Three-dimensional moment limiter for crane and crane including same

A crane, three-dimensional force technology, applied in the direction of crane, transportation and packaging, load hanging components, etc., can solve the problem of inability to understand the working state of the crane, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in combination with principle diagrams and specific operation examples.

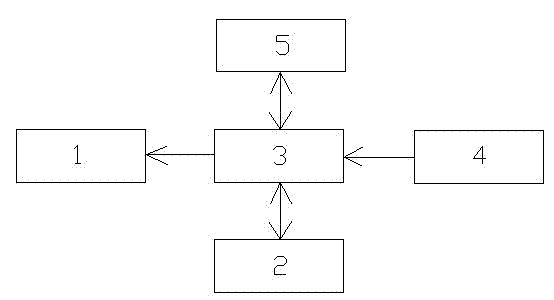

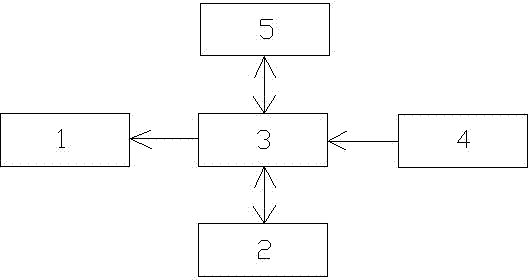

[0019] Such as figure 1 As shown, the three-dimensional moment limiter of the crane of the present invention specifically includes a display module 1, a storage module 2, a calculation control module 3, and a detection module 4 that are connected to each other. The detection module 4 includes an angle sensor, an oil pressure sensor, a tension sensor, and the like. The calculation control module 3 calls the main components of the current crane pre-stored in the storage module 2 based on Direct3D and OpenGL technology to perform 3D modeling. Exported from the design software, according to the current setting parameters of the crane detected by the detection module 4, it is assembled into a 3D model that is the same as the crane in the actual scene, and the work is simulated in real time according to the product model, operating conditions, operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com