Sweet Potato Washing Machine

A technology of potato cleaning machine and potato, which is applied in application, food processing, climate change adaptation, etc. It can solve the problems of difficult cleaning, waste of water resources, difficulty in cleaning potato and potato accumulation, etc., and achieve good cleaning quality and high cleaning efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

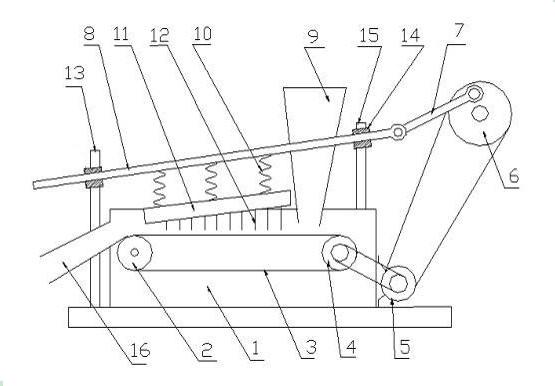

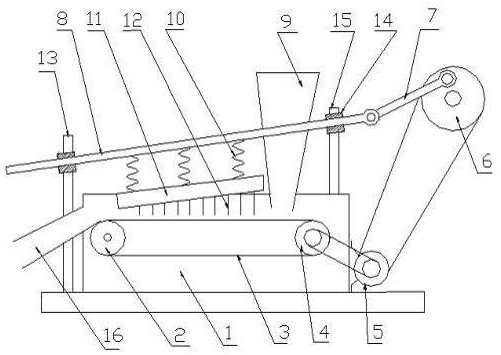

[0009] In the figure, the sweet potato washing machine includes a sink 1, a driven wheel 2, a conveyor belt 3, a driving wheel 4, a motor 5, an eccentric wheel 6, a connecting rod 7, a transmission rod 8, a hopper 9, a spring 10, a washboard 11, and bristles 12 , short support 13, sliding bearing 14, high support 15, discharge opening 16, a driving wheel 4 and a driven wheel 2 are provided in the described pool 1, and a conveyor belt 3 is installed between the driving wheel 4 and the driven wheel 2. A motor 5 is installed on the outside of the pool 1, and the motor 5 drives the driving wheel 4 through a belt. On both sides of the upper mouth of the pool 1, a short bracket 13 and a high bracket 15 are fixedly installed respectively, and on the top of the high bracket 15 and the short bracket 13 Sliding bearings 14 are fixedly installed respectively. Between the sliding bearings 14, a sliding transmission rod 8 is fixedly installed. The transmission rod 8 forms an inclination an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com