Vertically lifting type antifreeze solution spraying device and use method thereof

A spraying device and vertical lifting technology, which is applied in the direction of liquid spraying device, spraying device, device for coating liquid on the surface, etc., can solve the problems of antifreeze waste, spraying blind area, excessive spraying volume, etc., and avoid liquid flow crossing Interference, meet the spraying requirements, clear effect of spraying area

Active Publication Date: 2011-12-07

TAIYUAN UNIV OF TECH

View PDF7 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Automatic spraying is the development direction of antifreeze spraying, but the automatic spraying system currently designed and in use is still not perfect, and there are many problems, such as the inability to accurately stop spraying at the connecting gap of the carriage, resulting in waste of antifreeze and corrosion of the connecting hook; Due to the movement of the carriage, the front and rear ends of the carriage are sprayed unevenly, and even a spray blind area is generated; when the moving speed of the carriage changes or the ambient temperature changes, the spraying amount cannot be adjusted in time, so that the spraying amount is too large or too small, or the antifreeze is wasted, or freezing occurs. The nozzle design position is unreasonable, and the spraying liquid crosses and interferes, resulting in uneven spraying; as the size and height of the carriage change, the nozzle position cannot be adjusted, resulting in the sprayed antifreeze overflowing the carriage, resulting in waste or the antifreeze cannot cover the upper side of the carriage. Causing frozen cars; and pipe blockage problems after a short period of sprinkler use

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach 2

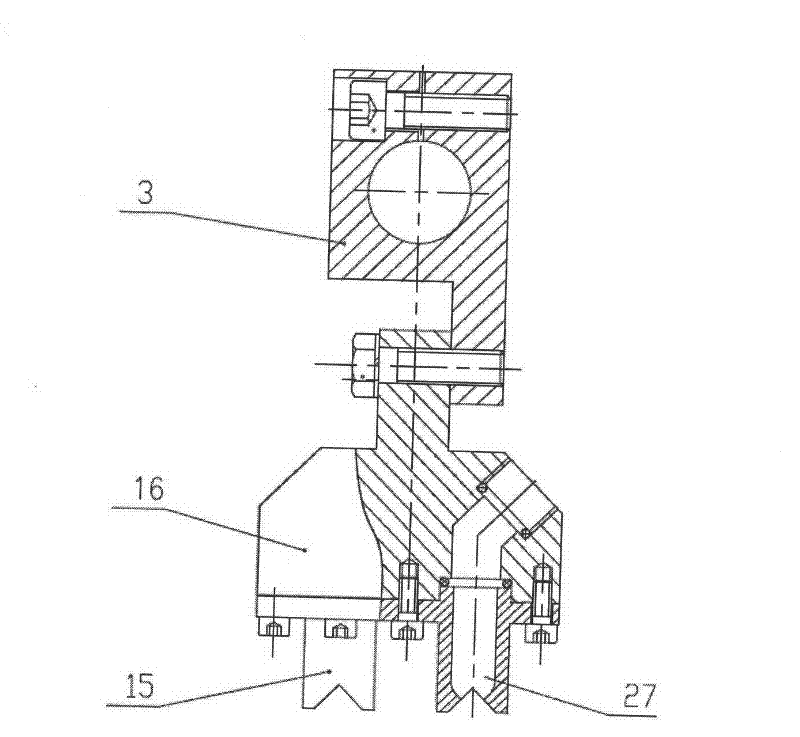

[0029] Embodiment 2: 4 groups of nozzle seat assemblies are sequentially installed on the nozzle rotating shaft 4 at intervals of 300mm;

Embodiment approach 3

[0030] Embodiment 3: 4 groups of nozzle seat assemblies are sequentially installed on the nozzle rotating shaft 4 at intervals of 280mm;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

