Mesh belt type air energy dryer

An air energy drying and air energy technology, which is applied in dryers, progressive dryers, drying and other directions, can solve the problems of uneven air volume and temperature distribution, unstable drying temperature, and poor product quality. The effect of reducing heat source supply cost, improving drying effect and improving heat energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

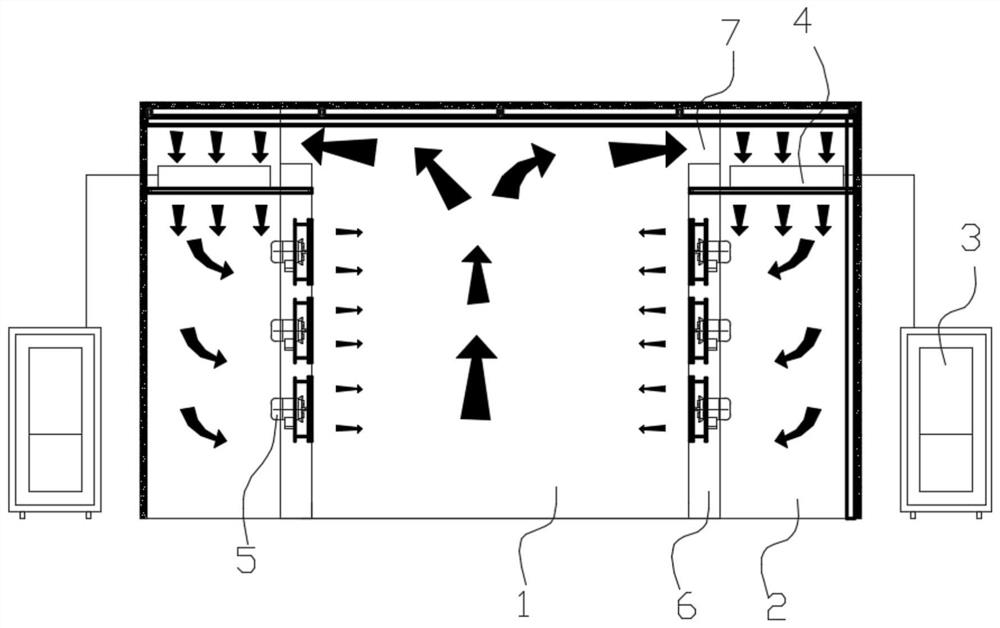

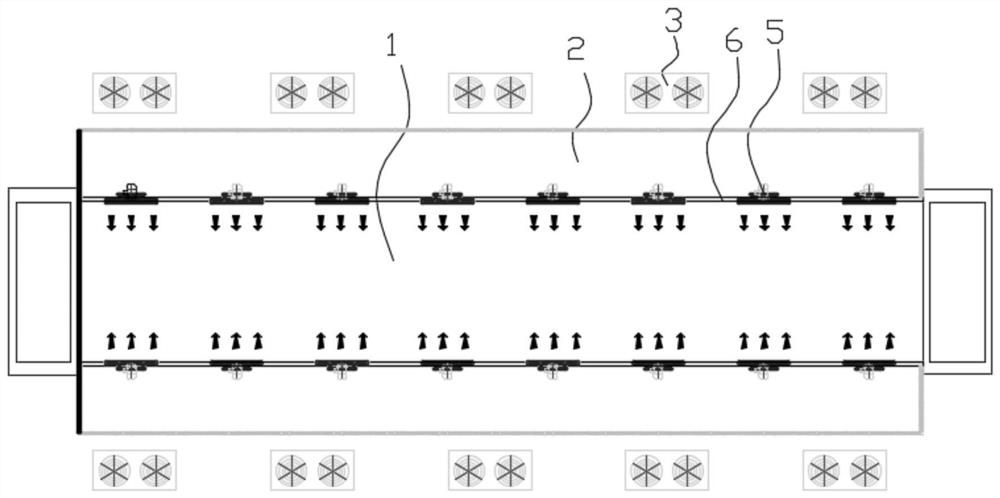

[0030] like figure 1 , figure 2 and image 3 As shown, a mesh belt type air energy dryer includes a drying chamber 1, an air chamber 2, an air energy host 3, an air energy condenser 4 and an axial flow fan 5, and the air chambers are arranged symmetrically on both sides of the drying chamber 1. 2. The drying chamber 1 and the air chamber 2 are separated by a partition 6, and the top of the air chamber 2 is provided with an air energy condenser 4, and the air energy condenser 4 is connected to the air energy host 3 arranged outside the air chamber 2;

[0031] A number of through holes are provided on the partition 6, and the through holes are distributed in a rectangular array. The through holes of the partitions 6 on both sides are symmetrically arranged, and the axial flow fan 5 is installed in the through holes, so that the air chamber can be blown by the axial flow fan 5. The hot air in 2 is accelerated to the drying chamber 1;

[0032] The top of the partition 6 is pro...

Embodiment 2

[0042] Embodiment 2 is a further optimization of Embodiment 1.

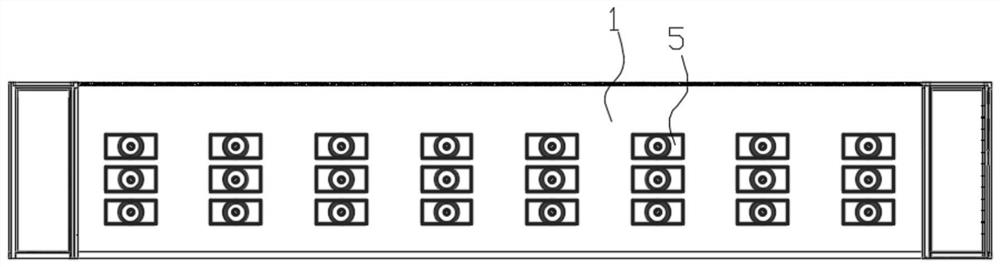

[0043] like Figure 4As shown, the drying chamber 1 is provided with a fixed mount 12. There are at least two fixed mounts 12. The mounting plate 13 that is slidably connected, that is, the mounting plate 13 slides up and down on the fixed frame 12, and the mounting plate 13 is connected with the horizontal conveying chain 10.

[0044] There are multiple mounting plates 13, and the multiple mounting plates 13 are distributed up and down on the fixed frame 12, and the mounting plates 13 are slidably connected with the horizontal conveying chain 10. The mounting plate 13 is provided with a driving device, which is connected to the horizontal conveying chain 10 , and the driving device is used to drive the horizontal conveying chain 10 to move left and right relative to the mounting plate 13 . The driving device is a hydraulic cylinder or an air cylinder.

[0045] The fixed frame 12 is provided with a driving dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com