Frame high-altitude piece mounting method of dry quenching lifter device

A technology for installing a frame and an installation method, which is used in coke ovens, cranes, coke cooling, etc., can solve the problems of not arriving on time, high entry costs, affecting construction periods, etc. cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

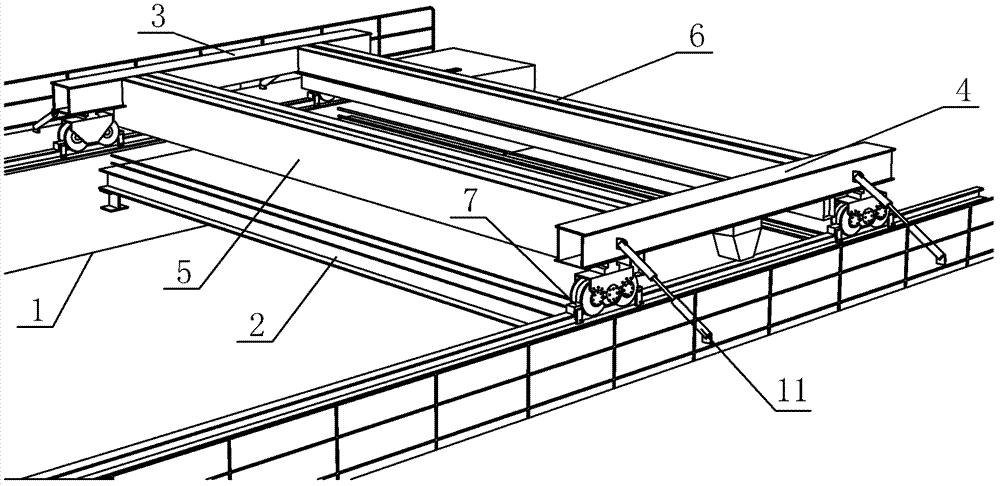

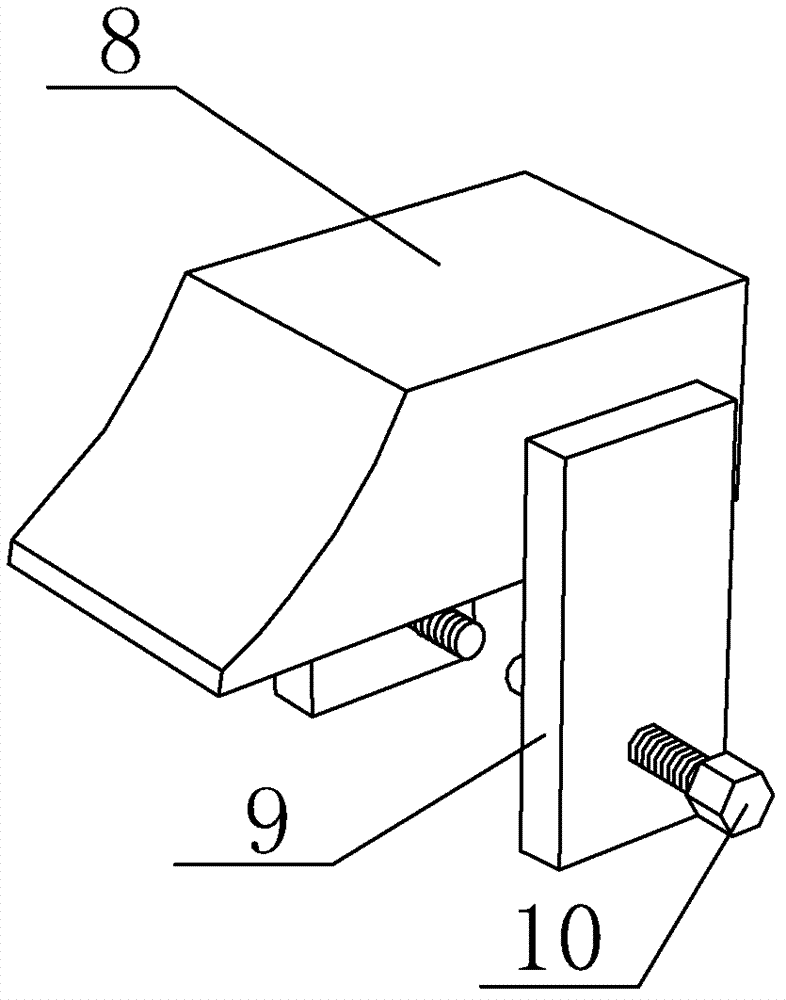

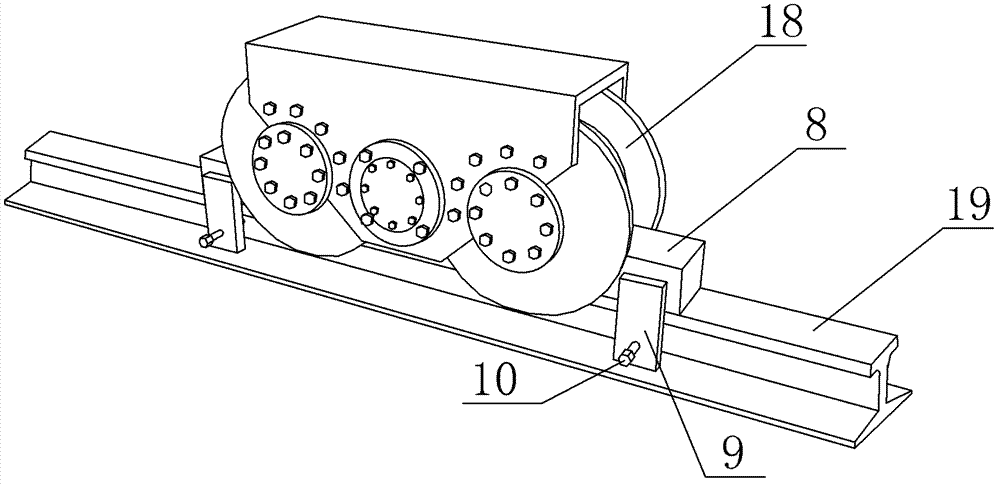

[0030] The high-altitude fragmentation installation method for the frame of the CDQ hoist device provided by the present invention is specifically: using a ≤300-ton automobile crane to hoist the end beams of the frame fragmentation parts to the hoist track, and then lift the frame fragmentation parts The main girder is hoisted to the middle of the beams at both ends and assembled. The assembly process is carried out on the high-altitude construction platform, so that the original frame assembly work on the ground is changed to be completed at high altitude; in the process of assembling the frame on the high-altitude construction platform, first Use the adjustable end beam fixing device to adjust the distance between the two ends of the beam, and then use the wheel fixing device to accurately position and install the two ends of the beam on the hoist track, so that the error of the diagonal length of the two ends of the beam does not exceed 3mm. The main beam is connected with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com