Aqueous organosilicon grafted (methyl) acrylic polymer and preparation method of emulsion thereof

An acrylate and organosilicon technology, applied in the field of polymer materials, can solve the problems of poor placement stability, large hydrolysis group activity, short molecular chain, etc., achieves low requirements for equipment raw materials, realizes industrialized production, and is conducive to industrialized production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

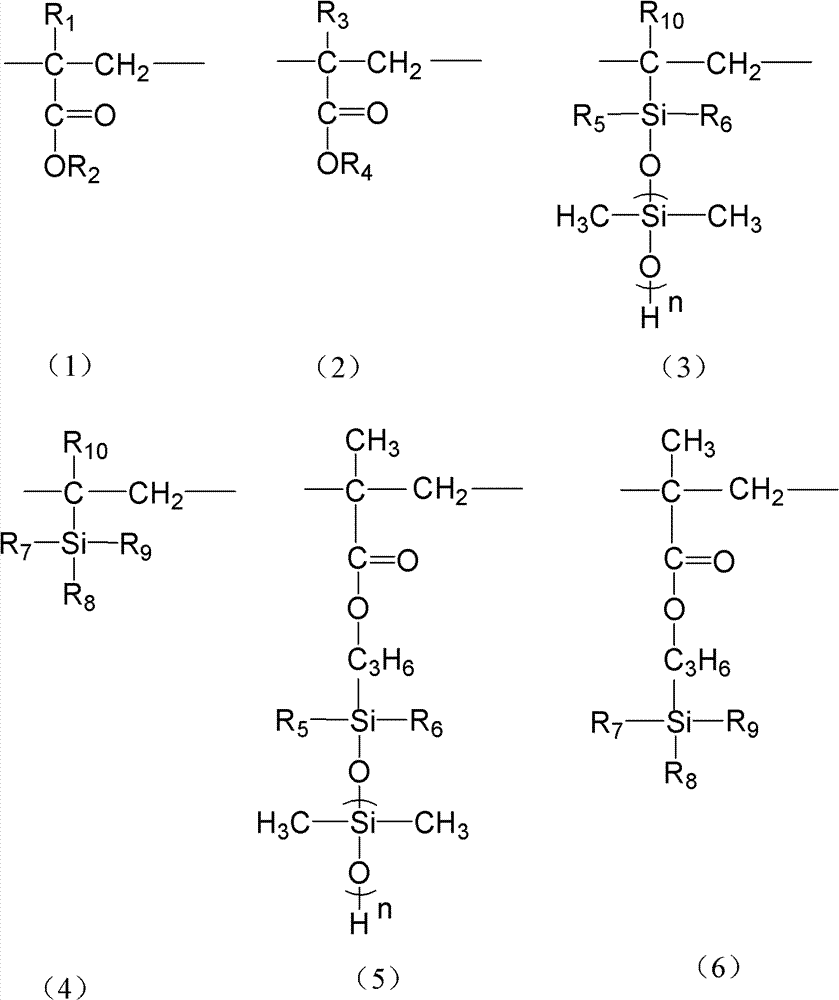

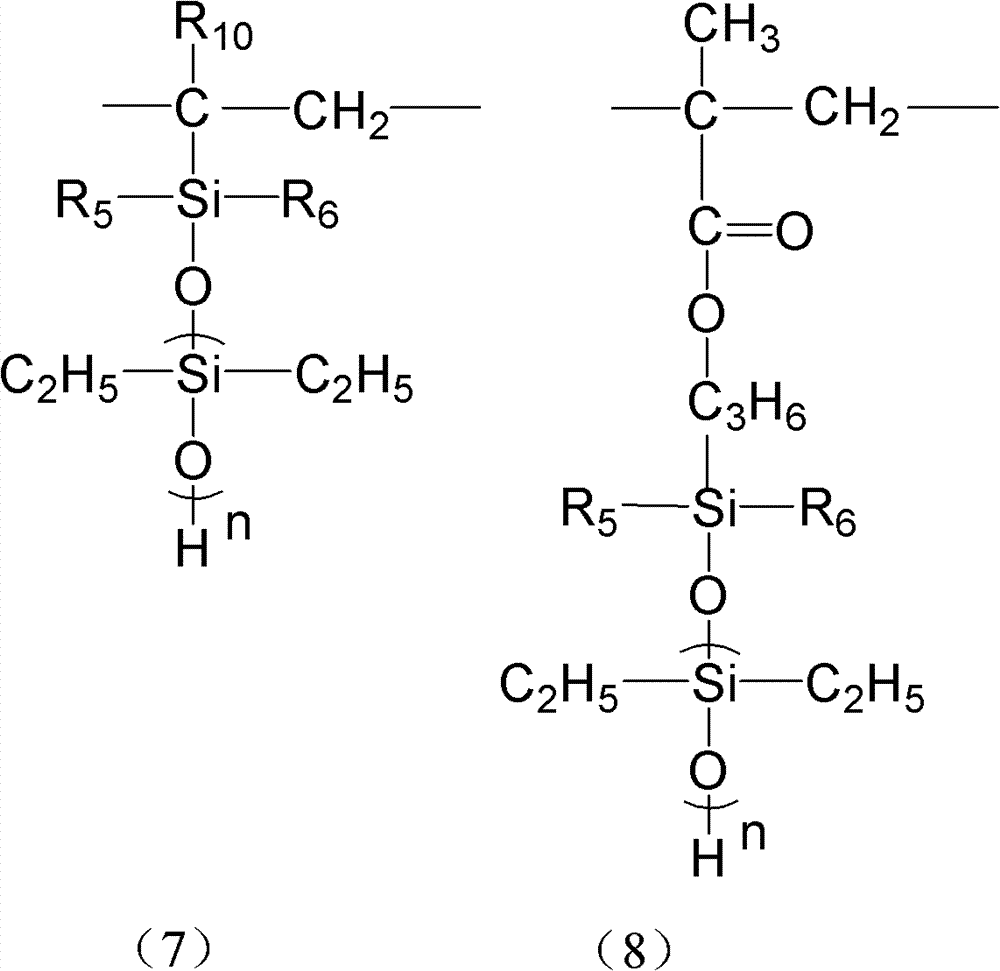

Method used

Image

Examples

Embodiment 1

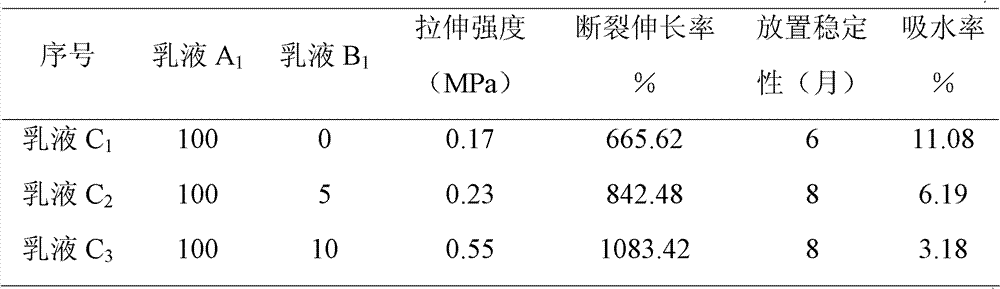

[0040] Table 1 A kind of emulsion of waterborne silicone grafted (meth)acrylate polymer

[0041] Physical properties and coating properties

[0042]

[0043] Among them, emulsion A 1 The synthesis method is: Methyl methacrylate, methyl acrylate, methacrylic acid, γ-methacryloxypropyl trimethoxysilane (KH-570), butanone according to the ratio of 20:25:4:1: 100 feed, initiated by azobisisobutyronitrile (ATBN), control the temperature at 80 ° C, stir and react under reflux for 4 hours, then cool the solution obtained from the reaction to room temperature, add 50 parts of deionized water under stirring to prepare Emulsion A 1 .

[0044] Emulsion B 1 The synthesis method is as follows: feed octamethylcyclo+tetrasiloxane, dodecylbenzenesulfonic acid and deionized water at a ratio of 19:1:40, control the temperature at 75°C, and stir and react under reflux for 1h to obtain Emulsion B 1 .

[0045] Emulsion C 1 Composition of Emulsion A 1 Same.

[0046] Emulsion C 2 with C ...

Embodiment 2

[0054] The emulsion of another kind of aqueous silicone grafted (meth)acrylate polymer of table 2

[0055] Physical properties and coating properties

[0056]

