Preparation method of high-specific surface area mangosteen shell active carbon rich in mesopores

A technology with high specific surface area and mangosteen shell, which is used in the removal of solid waste and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

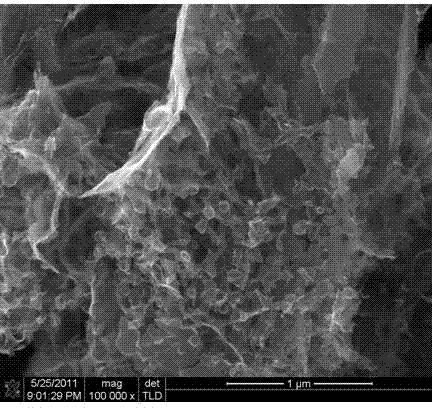

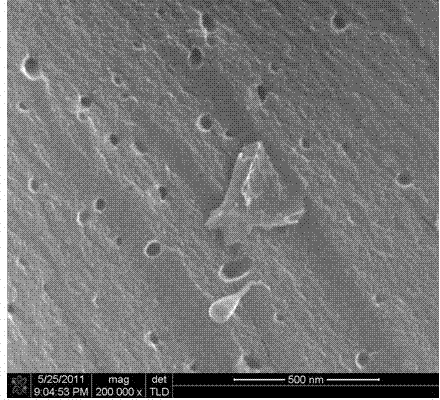

Image

Examples

Embodiment 1

[0018] (1) Wash the discarded mangosteen shells, dry them naturally, crush them, pass through a 40-mesh sieve, and dry them at 105°C for 12 hours to constant weight, then seal them in sealed bags and place them in a desiccator for later use.

[0019] (2) Mix and impregnate the mangosteen shell powder described in step (1) and the potassium oxalate solution with a mass fraction of 20% at a mass ratio of 1:0.5, mix and impregnate with the potassium oxalate solution for 12 hours, then dry at 105°C for 12 hours to obtain a mixed Put the mixed material in a muffle furnace, raise the temperature to 700 °C at a rate of 8 °C / min, keep it warm for 2 hours, and cool naturally to obtain a carbonized sample.

[0020] (3) The carbonized sample described in step (2) was acid-washed with 10% HCl solution for 30 minutes, the temperature was controlled at 70°C, and then washed with deionized water until the pH value was neutral, and dried at 105°C for 12 hours. That is, the mangosteen shell ac...

Embodiment 2

[0022] (1) Wash the discarded mangosteen shells, dry them naturally, crush them, pass through a 40-mesh sieve, and dry them at 110°C for 24 hours to constant weight, then seal them in sealed bags and place them in a desiccator for later use.

[0023] (2) Mix and impregnate the mangosteen husk powder described in step (1) with the potassium oxalate solution with a mass fraction of 30% in a mass ratio of 1:2 and impregnate with the potassium oxalate solution for 24 hours, then dry at 110°C for 24 hours to obtain a mixed Put the mixed material in a muffle furnace, raise the temperature to 900 °C at a rate of 12 °C / min, keep it warm for 1 h, and cool naturally to obtain a carbonized sample.

[0024] (3) The carbonized sample described in step (2) was acid-washed with 15% HCl solution for 45 min, the temperature was controlled at 90 °C, and then washed with deionized water until the pH value was neutral, and dried at 110 °C for 24 h , that is, a mangosteen shell activated carbon wi...

Embodiment 3

[0026] (1) Wash the discarded mangosteen shells, dry them naturally, crush them, pass through a 40-mesh sieve, and dry them at 108°C for 18 hours to constant weight, then seal them in sealed bags and place them in a desiccator for later use.

[0027] (2) Mix and impregnate the mangosteen shell powder described in step (1) and the potassium oxalate solution with a mass fraction of 20-30% at a mass ratio of 1:1.2, and then mix and impregnate with the potassium oxalate solution for 18 hours, then dry at 108°C for 18 hours To obtain the mixture, put the mixture in a muffle furnace, raise the temperature to 800°C at a rate of 10°C / min, keep it warm for 2 hours, and cool naturally to obtain a charred sample.

[0028] (3) The carbonized sample described in step (2) was acid-washed with 12% HCl solution for 37 min, the temperature was controlled at 80 °C, and then washed with deionized water until the pH value was neutral, and dried at 108 °C for 18 h , that is, a mangosteen shell act...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| adsorption value of blue | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com