Rotary steerable tool and its biasing mechanism and control method for the biasing mechanism

A rotary steering and tool technology, applied in the automatic control system of drilling, directional drilling, earth-moving drilling, etc., can solve problems such as the instability of the drilling platform, the pressure drop of the drilling fluid, and the ability of the drilling fluid to purify the wellbore, etc. The effect of accurate guidance and stable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

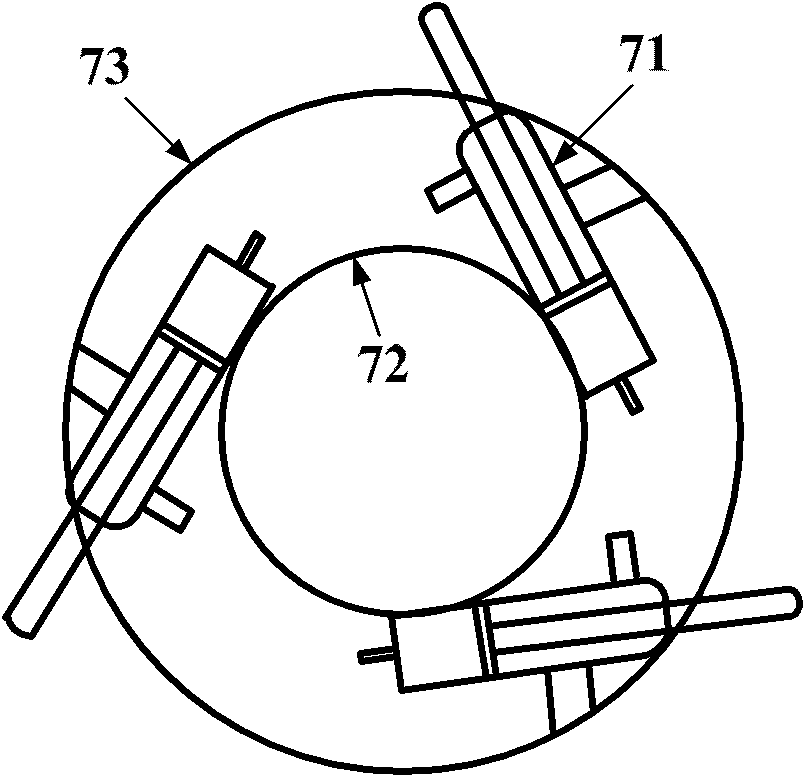

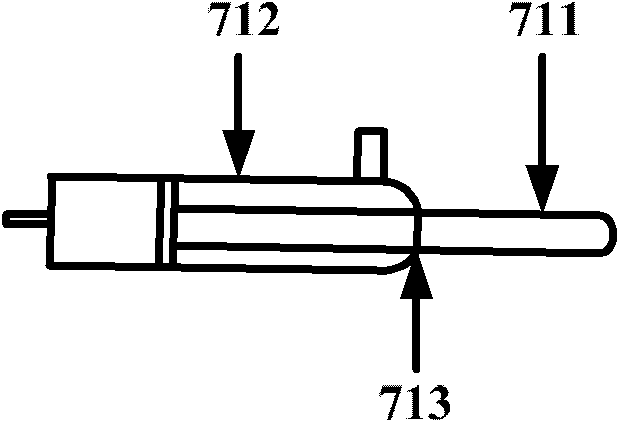

[0038] This embodiment firstly provides a biasing mechanism for a rotary guiding tool. Wherein, a plurality of hydraulic support implements of the biasing mechanism are installed on the outer cylinder of the biasing mechanism. Hydraulic support equipment mainly includes hydraulic support ribs, asymmetric hydraulic cylinders, displacement sensors, etc. The hydraulic support tool pushes the support rib out of the outer cylinder through the pressure difference between the left and right chambers of the asymmetric hydraulic cylinder and reaches the well wall. During the operation, the displacement sensor detects the displacement of the support rib in real time. On the shaft wall, the reaction force of the shaft wall to the supporting rib is used as the disturbance of the hydraulic position control system, so as to meet the given value of the control requirement.

[0039] Figure 1a It is a cross-sectional schematic diagram of a biasing mechanism according to an embodiment of the ...

