Magnetic nanoparticles and flowing preparation method and system thereof

A technology for magnetic nanoparticles and preparation systems, applied in the field of magnetic nanoparticles and their flow preparation, can solve problems such as changes, unpredictable particle size and particle size distribution, achieve high crystallinity, optimize stability and repeatability, and improve transmission. The effect of mass heat transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

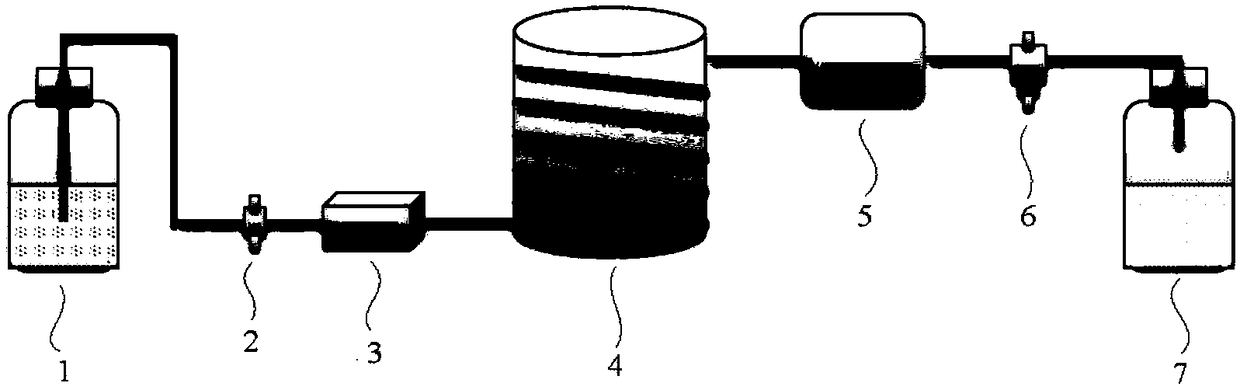

[0051] Example 1 - Flow Preparation System

[0052] refer to figure 1 As shown, the flow preparation system of this embodiment includes a controller and sequentially arranged sampling channels, reactors, coolers, back pressure valves, and sample receiving containers (sample bottles); there is one sampling channel, and the sampling channel There is a sampling valve and a sampling pump on the top, and the reactor includes a heating unit, a temperature feedback unit and a pressure feedback unit;

[0053] The controller controls the work of the sampling valve and the sampling pump on the sampling channel to control the time and flow rate of the fluid in the sampling channel flowing to the reactor;

[0054] The temperature feedback unit detects the temperature in the reactor and transmits it to the controller, and the controller controls the operation of the heating unit according to the received temperature signal to control the reaction temperature in the reactor;

[0055] The ...

Embodiment 2

[0057] Example 2 - Flow Preparation System

[0058] refer to Figure 6 As shown, in the flow preparation system of this embodiment, the number of sampling channels is multiple, and each sampling channel is provided with a sampling valve and a sampling pump respectively. A mixer is also connected to mix the reagents flowing out from each sampling channel. The mixer can be an existing T-type, Y-type or static mixer, which is used to mix various raw materials to form a mixed reaction solution, which is then passed into the reactor for reaction.

[0059] The settings of the controller, reactor, cooler, back pressure valve and sample receiving container in this embodiment are the same as those in Embodiment 1.

Embodiment 3

[0060] Example 3 - Flow Preparation Method

[0061] The flow preparation method of the magnetic nanoparticles of the present embodiment comprises the steps of:

[0062] S1, dissolving the organometallic compound or metal salt compound precursor and small molecules with alkyl chains in a solvent to form a reaction solution;

[0063] S2, passing the reaction solution into a flow preparation system, the flow preparation system includes a flow rate controllable sampling channel, a temperature and pressure controllable reactor, a cooling device and a sample receiving container, the sampling channel, the reactor , the cooling device and the sample receiving container are connected in sequence;

[0064] Control the fluid flow rate in the sampling channel, and pass the reaction solution into the reactor through the sampling channel;

[0065] Control the temperature and pressure in the reactor so that the reaction solution is in a supercritical state in the reactor to react to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com