[0057] Among them, emulsion A 2 The synthesis method is: feed butyl methacrylate, butyl acrylate, γ-methacryloxypropyltrimethoxysilane (KH-570) and absolute ethanol at a ratio of 30:18:2:100, and use Water ethanol is used as a solvent, initiated by azobisisobutyronitrile (AIBN), the temperature is controlled at 75°C, the reaction is stirred under reflux for 5.5h, the solution obtained from the reaction is cooled to room temperature, and 50 parts of deionized water to make emulsion A 2 .

[0058] Emulsion B 2 The synthesis method is as follows: feed octamethylcyclotetrasiloxane, hexadecylbenzenesulfonic acid, and deionized water at a ratio of 9:1:20, control the temperature at 70°C, and stir and react under reflux for 1.5h to obtain Emulsion B 2 .

[0059] Emulsion D 1 Composition of Emulsion A 1 Same.

[0...

Embodiment 3

[0068] Table 3 Emulsion of another aqueous silicone grafted (meth)acrylate polymer

[0069] Physical properties and coating properties.

[0070]

[0071] Among them, emulsion A 3 The synthesis method is: (meth)acrylate monomer, γ-methacryloxypropyltrimethoxysilane (KH-570) and methyl ethyl ketone are fed at a ratio of 48:2:100, and diphenyl peroxide Initiated by acyl (BPO), control the temperature at 80°C, stir the reaction under reflux for 4.5h, cool the solution obtained from the reaction to room temperature, add 50 parts of deionized water under stirring to prepare emulsion A 3 . Among the (meth)acrylate monomers, propyl methacrylate is selected as the hard monomer, and butyl acrylate is the soft monomer, and the two are reacted according to the ratio in the table.

[0072] Emulsion B 3 The synthesis method is as follows: feed octamethylcyclotetrasiloxane, dodecylbenzenesulfonic acid, and deionized water at a ratio of 19:1:40, control the temperature at 70°C, and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com