Dynamic Probe Detection System

A detection system, probe technology, used in the field of probe microscopy to solve problems such as accuracy or speed limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

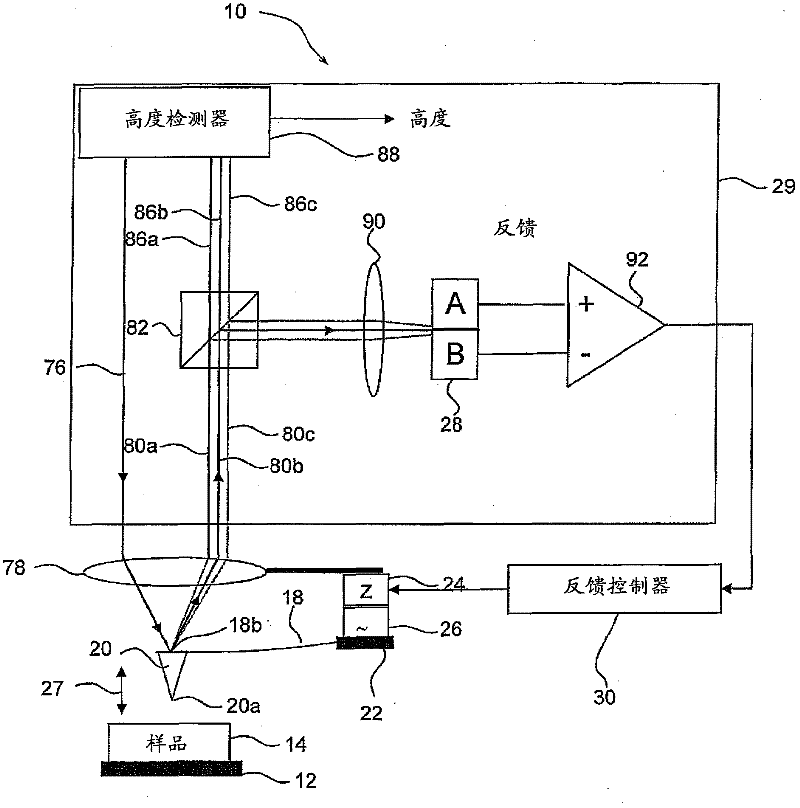

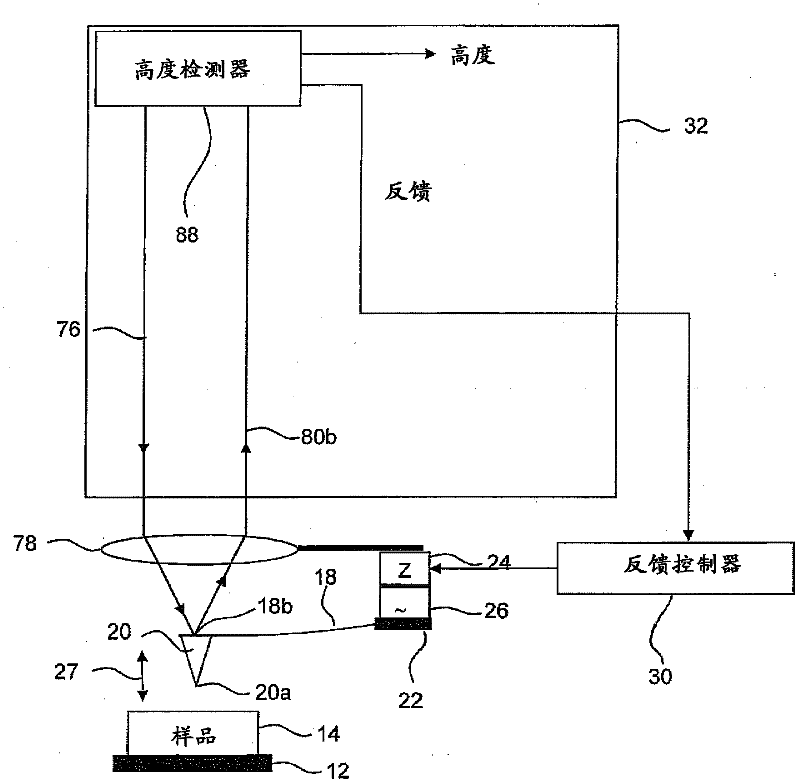

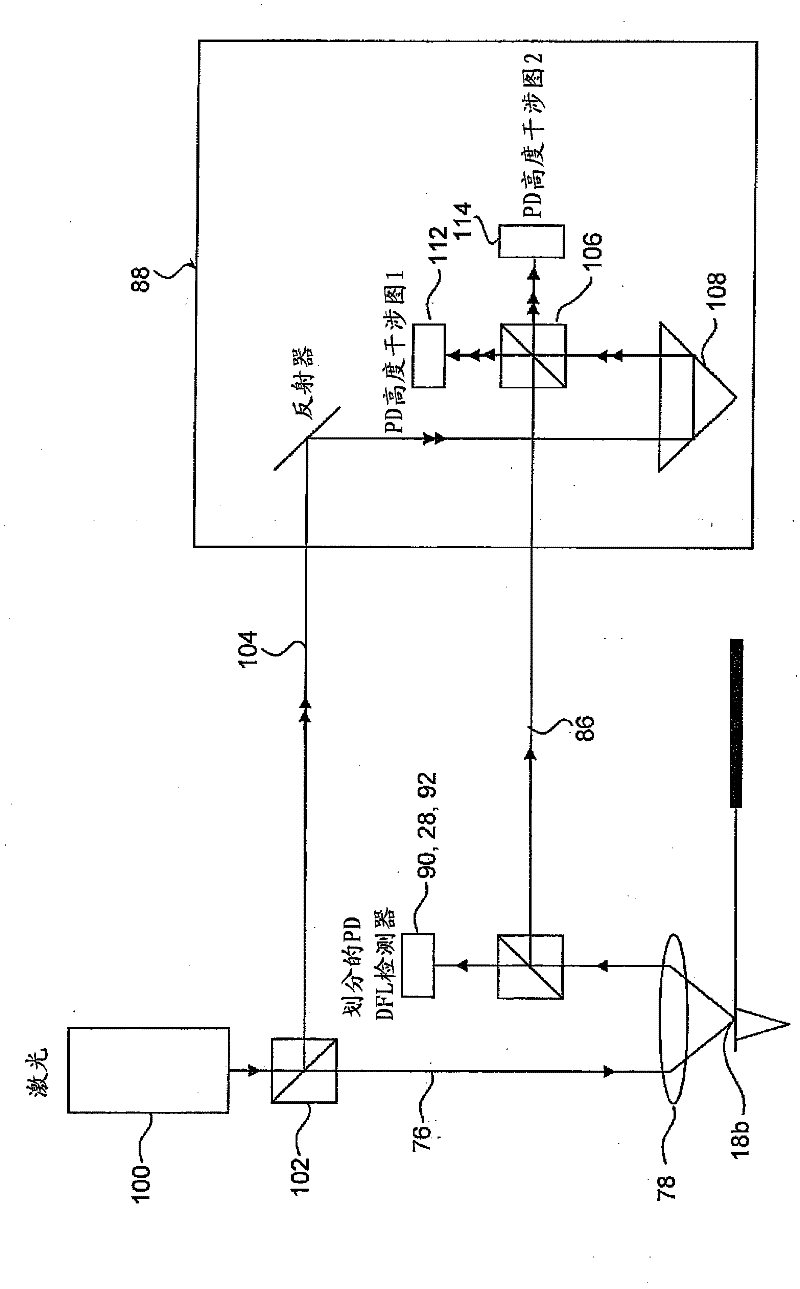

[0062] refer to figure 1 , schematically shows a modified implementation of an AFM generally indicated at 10 according to the invention. The AFM apparatus shown includes a movable platform 12 adapted to receive a sample 14 whose surface is to be viewed by a probe 16 . The probe 16 includes a cantilever beam 18 and a tip 20 that tapers to a point 20 a and is positioned toward one end of the cantilever beam 18 . The other end of the cantilever beam 18 is supported by a base plate 22 .

[0063] One or more drive motors (24, not shown) are used to drive sample 14 (together with stage 12) and / or probe 16 so that they can scan x, y and z directions relative to each other in three dimensions as described below. As is conventional in the art, the z-axis of the Cartesian coordinate system is taken to be the axis perpendicular to the plane occupied by the sample 14 . That is, the strength of the interaction force between the probe 16 and the sample 14 depends both on the xy position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com