Electronic image pickup device

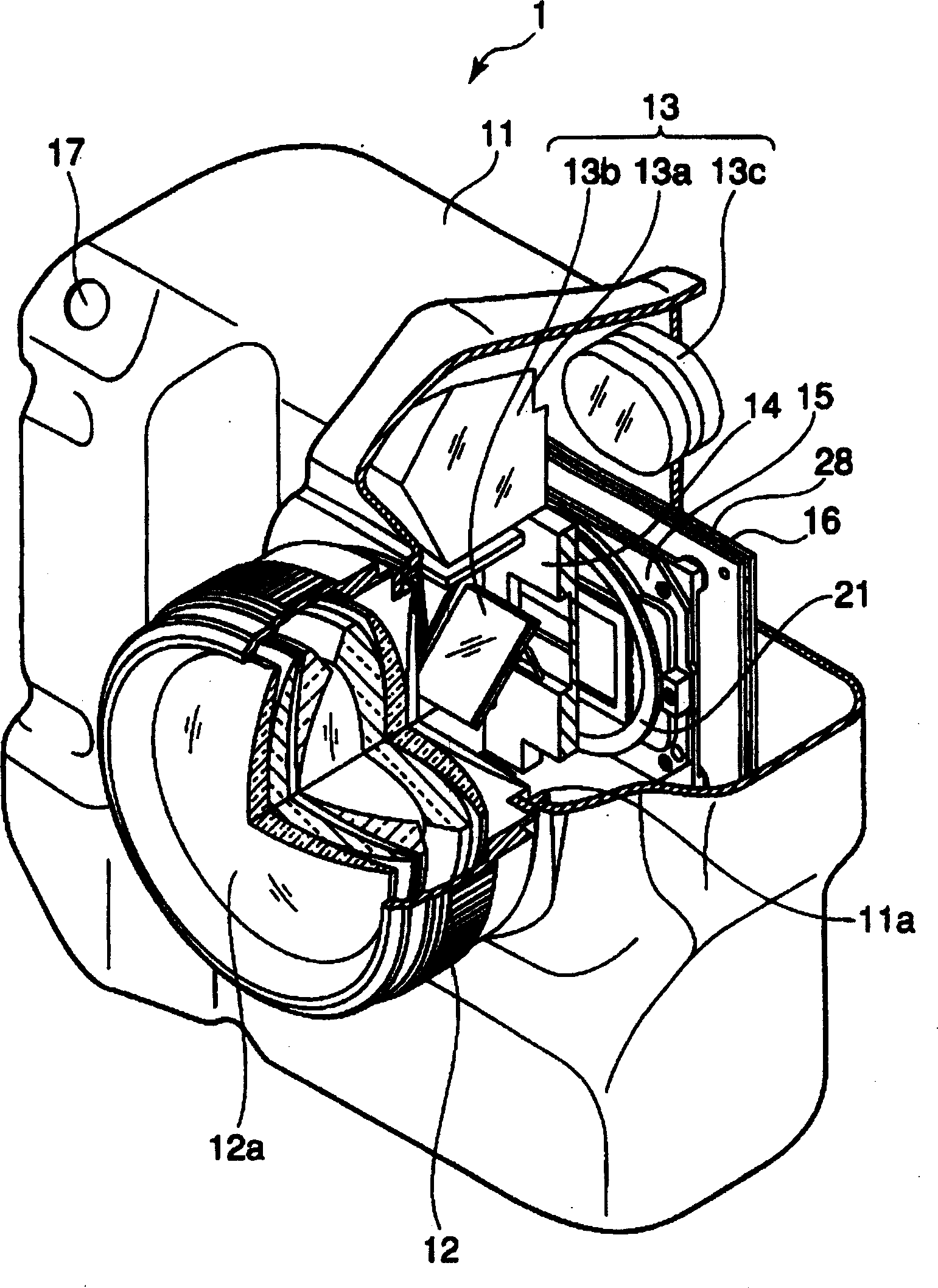

A camera device, electronic technology, applied in static cameras, TVs, color TVs, etc., can solve problems such as the problem of undisclosed dust adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

