Cycloid propeller eccentric circle control mechanism

A technology of control mechanism and cycloidal propeller, which is applied in the direction of control starting method, aircraft transmission device, aircraft power transmission, etc., can solve the problems of difficult to realize instantaneous variable vector thrust, large and complex structure, mechanism friction loss, etc., and achieve weight Lightweight, high mechanical efficiency, and low mechanical friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

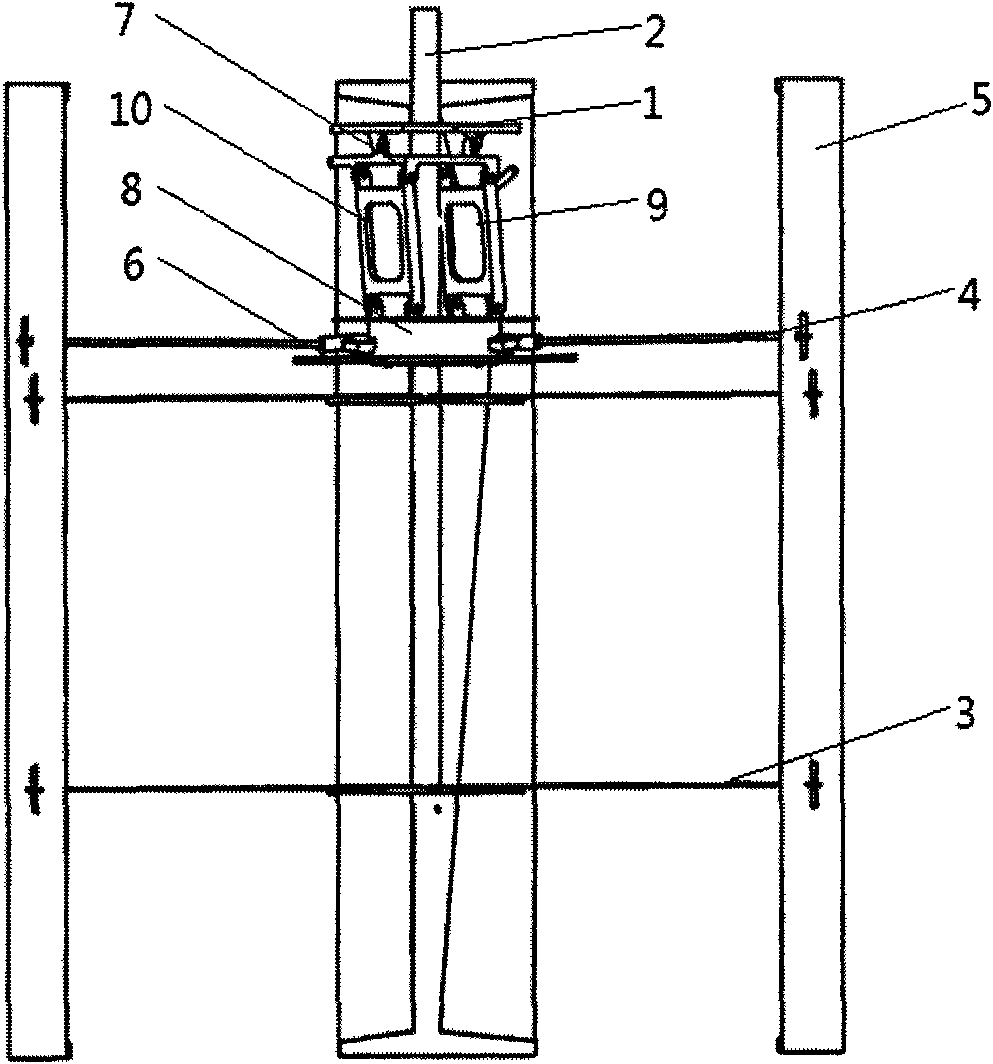

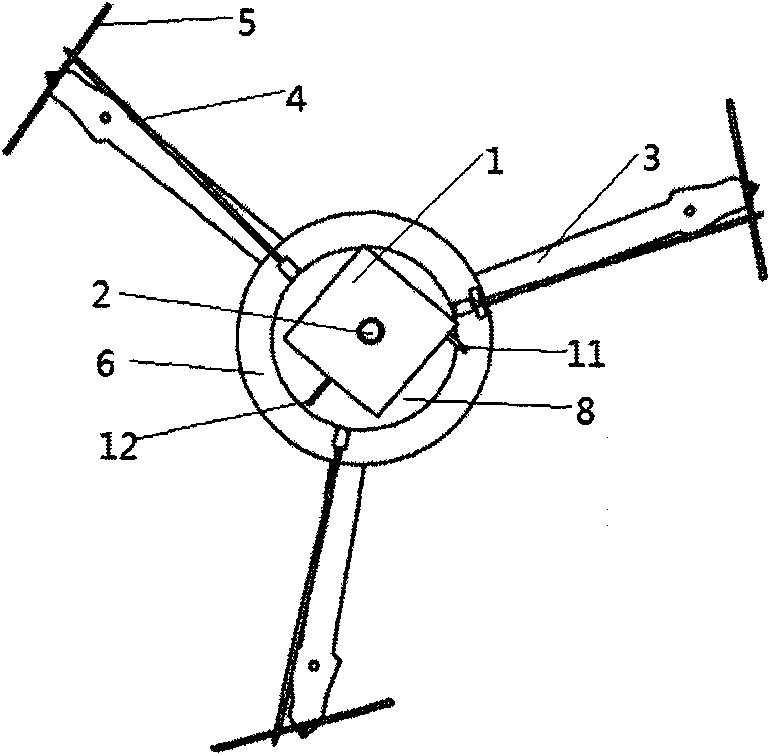

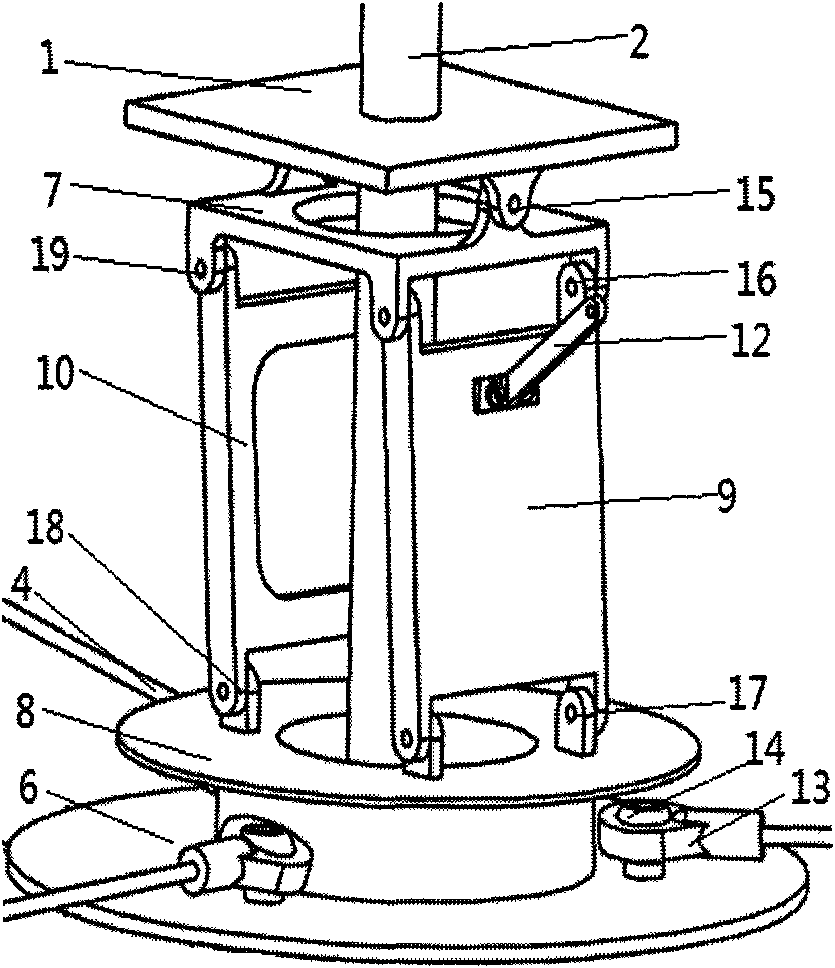

[0052] This embodiment is a cycloidal propeller control mechanism for micro-aircraft. Including base 1, cycloidal propeller rotating shaft 2, blade bracket 3, control rod 4, blade 5, chassis 6, upper end plate 7, lower end plate 8, first connecting plate 9, second connecting plate 10, upper end plate control The rocker arm 11, the first connecting plate controls the rocker arm 12. The base 1 is square and adopts aluminum alloy material, such as Image 6 , as shown in 7. The center of base 1 has the installation hole of cycloid paddle rotating shaft 2. There are a pair of lugs connected to the upper end plate 7 at the symmetrical sides of the lower surface of the base 1. The upper end plate 7 is connected to the lugs through a pin shaft, and the first rotation is formed by the pin shaft connection with the upper end plate 7. Deputy 15.

[0053] Both the cycloidal propeller rotating shaft 2 and the propeller bracket 3 are made of aluminum alloy materials, such as Figure 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com