Supercritical CO2 extraction process of onion oil

An extraction process, a technology for onion oil, applied in the fields of edible oil/fat, food science, application, etc., can solve the problems of excessive destruction of active substances, poor quality of onion oil, low extraction rate, etc., to achieve high product quality, energy saving, High extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

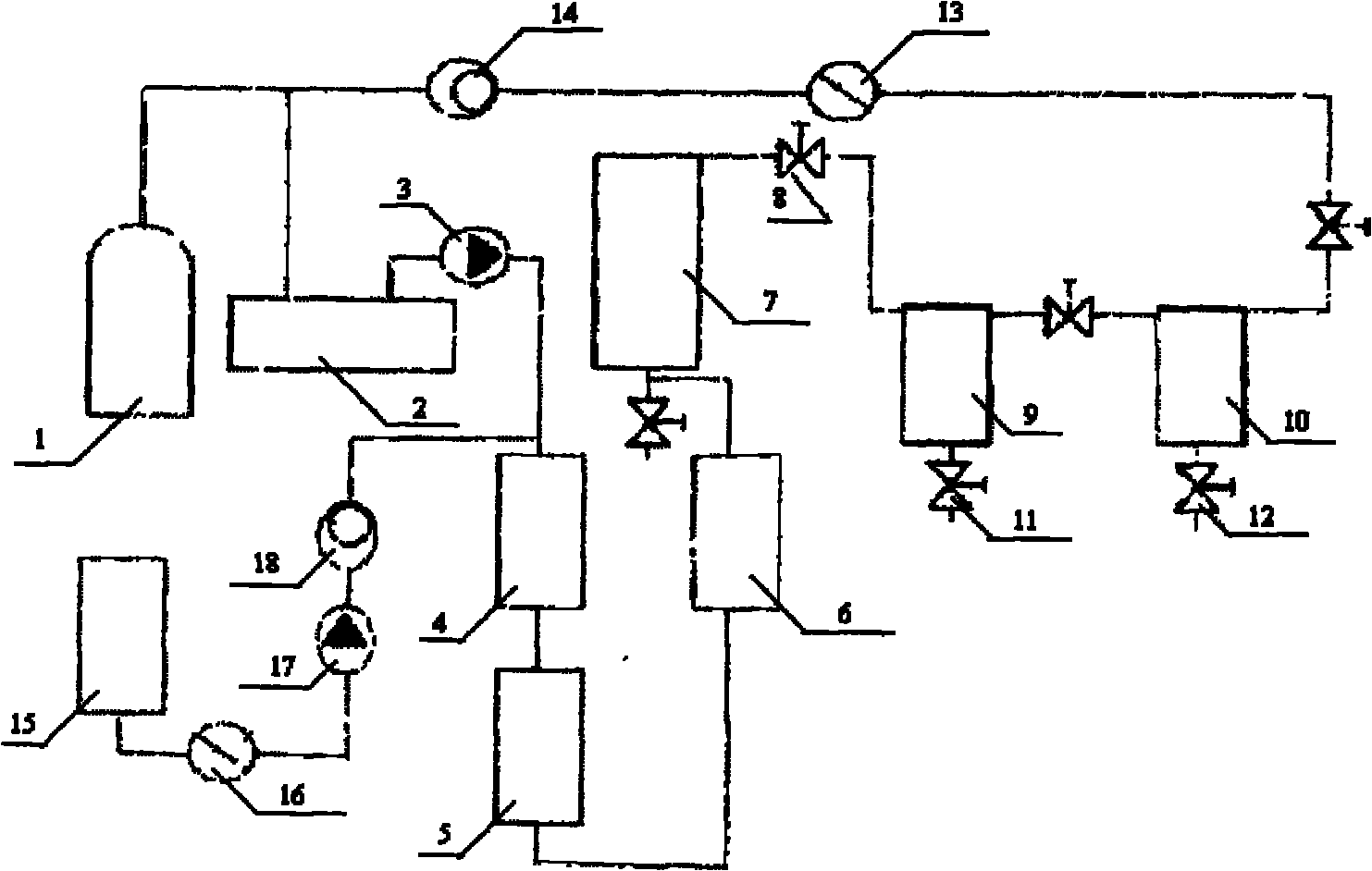

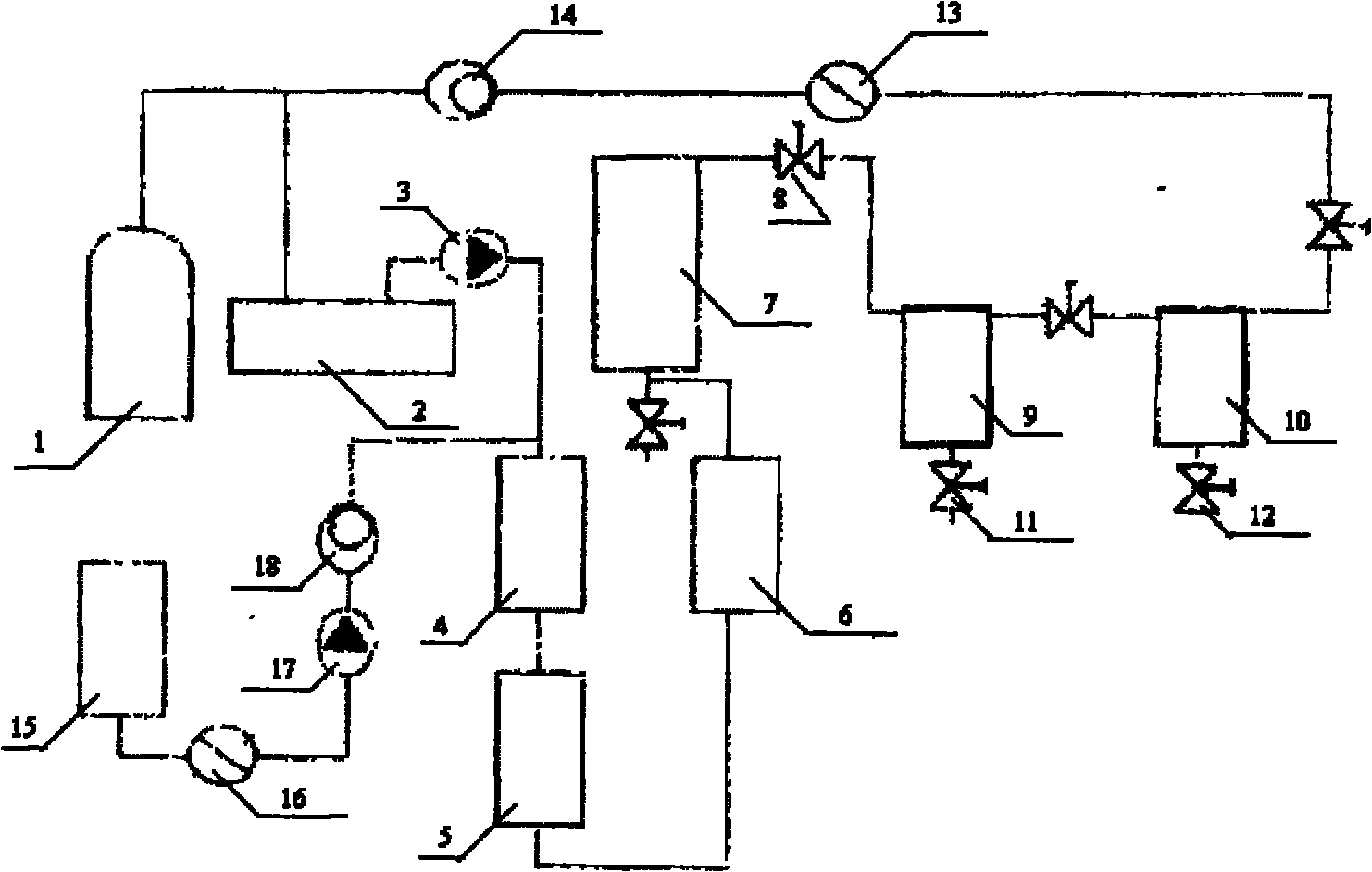

Method used

Image

Examples

Embodiment 1

[0018] Weigh 80g of freeze-dried onion powder and put it into HA231-50-06 supercritical CO 2 Fluid extraction device (manufactured by Huaan Supercritical Extraction Company, Nantong City, Jiangsu Province), adjust the extraction pressure to 20Mpa, the extraction temperature to 40°C, add entrainer anhydrous ethanol 0.15mL / g, CO 2 The flow rate is 22L / h, the extraction time is 4h, the separation pressure I is 8MPa, and the temperature is 40°C; the separation pressure II is 6MPa, and the temperature is 35°C. The extract is collected at the outlet of the extraction kettle to obtain crude onion oil. The crude product was extracted three times with dichloromethane at a volume ratio of 1:1 at 25° C., recovered at 42° C., and the remaining water was removed with anhydrous sodium sulfate to obtain 0.392 g of refined onion oil.

Embodiment 2

[0020] Weigh 60g of freeze-dried onion powder and put it into HA231-50-06 supercritical CO 2 Fluid extraction device (manufactured by Huaan Supercritical Extraction Company, Nantong City, Jiangsu Province), adjust the extraction pressure to 20Mpa, extract the temperature to 45°C, add entrainer anhydrous ethanol 0.10mL / g, CO 2 The flow rate is 22L / h, the extraction time is 3h, the separation pressure I is 8MPa, and the temperature is 40°C; the separation pressure II is 6MPa, and the temperature is 35°C. The extract is collected at the outlet of the extraction kettle to obtain crude onion oil. The crude product was extracted three times with dichloromethane at a volume ratio of 1:1 at 25°C. The dichloromethane was recovered at 42°C, and the remaining water was removed with anhydrous sodium sulfate to obtain 0.228 g of refined onion oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com