Track damping shock absorber

A shock absorber and damping technology, which is applied in the field of vibration reduction, can solve problems such as waste, rail body 12 and damping shock absorber 11 being scrapped at the same time, and achieve the effects of reducing waste, avoiding economic losses, and ensuring noise reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

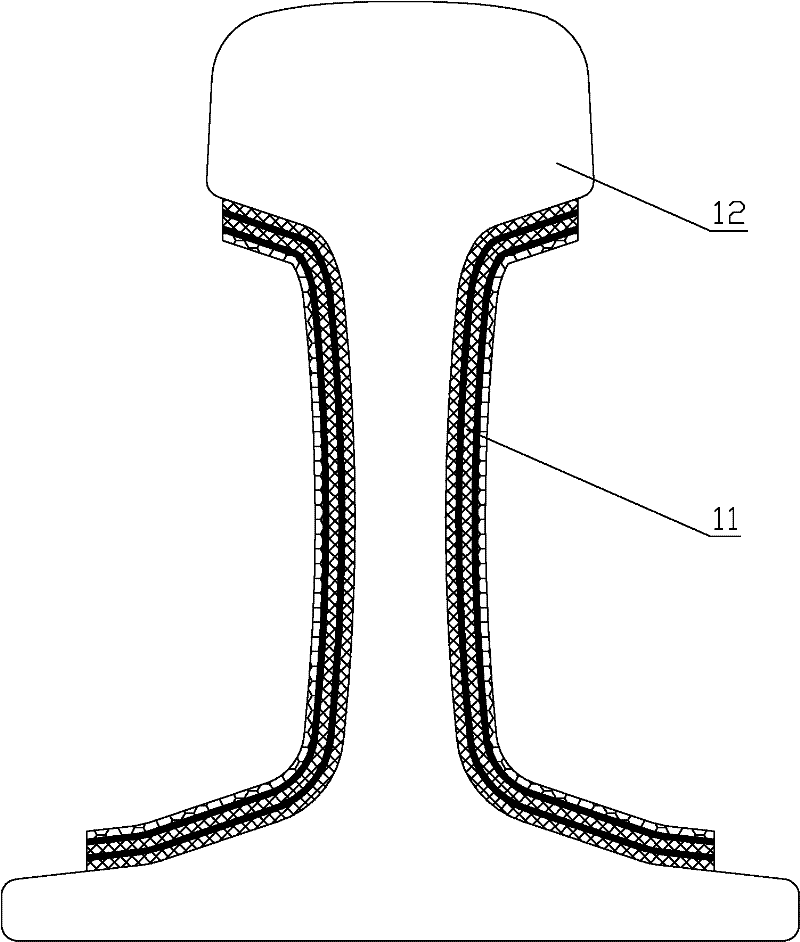

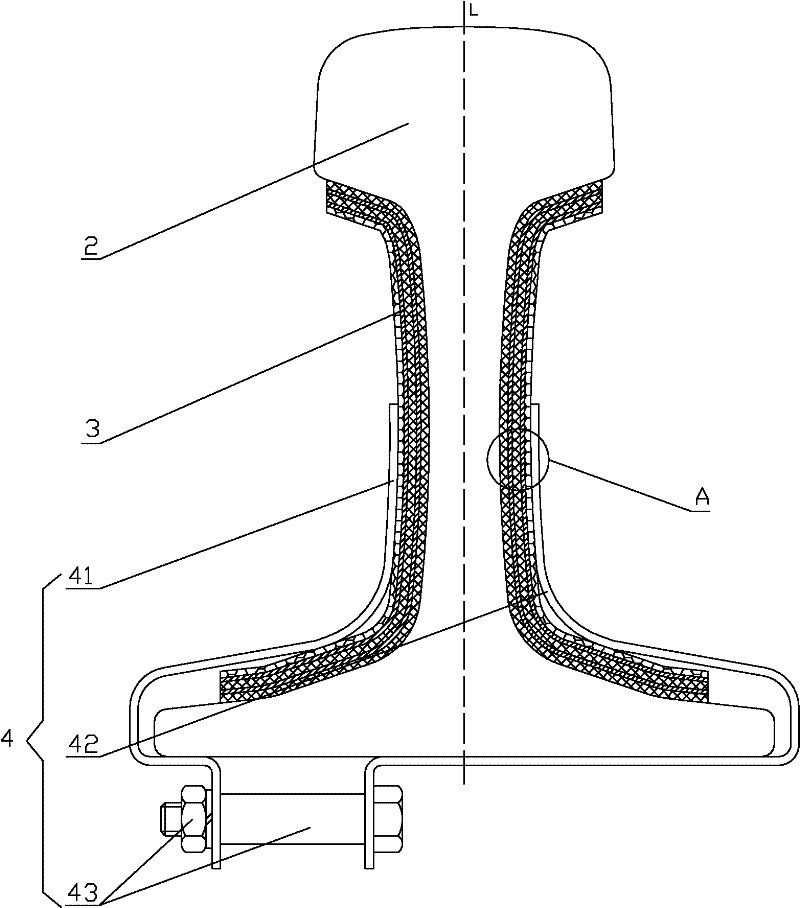

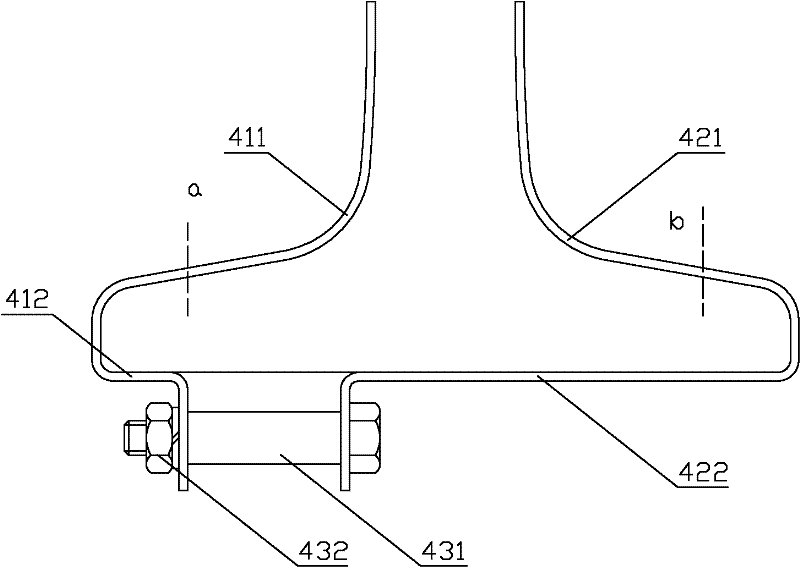

[0024] The core of the present invention is to provide a rail damping shock absorber, which not only has good noise reduction performance, but also is detachably connected with the rail body of the rail, thereby improving the utilization rate of the damping shock absorber and applicability, avoid unnecessary waste, and improve the cost performance of the damping shock absorber.

[0025] The inside and outside involved in this article are defined based on the rail body of the rail, the inside is close to the outer surface of the rail, and the outside is far away from the outer surface of the rail; the left and right involved in this article are based on figure 2 The center line L of the track section shown is defined by the datum. It should be understood that the orientation words used herein shall not limit the protection scope of this patent.

[0026] In order to enable those skilled in the art to better understand the solution of the present invention, the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com