Method for producing cement

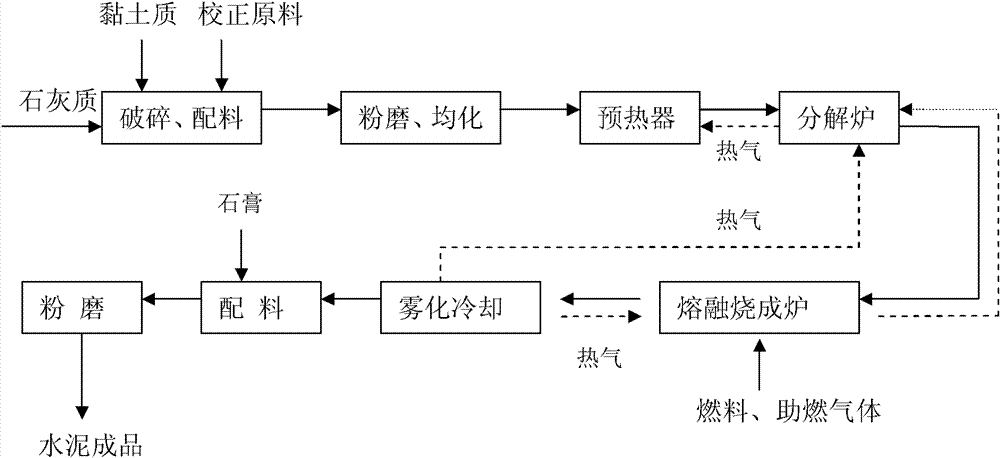

A technology for cement and cement raw meal, applied in clinker production, cement production and other directions, can solve the problems of large energy consumption, low liquid phase, slow reaction rate, etc., to reduce the amount of flue gas and dust, mass transfer Effect of increased heat rate, reduced requirement for homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] From the limestone mine in Pengzhou, Sichuan, the dry clay and iron slag are crushed by the jaw crusher into 10-30mm granular materials and transported into the raw material silo, and weighed as 80% limestone, 15% clay, and 5% iron ore by the belt. The proportion of slag is measured and batched, and the granular materials after batching are conveyed into the vertical pulverizer by the belt conveyor for grinding, and the fineness is controlled at 80um. The sieve residue is less than 2 , adjust the amount of coal sprayed by the coal injection gun placed in the calciner outside the kiln. The temperature in the calciner is 870°C. The decomposed biomass continuously falls into the high-temperature molten pool at 1450-1500°C in the melting and firing furnace. The carbon with a particle size of 15mm added to the top of the melting and firing furnace contacts and burns with the air injected through the top lance at a flow rate of 150m / s to provide the energy required for cement f...

Embodiment 2

[0041]The calcite mine in Mianyang, Sichuan, and the dry loess ore and iron slag in Shifang are crushed by the jaw crusher into 10-30mm granular materials and sent to the raw material silo, and weighed by the belt as 80% calcite, 15% loess, 5 The proportion of iron ore slag is measured and batched. The granular materials after batching are conveyed into the vertical pulverizer for grinding by the belt conveyor, and the fineness is controlled at 80um. The sieve residue is less than 2 , adjust the amount of CO gas injected into the spray gun in the calciner outside the kiln. The temperature in the calciner is 885°C, and the decomposed biomass continuously falls into the high-temperature melting pool at 1390-1440°C in the melting and firing furnace. Carbon with a particle size of 25 mm is added from the top of the melting and firing furnace, and the energy required for cement firing is provided by contacting and burning air with a flow rate of 340 m / s injected through the top lance...

Embodiment 3

[0046] Dolomite ore (chalk), dry shale ore and sulfuric acid slag from Jiangyou, Sichuan, where they are produced, are crushed by a jaw crusher into 10-30mm granular materials and transported into the raw material silo, and weighed as 80% dolomite and 15% page by belt measurement. Rock and 5% sulfuric acid slag are used for metering and batching, and the granular materials after batching are conveyed into the vertical grinding mill for grinding by the belt conveyor, and the fineness is controlled at 80um. The sieve residue is less than 2 , adjust the amount of natural gas injected into the spray gun placed in the calciner outside the kiln. The temperature in the calciner is 880°C, and the decomposed biomass continuously falls into the high-temperature molten pool at 1600-1643°C in the melting and firing furnace. Carbon with a particle size of 50mm is added from the top of the melting and firing furnace, and the energy required for cement firing is provided by contacting and burn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com