Distributed direct-mixing heat supply system

A heating system, distributed technology, applied in heating systems, hot water central heating systems, household heating, etc., can solve the problem that the design scale cannot meet the needs of development, reduce the transmission efficiency of the pipeline network, and affect the full utilization of heat, etc. problems, to achieve the effect of improving full utilization, improving transmission efficiency, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

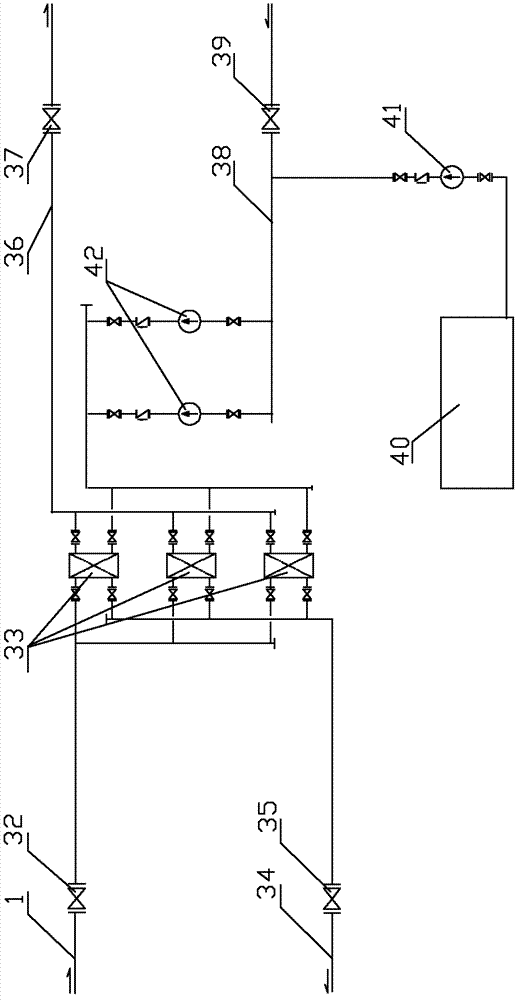

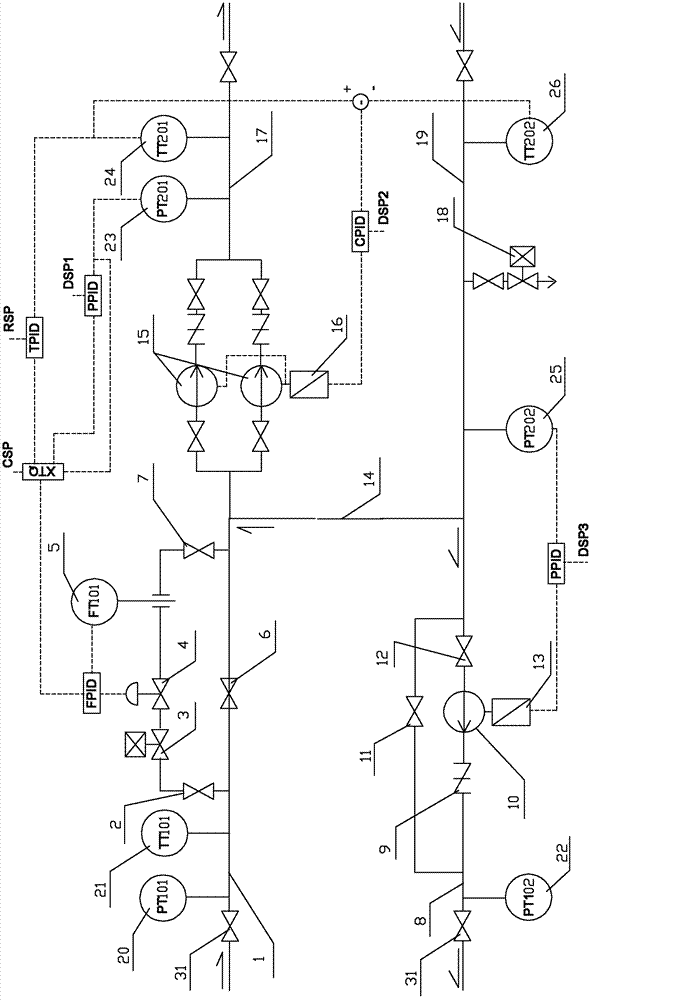

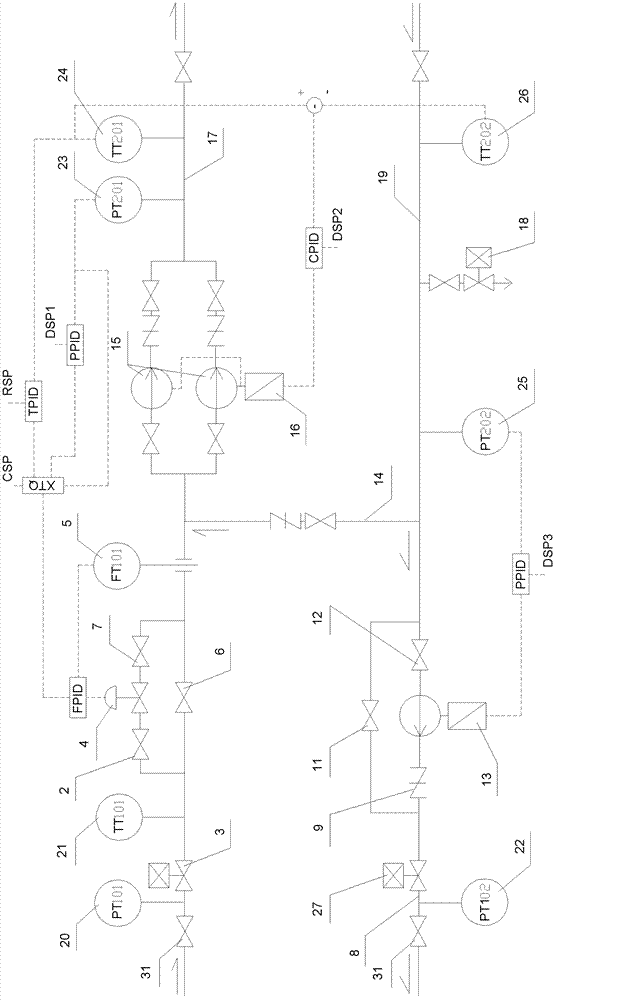

[0034] A distributed direct mixing heating system and its embodiments of the present invention will be described in detail below with reference to the accompanying drawings. All control instruments in the system are purchased from the market; a heat exchange station is equipped with a main console, and each control instrument completes its control tasks in the main console. The English symbols in the figure are numbers commonly used in this industry, and are symbols representing control functions. After reading the control instrument manual, those skilled in the art can understand its function and use, and can implement it.

[0035] attached figure 1 It is a schematic diagram of the heat supply process for heat exchange with a traditional format heat exchanger. It belongs to the existing technology; it describes that the original heating network system in the heating area of the traditional thermal power plant is a high-temperature water heating system of central heating "c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com