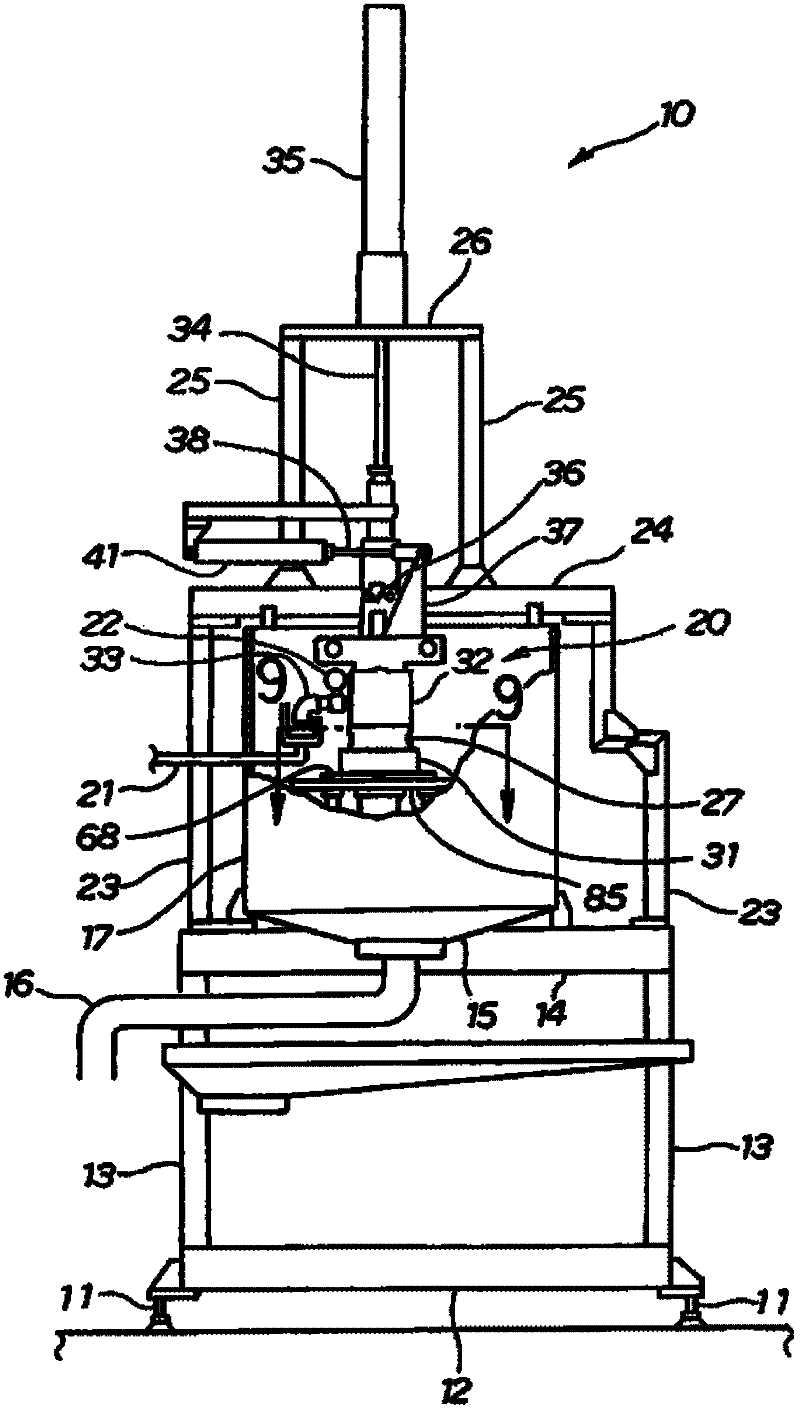

[0033] Such as figure 1 As shown, the cylinder surface treatment device 10 of this embodiment has: a base 12 with an adjustment device 11 , a lower column 13 erected from the base 12 , and an intermediate support member arranged at the upper end of the lower column 13 14. The tray 15 that is supported by the intermediate support member 14 and collects the treatment liquid, the treatment liquid discharge pipe 16 that discharges the treatment liquid collected in the tray 15 to the outside, and the cylinder member (囲い材材) 17 provided on the tray 15, The surface treatment part 20 provided on the intermediate part support member 14 so as to be surrounded by the cylindrical part 17, the drain pipe 21 provided on the surface treatment part 20 for guiding the drainage from the upper part of the surface treatment part 20, The treatment liquid detection part 22 which monitors the discharge of the liquid discharge pipe 21, the intermediate column 23 erected from the intermediate support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com