Herbal concentrated solution production process

A production process and concentrate technology, applied in the field of herbal extract product production, can solve the problems of reducing the quality of the extract, loss of flavor, and insufficient removal of harmful substances such as pesticide residues, so as to prevent the existence of harmful substances to the human body, prevent Oxidation and dissipation to ensure the effect of pure naturalness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

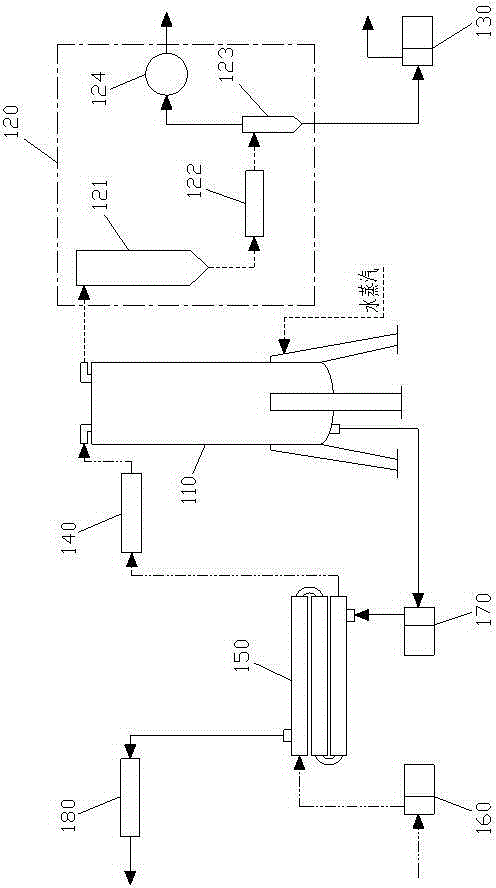

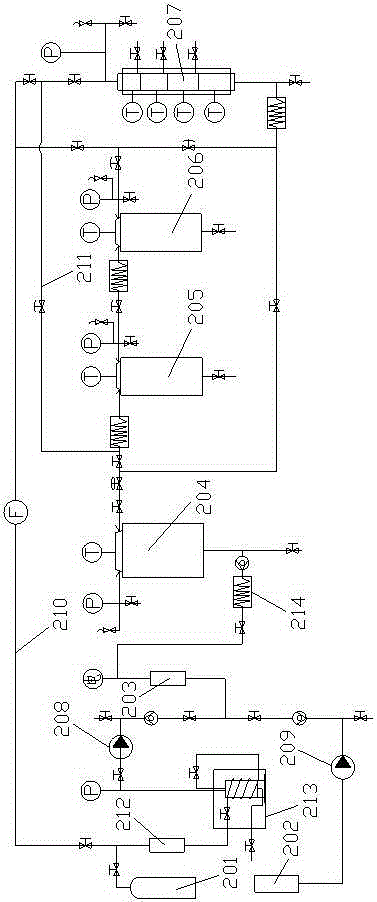

[0036] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

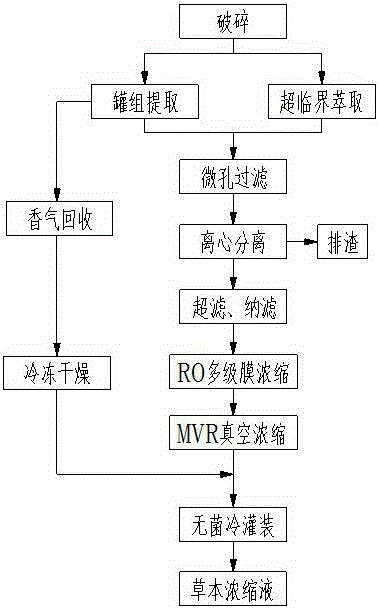

[0037] like figure 1 Shown, a kind of herbal concentrate production process comprises the following steps:

[0038] (1) Crushing: The existing low-temperature wall-breaking crusher is used for physical low-temperature crushing of herbal cells, and the full physical low-temperature wall-breaking extraction technology can solve the problems of high-temperature extraction destroying herbal active ingredients and low-temperature extraction efficiency;

[0039] (2) Multifunctional extraction: extract the crushed herbs in step (1) by combining tank group extraction and supercritical extraction to obtain herbal extracts; the tank group extraction performs aroma recovery during extraction to capture the herb in the spraying process Volatile aroma substances lost due t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com