Embodiment 2

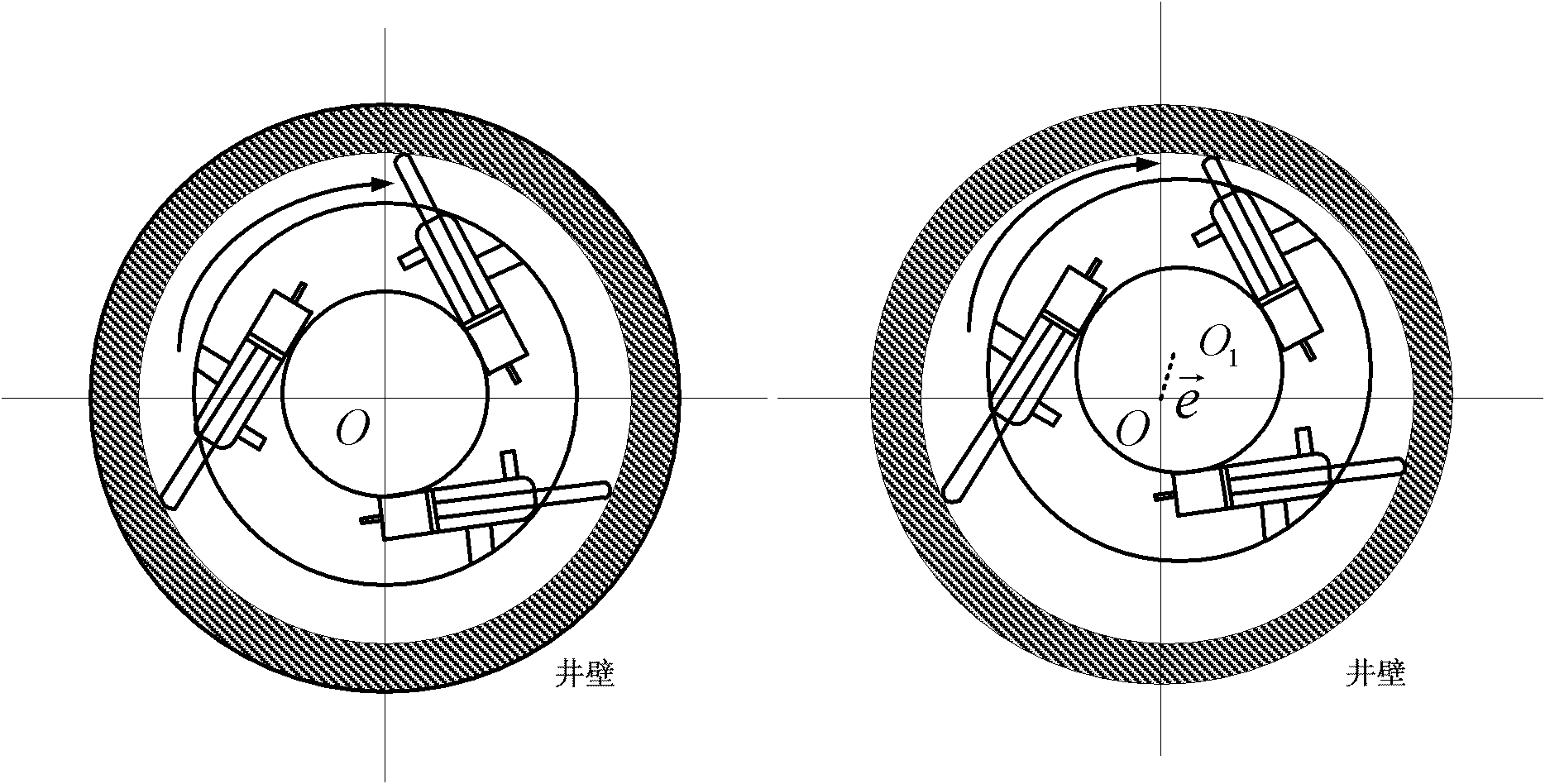

[0056]An embodiment of the present invention provides a rotary guiding tool including the biasing mechanism described in Embodiment 1. Figure 7 It is a structural schematic diagram of a rotary steerable tool according to an embodiment of the present invention. Figure 8 It is a schematic diagram of the offset mode of the rotary steerable tool according to the embodiment of the present invention. Such as Figure 8 As shown, the working mode of the offset mechanism of the rotary steering tool in this embodiment is a push-to-drill type, and the outer cylinder of the offset mechanism is rotating; the rotary steering tool in this embodiment adopts the "displacement working mode", and finally uses The drill bit produces an offset angle relative to the borehole axis to achieve steering.

[0057] Such as Figure 7 As shown, the rotary steering tool of this embodiment at least includes: the biasing mechanism 7 described in Embodiment 1 and the hydraulic control system (included in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com