Method and apparatus for producing container-shaped composite packaging

A composite packaging and equipment technology, used in containers, packaging, transportation and packaging, etc., can solve problems such as inability to meet, and achieve the effect of improving production speed, high quality and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

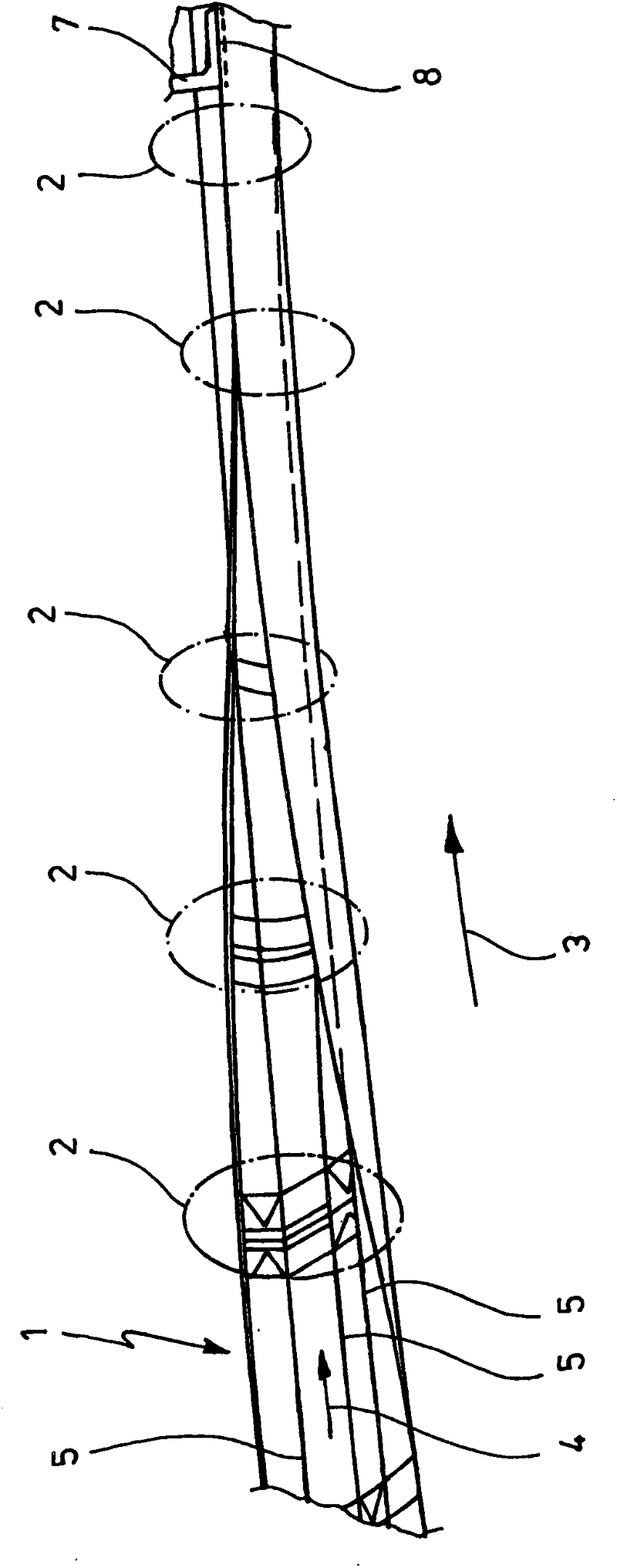

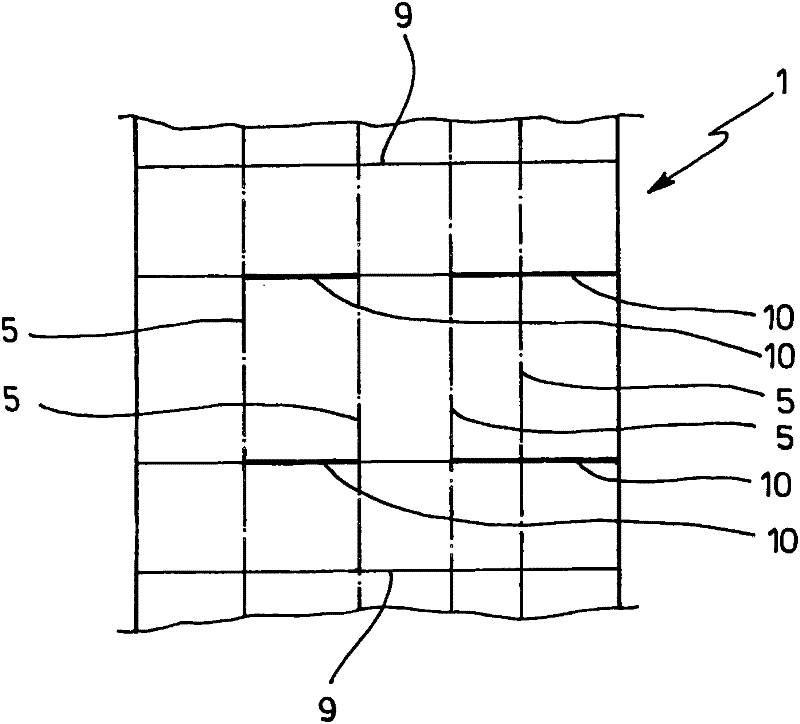

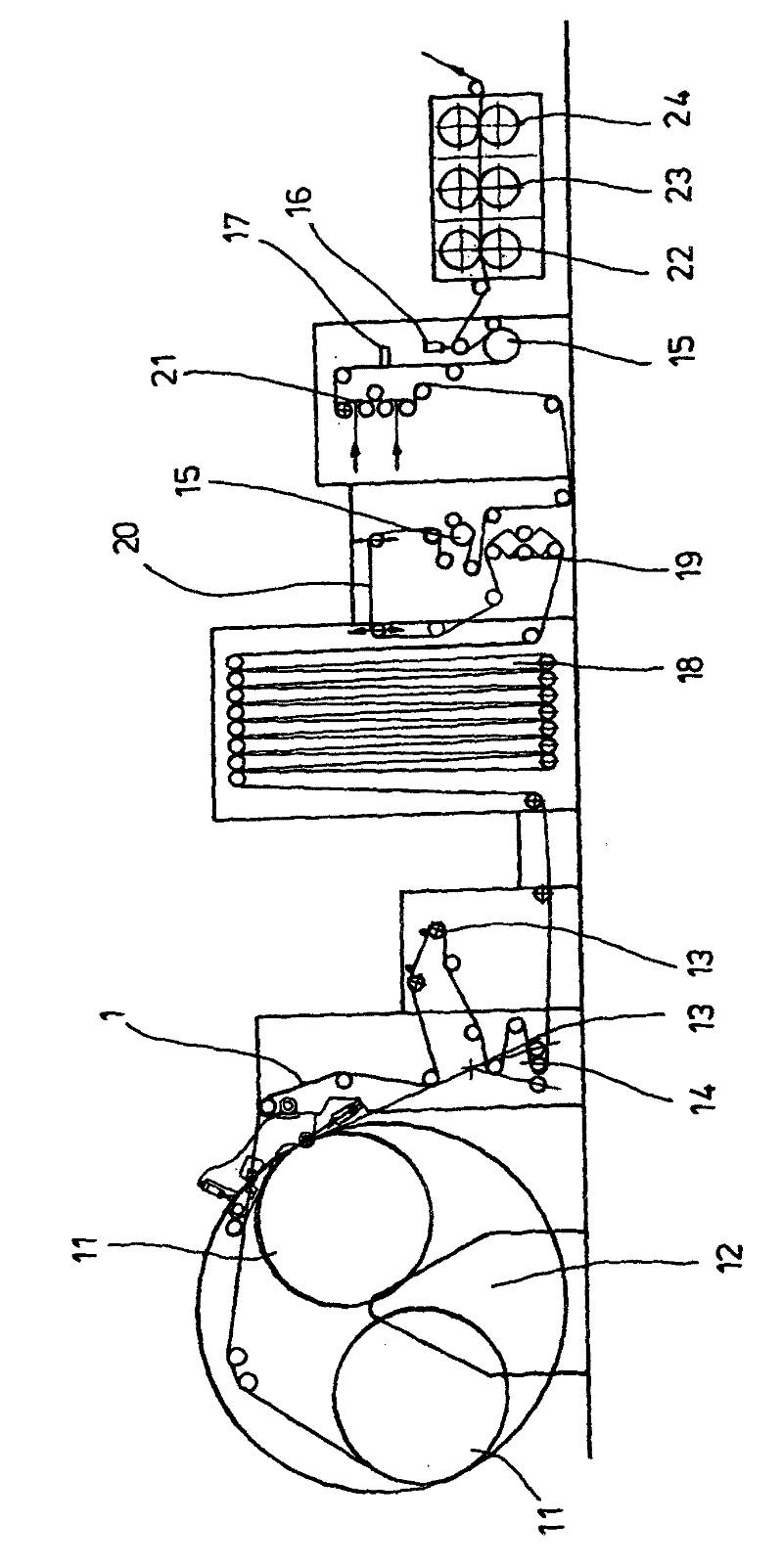

[0039] figure 1 is a schematic diagram for illustrating the basic principles of the present invention. The web-like material 1 is moved along the guide elements 2 in the conveying direction 3 . The conveying direction 3 corresponds here to the longitudinal direction 4 of the web-shaped material 1 . The web-shaped material 1 has a linear material weakening 5 in the longitudinal direction 4 . The material weakening 5 can be produced, for example, by groove lines, material removal, perforation or thermal loading. For the production of square containers, four linear material weakenings 5 are typically produced in order to support the folding process of the web-shaped material 1 in the region of said material weakenings 5 and to precisely predetermine the positioning of the folding lines. . In the case of other cross-sectional geometries, more or fewer folding lines can also be used.

[0040] The task of the guide element 2 is to predetermine and carry out the folding proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com