Electric machine with multiple cooling streams and cooling method

A technology of cooling flow and cooling slots, applied in the direction of cooling/ventilation devices, electrical components, electromechanical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The examples to be described in detail below are preferred implementations of the present invention.

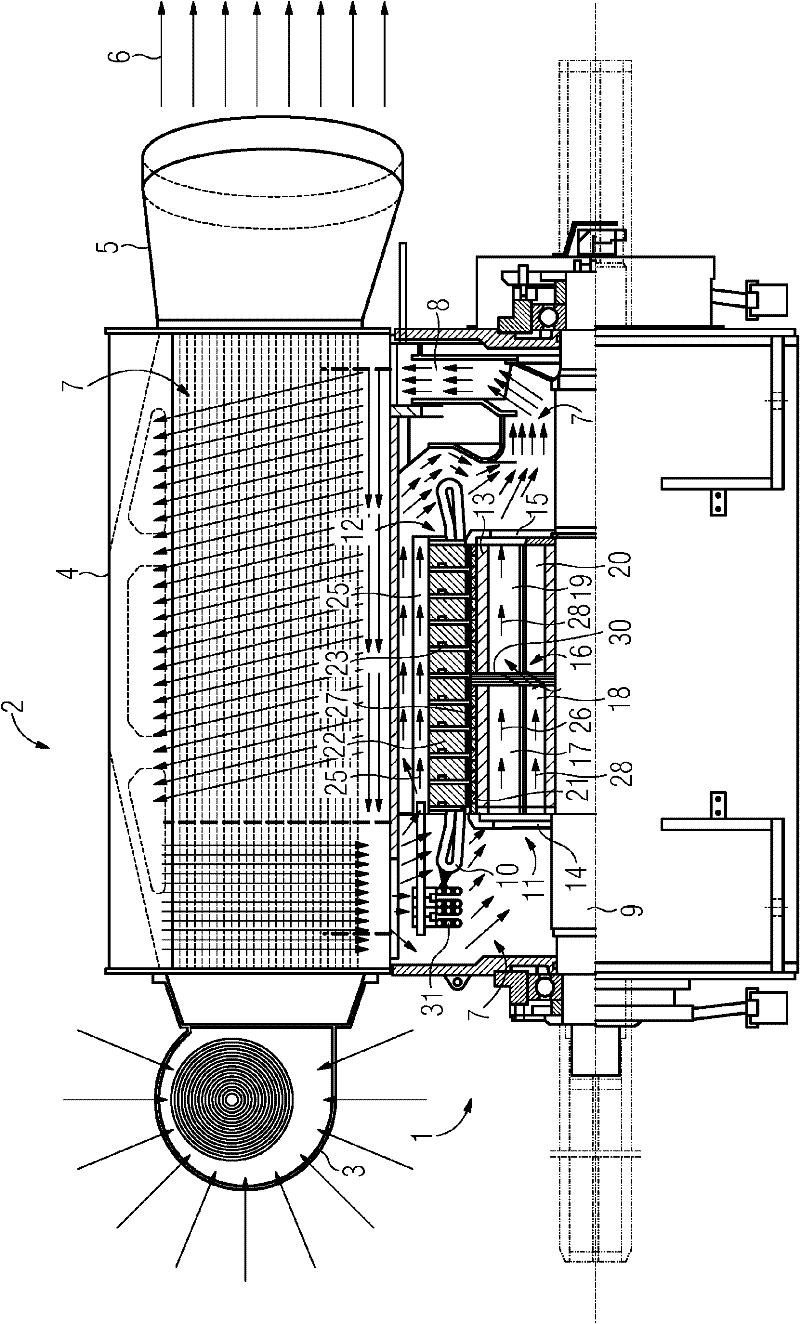

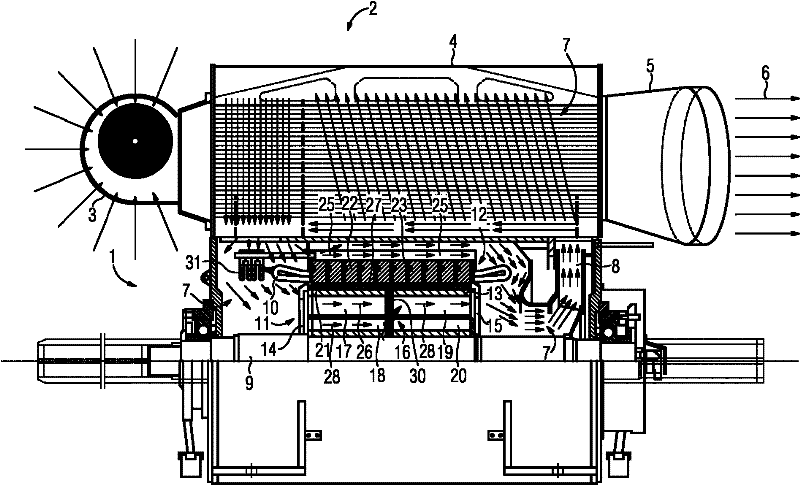

[0015] The drawing shows a generator 1 including a cooler 2 . The cooler 2 has a fan 3 to suck in cooling air and blow it into a heat exchanger 4 . The air in the heat exchanger flows to the outside through the exhaust pipe 5 . This forms an external cooling circuit.

[0016] The heat exchanger 4 cools the closed internal cooling circuit 7 via the external cooling circuit 6 . Driving the internal cooling circuit 7 is a shaft fan 8 mounted on the B side of the crankshaft 9 of the generator 1 . Starting from the fan 8 , the internal cooling circuit passes through the heat exchanger and enters the winding end region on the generator A side (drive side). The internal cooling circuit bypasses the winding heads 10 and the winding circuit 31 and passes through the rotor 11 and the stator 12, as will be described in detail below. Finally, the coolant (in particular air) p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com