A molybdenite flotation collector

A collector, molybdenite technology, applied in flotation, solid separation and other directions, can solve problems such as failure to find, and achieve the effects of improving molybdenum recovery rate, easy operation and simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A molybdenite flotation collector of the present embodiment is formed by mixing butyl oleate and light diesel oil, and the volume percentage of butyl oleate in the collector is 10%.

Embodiment 2

[0014] A molybdenite flotation collector of this embodiment is formed by mixing butyl oleate and light diesel oil, and the volume percentage of butyl oleate in the collector is 20%.

Embodiment 3

[0016] A molybdenite flotation collector of the present embodiment is formed by mixing butyl oleate and light diesel oil, and the volume percentage of butyl oleate in the collector is 15%.

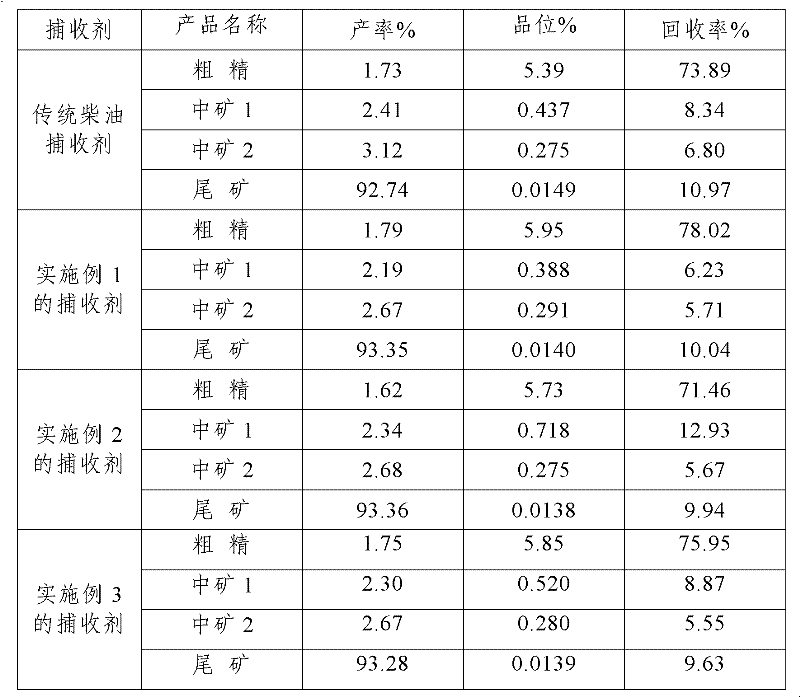

[0017] Collector performance comparison of the present invention and traditional diesel oil collector:

[0018] Adopt the collector of traditional diesel oil collector and embodiment 1 to 3 respectively, carry out the flotation of molybdenite according to conventional method, the consumption of collector is 100g / t (every ton of molybdenite adds 100g collector) , JM-208 is a foaming agent, the dosage is 80g / t (add 80g foaming agent per ton of molybdenite), and the flotation results are shown in the table below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com