Treatment method of high-concentration organic process wastewater of amprolium hydrochloride

Amprolium hydrochloride, high-concentration technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, organic chemistry, etc., can solve problems such as high treatment cost, poor biodegradability, and damage to environmental quality , to achieve the effect of reducing pollution load, high elution efficiency and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

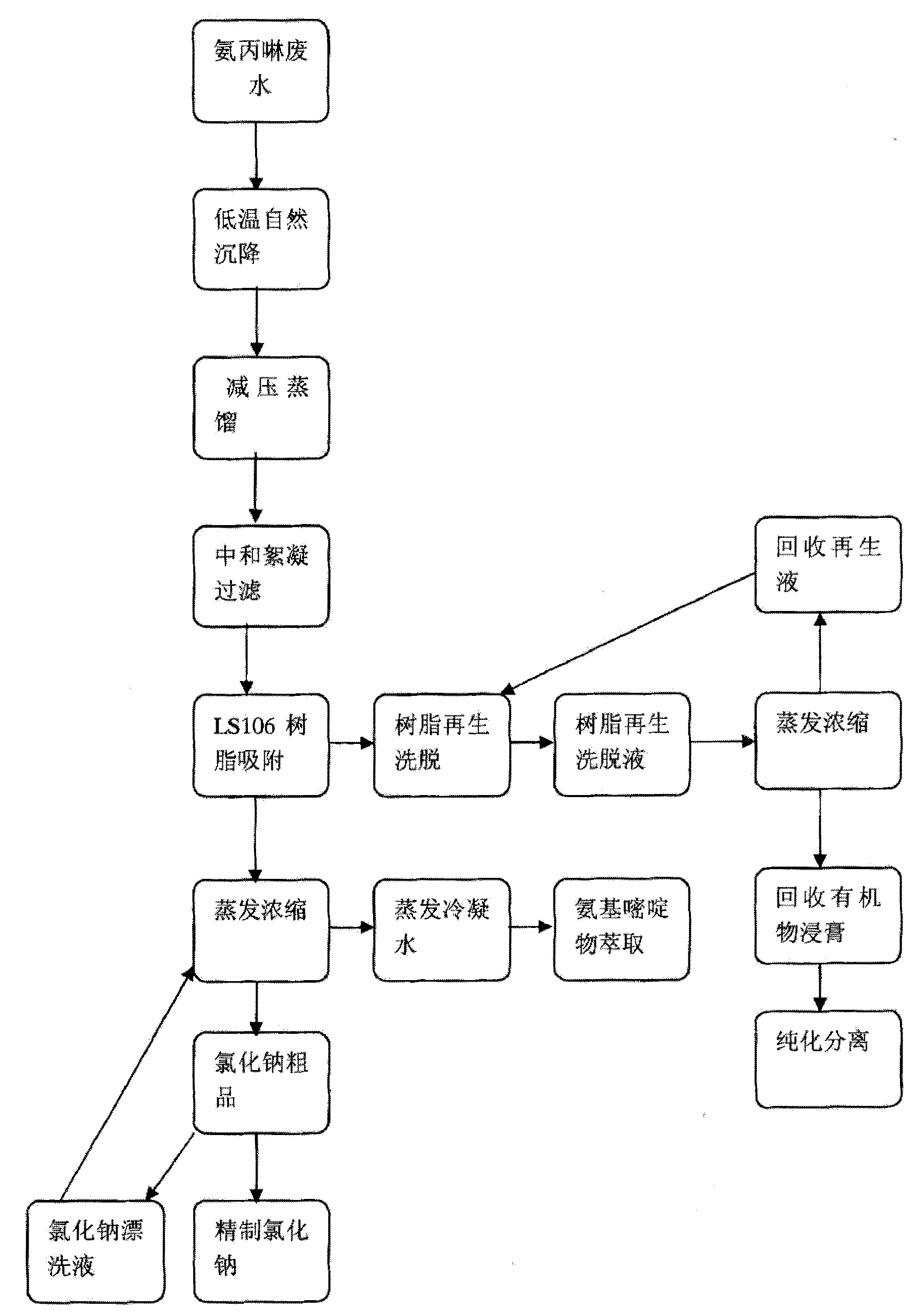

Method used

Image

Examples

Embodiment 1

[0094] Embodiment 1, a kind of comprehensive treatment method of amprolium hydrochloride high-concentration organic process wastewater, this amprolium hydrochloride high-concentration organic process wastewater is the high-concentration organic process produced in the production process of anti-coccidiosis veterinary drug-amprolium hydrochloride Waste water (as shown in table 1); Carry out following steps successively:

[0095] 1), 10,000ml of amprolium hydrochloride high-concentration organic process wastewater (COD is 110,000mg / l) was cooled to 0°C with ice-salt water, and naturally settled for 12 hours to separate 200ml of organic phase and 9,800ml of water phase.

[0096] The 200ml organic phase was concentrated under reduced pressure at a vacuum of 0.09Mpa and a temperature of 55°C to obtain 60g of amprolium hydrochloride intermediate 4-amino-(5-methoxymethyl)-2-propylpyrimidine and chloroform 160ml.

[0097] Therefore, in actual application, the organic phase is directl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap