a blending mixer

A blending and stirring paddle technology, applied in mixers with rotary stirring devices, chemical instruments and methods, dissolution, etc., can solve problems such as failure, destruction of cell survival rate, poor survival rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

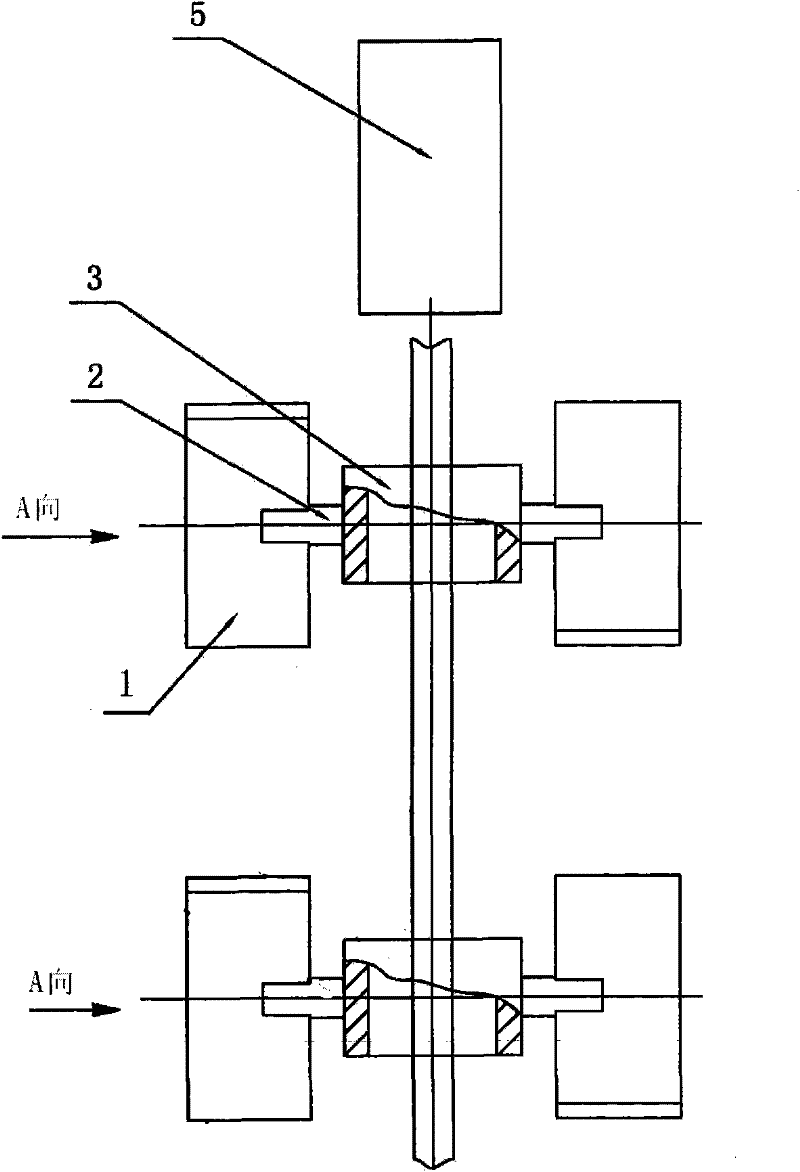

[0010] Combined with the accompanying drawings:

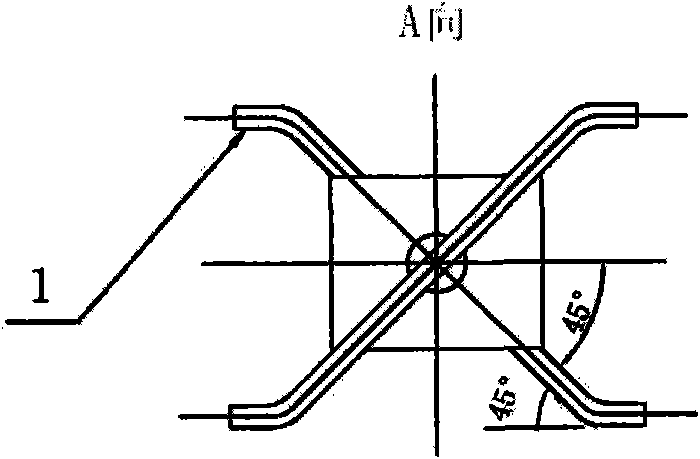

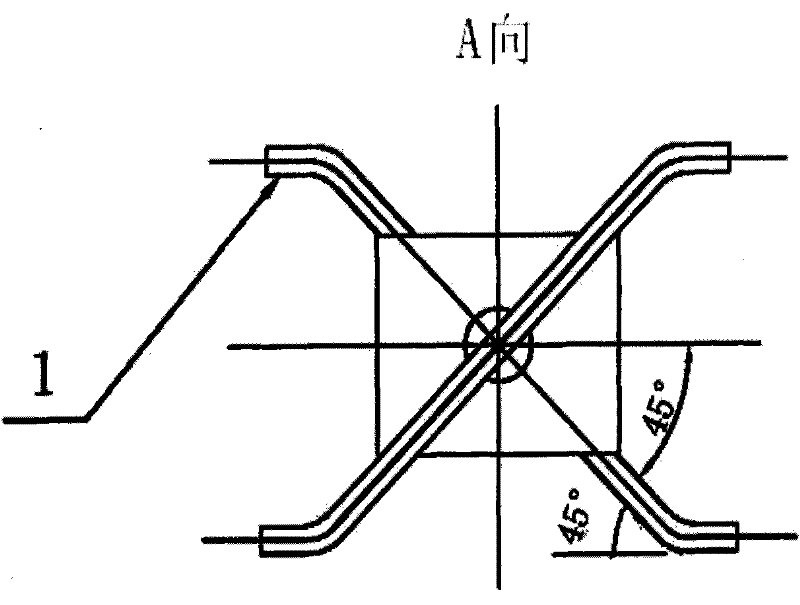

[0011] 1), such as ( figure 1 ) shows a stirring paddle system composed of 1 blade, 2 connecting rods, and 3 shaft sleeves (each stirring paddle system has two symmetrical sets of blades). Because 1 blade adopts (such as figure 2 ) "Ten" windmill, when the 5th motor drives the 4th stirring shaft to run clockwise, the 1 blade will also rotate clockwise due to the stress of the liquid, so as to achieve sufficient stirring to make the oxygen evenly distributed or heat and cool to achieve Uniform effect.

[0012] 2), such as ( figure 2 ) shows that the blades of the "ten" windmill are used and each end has a 45-degree cocking with an acute angle, and the cocking is parallel to the structure of the same "ten" connecting the bisector of the top angle, When the agitator is running, the blade avoids contacting the cells in the mixture with the sharp front, but gently touches the cells in the mixture with the flat surface of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com