Method for producing pearl powder by porcelain ball rolling and water milling

一种珍珠粉、水磨法的技术,应用在医药配方、含有效成分的医用配制品、谷物处理等方向,能够解决降低珍珠粉药效、降低珍珠粉天然性等问题,达到保证药用价值、保证纯天然性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

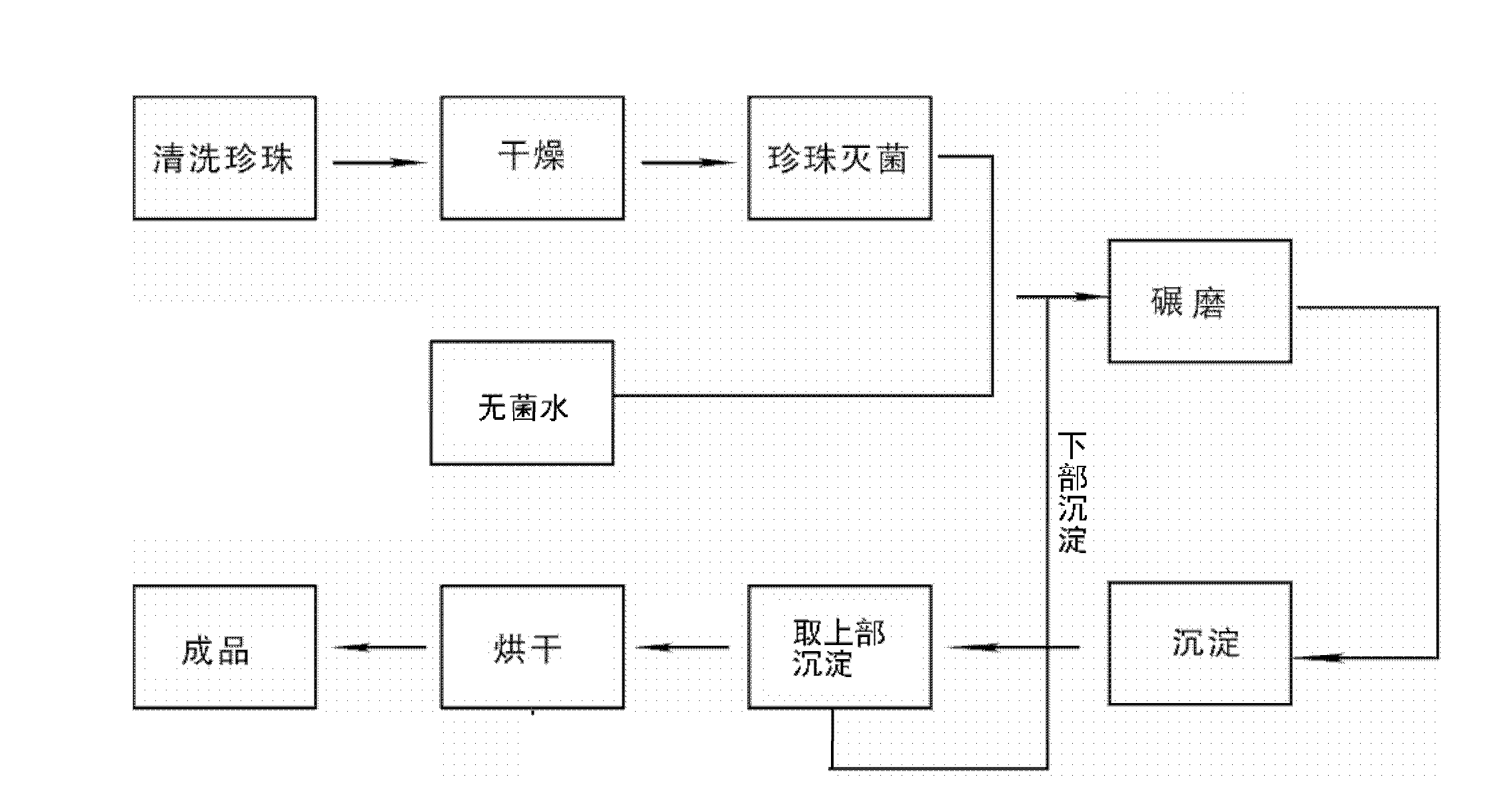

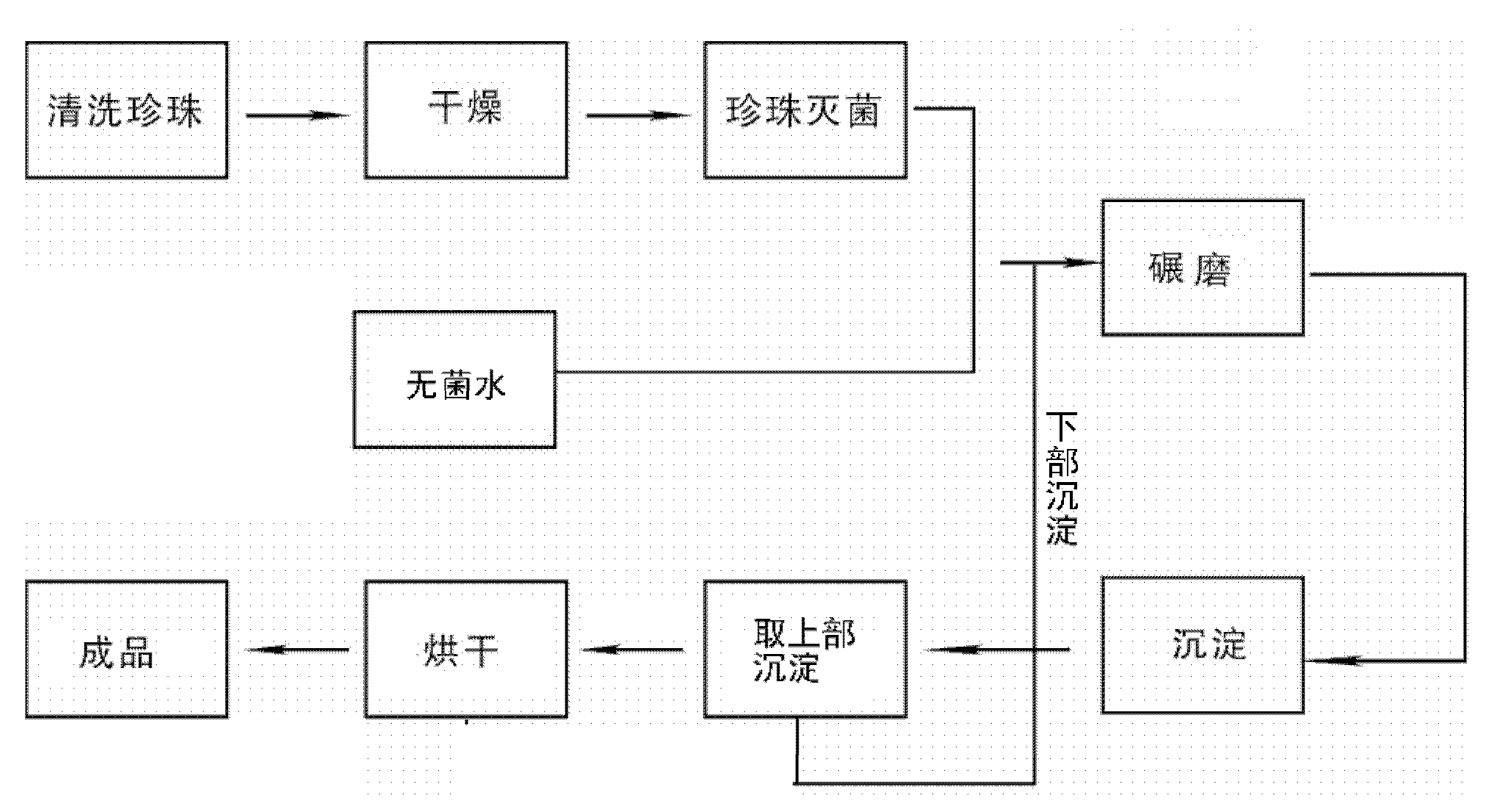

Method used

Image

Examples

Embodiment 1

[0017] Embodiment one: a kind of method that porcelain ball rolling water milling method produces pearl powder, comprises the following processing steps:

[0018] (1) Material selection: choose 3-year-old pearls with a diameter of 3.5mm, and remove flat pearls, stone pearls, and diseased pearls;

[0019] (2) Cleaning pearls: Put the pearls and clear water into the first cleaning porcelain vat according to the mass ratio of 1:1, rotate the first cleaning porcelain vat to clean, the rotation speed of the first cleaning porcelain vat is 40 rpm, and the cleaning time For 5 minutes, the temperature of the clear water is 40°C; take out the pearls and put them into the second cleaning porcelain vat, add cleaning agent, turn the second cleaning porcelain vat to clean, the mass ratio of pearls to cleaning agent is 100:1, and the second cleaning The rotation speed of the porcelain vat is 40 rpm, and the cleaning time is 5 minutes; the pearls are taken out, put into the third cleaning va...

Embodiment 2

[0024] Embodiment two: a kind of porcelain ball rolling water milling method produces the method for pearl powder, comprises the following processing steps:

[0025] (1) Material selection: choose 4-year-old pearls with a diameter of 4.2mm, and remove deflated, stone and diseased pearls;