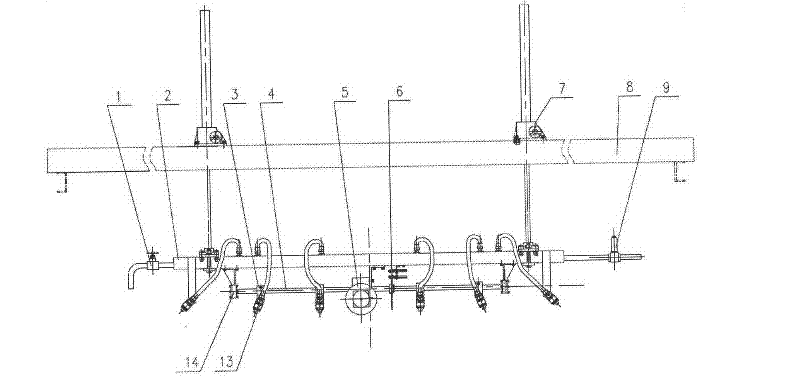

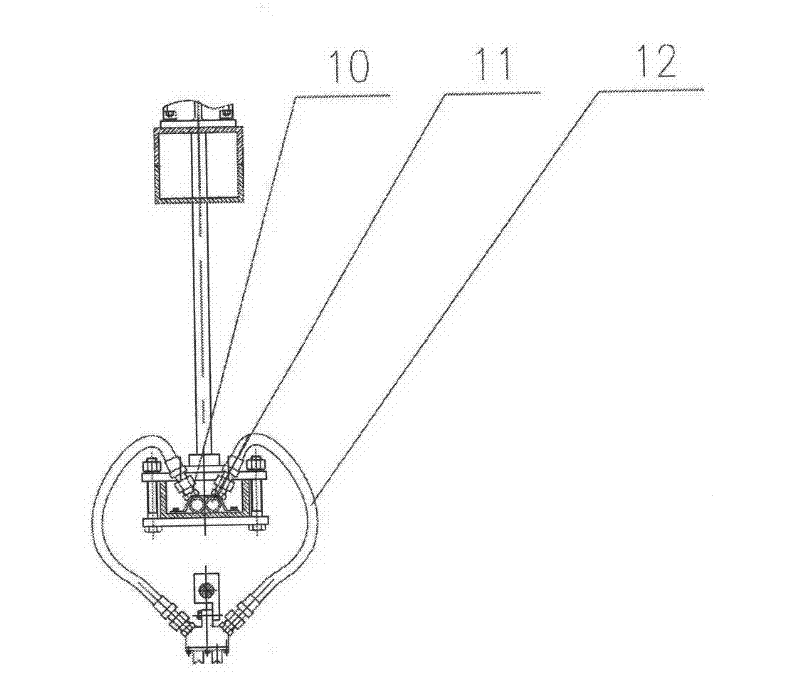

The invention relates to a vertically lifting type antifreeze solution spraying device and a use method thereof and belongs to the technical field of mechanical design and control. The invention particularly relates to a technical scheme of an antifreeze solution spraying device which is capable of lifting vertically and can be used for efficiently and uniformly spraying the antifreeze solution onto five inner surfaces of a carriage of a coal train and a use method of the device. The antifreeze solution spraying device is characterized by comprising a support beam, a rotating beam, a verticallifting mechanism, a nozzle turning mechanism, a nozzle base assembly, an angular displacement sensing mechanism, a pipeline system and a control system. The antifreeze solution spraying device can uniformly spray the antifreeze solution onto the inner walls of the carriage in all directions, but stops spraying the antifreeze solution onto the clearances between carriages. When a high-altitude device, a head end and a maintenance car pass by, the whole antifreeze solution spraying device is lifted up vertically and stops spraying the antifreeze solution. The parameters, such as nozzle type, quantity, rotating speed, rotating direction and the like, can be automatically adjusted according to the conditions such as the indentified carriage position, moving direction, moving speed, ambient temperature and the like, thereby promoting the spraying effect, the spraying efficiency and the use ratio of the antifreeze solution.

Description

technical field [0001] The invention relates to a vertical lift type antifreeze spraying device and its use method, belonging to the technical field of mechanical design and control, and in particular to a vertical lift type that can efficiently and evenly spray antifreeze to the inner surface of coal train compartments at different heights. A technical proposal of an antifreeze spraying device and a method for using the same. Background technique [0002] The railway is the main channel for coal transportation in my country. The coal transported by coal transportation enterprises contains moisture, and the trains will freeze during transportation in winter. The problem of coal transportation and frozen trucks has brought huge economic losses to departments such as mines, roads, and ports. The main forms of loss are: the loss of residual coal from frozen vehicles, the waste of transport capacity caused by the round-trip transportation of residual coal from frozen vehicles, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B05B9/00B05B12/00B05B15/02B05B15/08B05D1/02B05B15/68

Inventor 牛志刚程建明范松张晓东王铁

Owner TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com