Self-fixed support member and truss using the self-fixed support member

A technology for supporting components and trusses, which is applied in the field of self-fixing supporting components and trusses using the self-fixing supporting components, can solve the problems of construction and cross-section weakening, labor and time-consuming, and large amount of screws, etc., and achieves convenient processing and transportation, Improve assembly efficiency and reduce the number of screws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

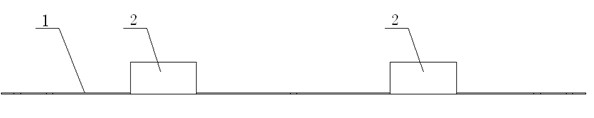

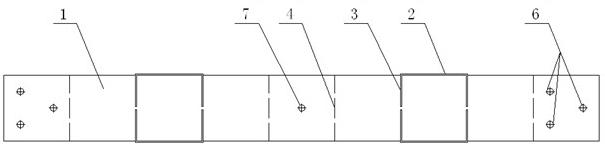

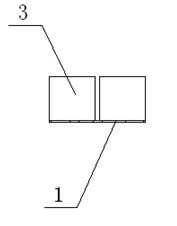

[0033] figure 1 is a front view of a self-fastening support member for a second chord, figure 2 is a top view of a self-fastening support member for a second chord, image 3 It is a left view of a self-fastening support member suitable for two chords; as shown in the figure, the self-fastening support member of this embodiment is suitable for fastening two chords, which includes a strip plate 1, and the strip-shaped Two partitions 2 are vertically arranged on one side of the board 1, and the partitions 2 are distributed at intervals along the length direction of the strip 1, and the strip 1 can be folded toward the side provided with the partition 2 (along the crease line). 4) After connecting into a closed structure, the closed structure formed after folding is as follows Figure 4 shown.

[0034] In this embodiment, the partition 2 is arranged parallel to the length direction of the strip plate 1; of course, the partition can also be perpendicular to the length direction...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 lies in the number of partitions 2 , the self-fastening support member of this embodiment is suitable for fastening four chords, and a four-chord truss is obtained by assembling.

[0045] In the present invention, the chord is not limited to the chord with a square cross-section as shown in the figure, and the chord can also be a steel pipe processed from cold-formed steel; Made of high-strength metal plates; the number of partitions is one or more, depending on the number of chords to be fastened; when assembling the truss, at least one self-fastening support member is used to connect the fastening chords, according to the number of chords Depending on the length or actual use requirements, multiple self-fastening support members can be arranged along the length direction of the chord.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com