Intelligent operation remote monitoring management system and method for unmanned rolling machine cluster

A remote monitoring and unmanned driving technology, applied in control/regulation systems, motor vehicles, non-electric variable control, etc., can solve problems such as heavy tasks, dusty, bumpy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

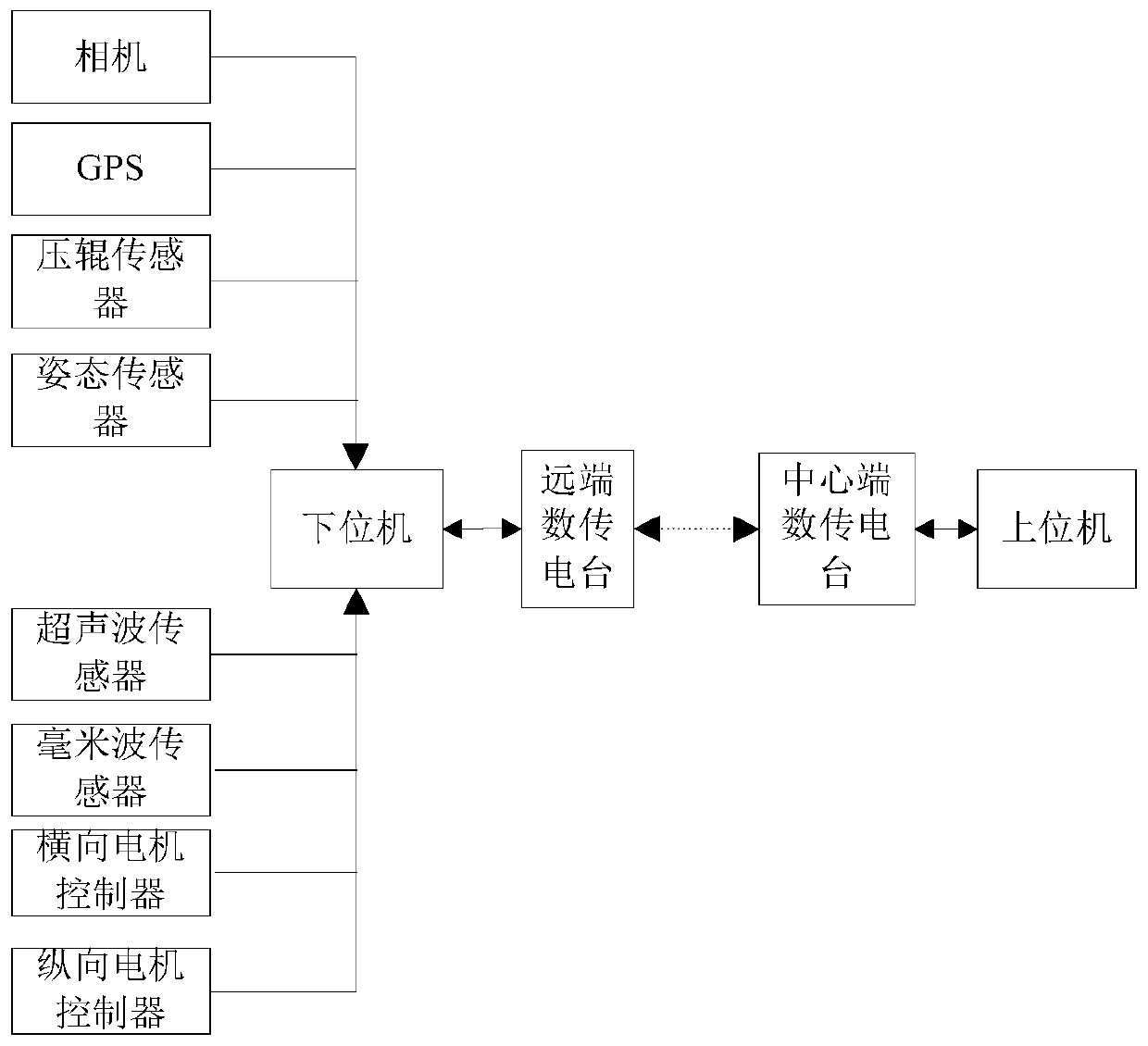

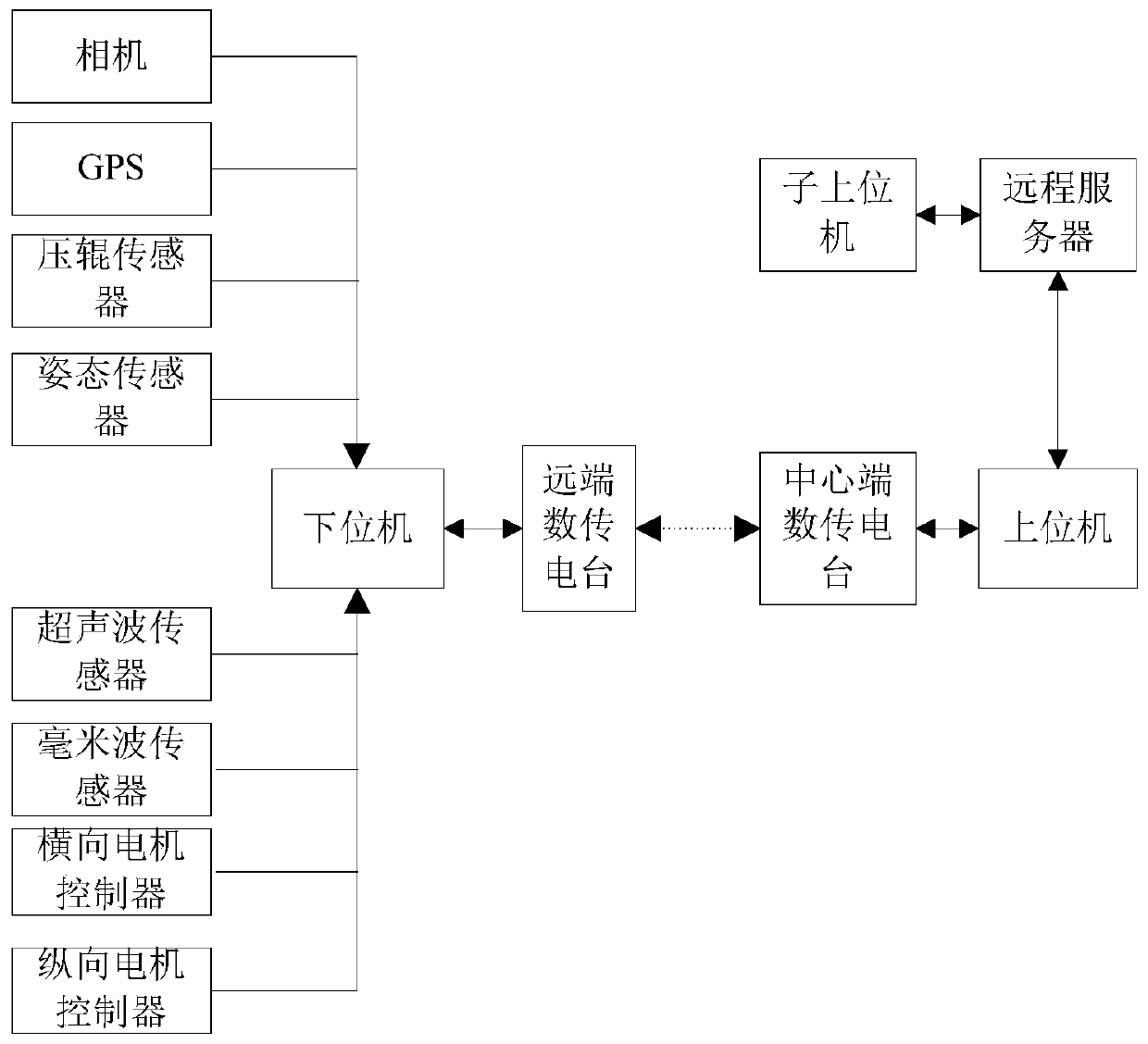

[0038] See attached figure 1 , an unmanned rolling machine cluster intelligent operation remote monitoring and management system, including N rolling machines, each rolling machine is equipped with attitude sensors, GPS, roller sensors, cameras, ultrasonic radar, millimeter wave radar , horizontal motor controller, vertical motor controller, data acquisition control terminal (lower computer) and remote data transmission station.

[0039] The attitude sensor, GPS, pressure roller sensor, camera, ultrasonic radar, millimeter wave radar, horizontal motor controller, vertical motor controller, and remote data transmission station are respectively connected to the data acquisition control terminal, specifically:

[0040] The attitude sensor is used to measure the yaw angle and pitch angle during the operation of the roller compactor, and the obtained attitude information during the operation of the roller compactor is sent to the data acquisition control terminal; two attitude sens...

