Solid fuel manufacturing device using a mixture of marine debris and combustible waste as raw material

A technology for solid fuels and manufacturing devices, applied in solid fuels, waste fuels, biofuels, etc., can solve the problems of large energy consumption, large time and manpower consumption, etc., and achieve high-quality economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

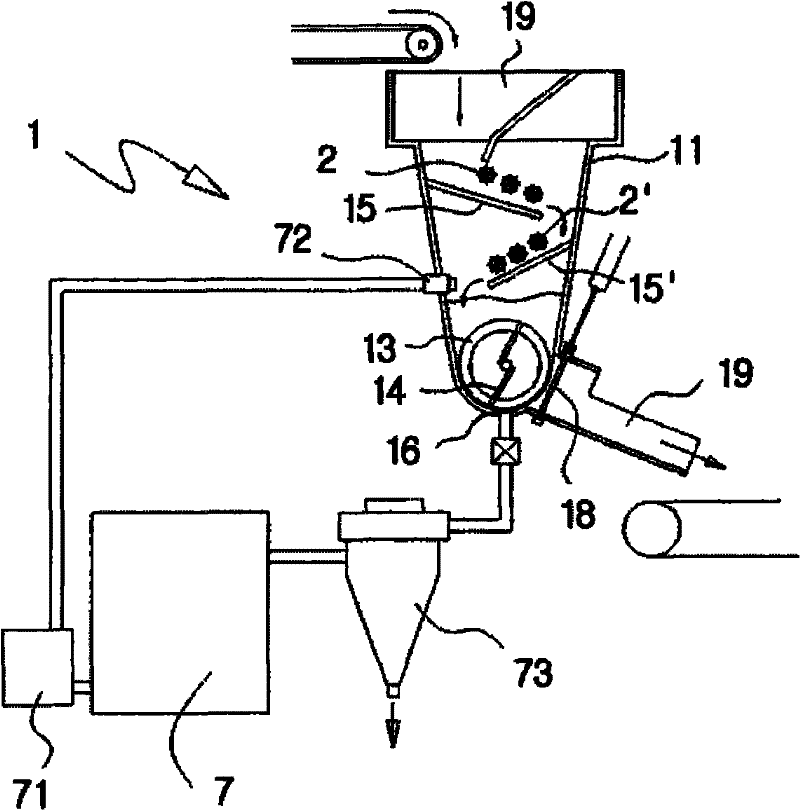

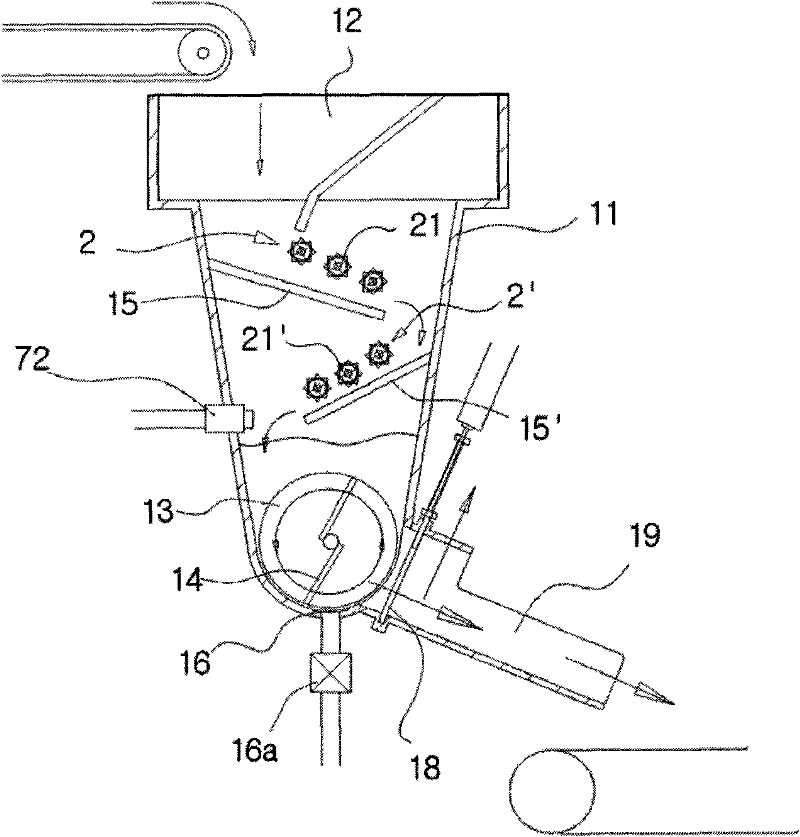

[0050] The purpose of the present invention is to provide a kind of mixed raw material manufacturing by mixing the collected marine wastes after desalination, dehydration, and compression, and then mixing the desalinated, dehydrated and compressed marine wastes with combustible wastes. Manufacturing plant for solid fuel.

[0051] In particular, an object of the present invention is to reduce the volume of collected marine debris by desalinating, dewatering, and compressing the collected marine debris through a series of processes, thereby saving processing costs for transportation and storage of marine debris. At the same time, it is mixed with combustible waste and extruded to make solid fuel more efficiently and economically.

[0052] The manufacture of the solid fuel according to the present invention includes the following steps: after removing attachments such as metals, the marine wastes classified only by synthetic resins are subjected to desalination and dehydration; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com