[0026] (2) Cleaning pearls: put the pearls and clear water into the first cleaning porcelain vat according to the mass ratio of 1.1: 1.1, and rotate the first cleaning porcelain vat for cleaning. 5.1 minutes, the water temperature is 42 ℃; take out the pearls and put them into the second cleaning porcelain vat, add cleaning agent, turn the second cleaning porcelain vat to clean, the mass ratio of pearls to cleaning agent is 102:1, the second cleaning The rotation speed of the porcelain vat is 42 rpm, and the cleaning time is 5.1 minutes; take out the pearls, put them into the third cleaning vat, add pure water, turn the third cleaning vat to clean, the mass ratio of the pearls to the pure wa...

Embodiment 3

[0031] Embodiment three: a kind of method that porcelain ball rolling water milling method produces pearl powder, comprises following processing steps:

[0032] (1) Material selection: choose 5-year-old pearls with a diameter of 5mm, and remove flat pearls, stone pearls, and diseased pearls;

[0033] (2) Cleaning pearls: Put the pearls and clear water into the first cleaning porcelain vat according to the mass ratio of 1:1, turn the first cleaning porcelain vat to clean, the rotation speed of the first cleaning porcelain vat is 41 rpm, and the cleaning time For 5 minutes, the temperature of the clear water is 41°C; take out the pearls and put them into the second cleaning porcelain vat, add cleaning agent, turn the second cleaning porcelain vat to clean, the mass ratio of pearls to cleaning agent is 101, and the second cleaning porcelain vat The rotating speed is 41 rpm, and the cleaning time is 5 minutes; take out the pearls, put them into the third cleaning porcelain vat, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com