Mainstay Turbocharger Electronically Controlled Pressure Relief Valve

A technology for turbochargers and pressure relief valves, applied in valve details, valve devices, machines/engines, etc., can solve problems such as prone to surge, easy to generate airflow noise, and reduced speed-up performance and comfort, so as to avoid Effects of supercharger surge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

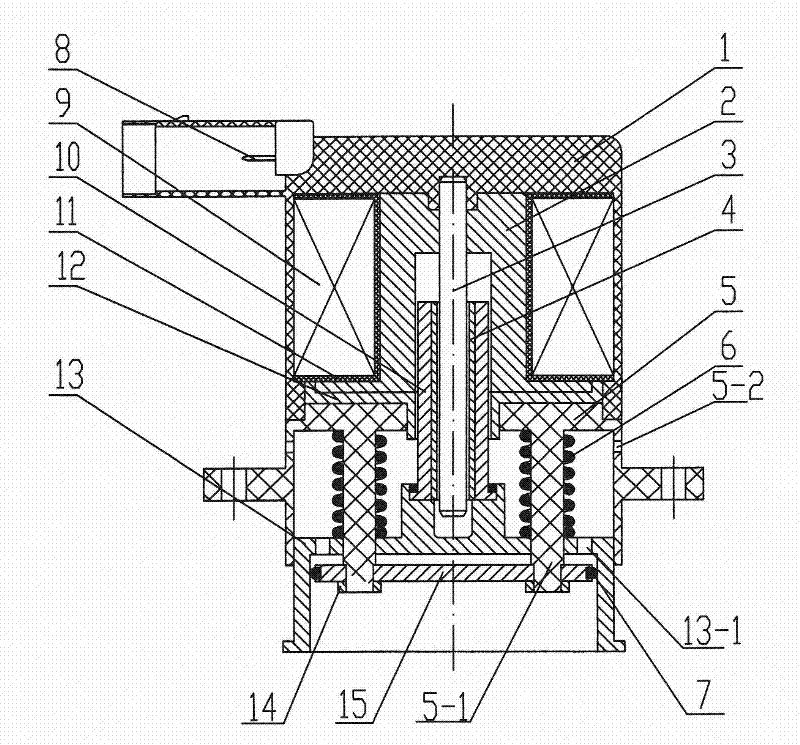

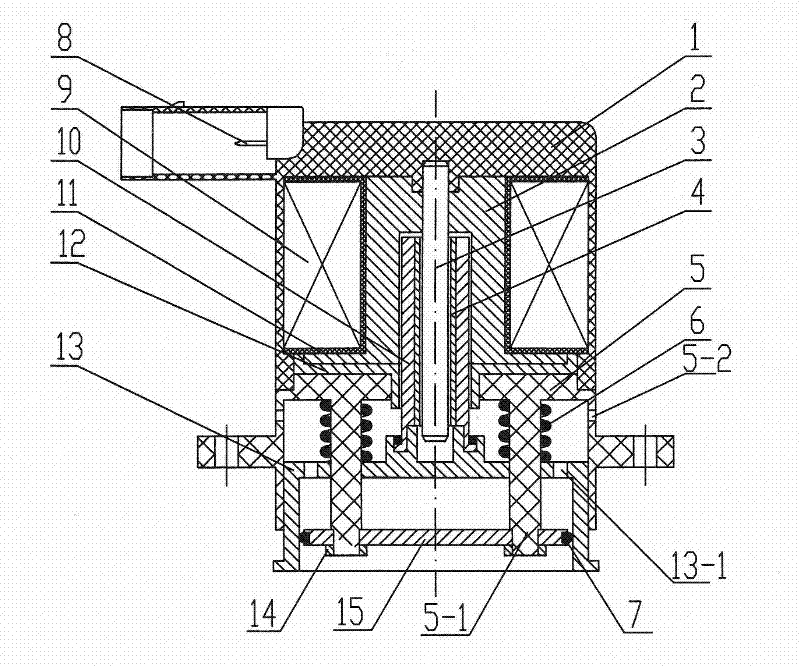

[0022] A mainstay type turbocharger electronically controlled pressure relief valve, which consists of an upper casing 1 with an electronically controlled socket 8, a guide seat 2, a static iron core 3, a moving iron core inner shaft sleeve 4, and a lower casing 5 , spring 6, sealing ring 7, coil winding frame 11 with coil winding 9, moving iron core 10, moving iron core outer shaft sleeve 12, piston sleeve 13, nut 14, baffle plate 15 are formed.

[0023] The outer shaft sleeve 12 of the moving iron core, the coil winding frame 11 with the coil winding 9, and the guide seat 2 are inlaid in the upper casing 1 by injection molding; the piston sleeve 13 is inlaid on the moving iron core 10 by injection molding, and the inner shaft of the moving iron core The sleeve 4 is press-fitted in the shaft hole of the moving iron core 10; the upper shell 1 is set on the lower shell 5, and is connected with the lower shell 5 to form an interference fit; the static iron core 3 is a round bar, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com