Embodiment 2

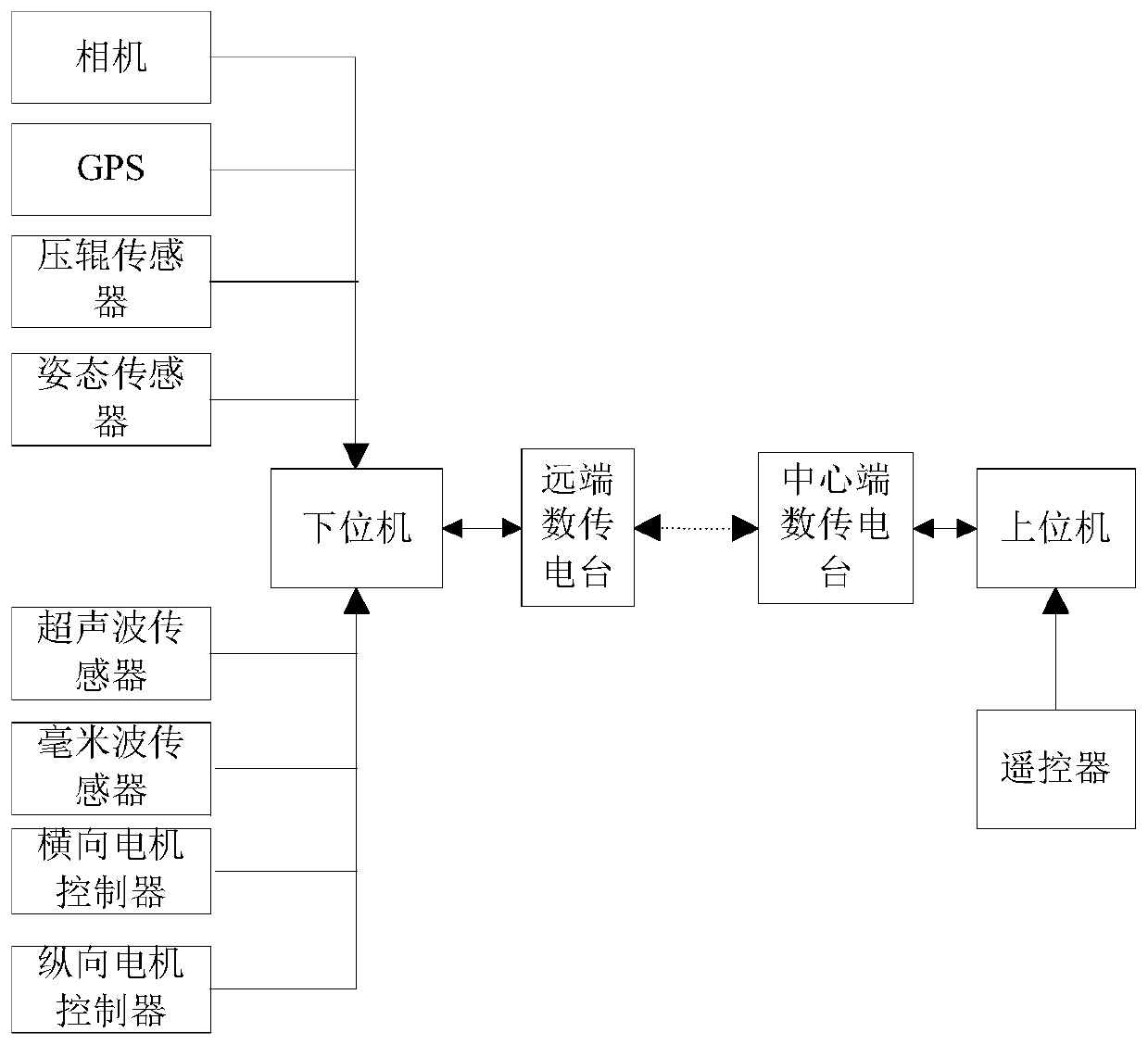

[0054] The remote monitoring and management system for the intelligent operation of the unmanned roller compactor cluster can adopt the manual mode. In the manual mode, the data acquisition control terminal only has the function of collecting data, and does not control the actuators in the car. It needs people to go up and turn on the rolling machine to work.

Embodiment 3

[0056] The remote monitoring and management system for the intelligent operation of the unmanned roller compactor cluster can adopt the remote control mode. In remote control mode, the data acquisition control terminal has the function of collecting data, and the remote monitoring and management platform sends control data to the rolling machine to control the longitudinal motor and horizontal motor of the rolling machine, and then control the rolling machine to move forward, stop, retreat, Turn left, turn right. Furthermore, the data acquisition control terminal of the rolling machine is also connected to multiple execution relays, the execution relays include relays for controlling power-on, relays for controlling ignition, relays for controlling lights, relays for controlling speakers, and relays for controlling the vibration mode. Realize functions such as remote power-on, remote ignition, remote lighting, remote horn, and remote vibration mode switching of the roller comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com