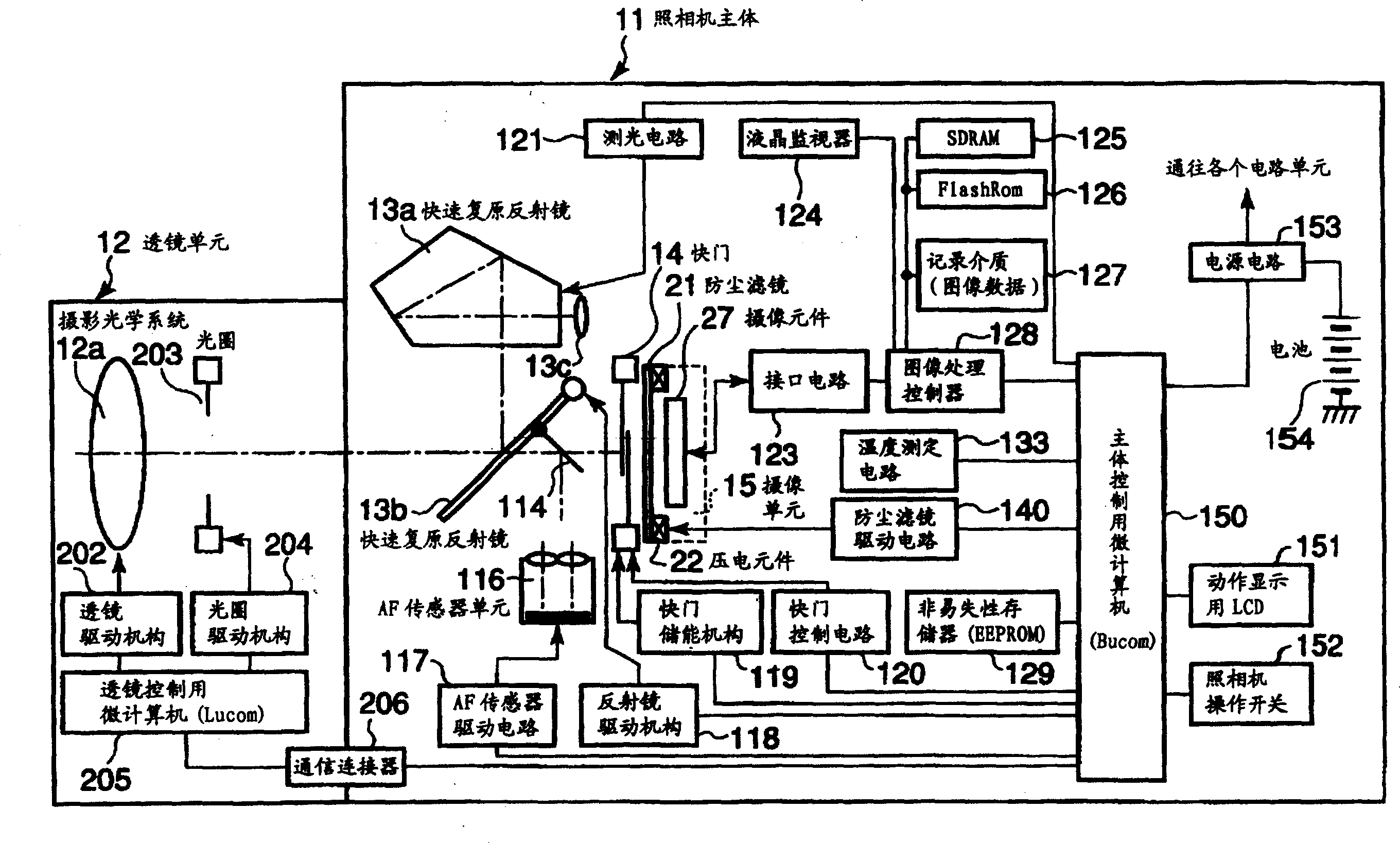

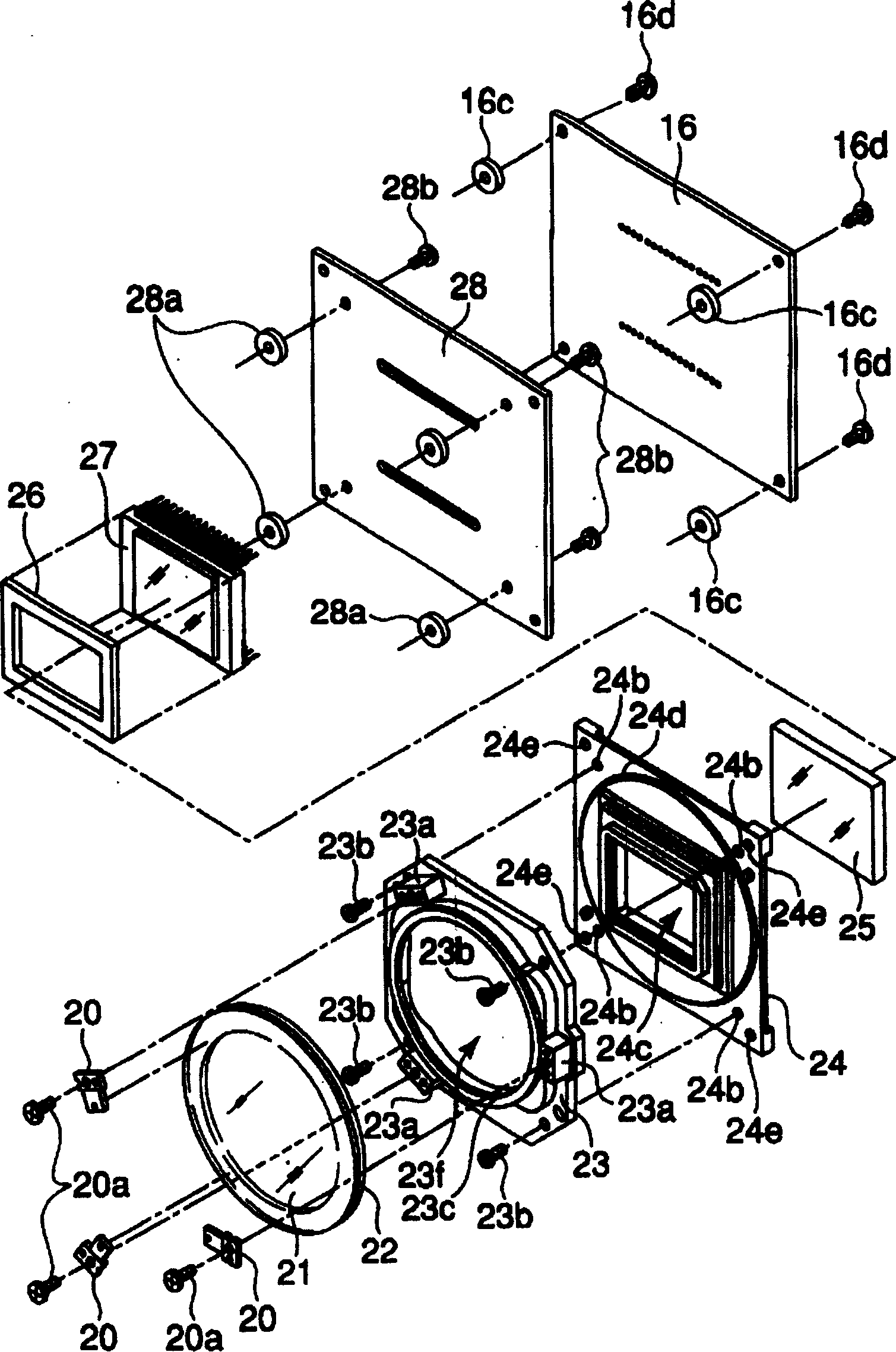

no. 1 Embodiment approach

[0182] Figure 13 It is a flowchart for explaining the operation of Bucom 150 in the camera system according to the first embodiment of the present invention.

[0183] If the power switch of the camera is turned on (ON), the Bucom150 starts to work. In step S100, processing for starting the camera system is performed. The power supply circuit 153 is controlled to supply power to each circuit unit constituting the camera system. In addition, the initial setting of each circuit is performed.

[0184] Step S101 is an operation step for detecting the state of the lens unit 12 through a communication operation with Lucom 205 , and is executed periodically. If it is detected in step S102 that the lens unit 12 has been attached to the camera body 11, the process proceeds from step S102 to step S103. In step S103, the two piezoelectric elements 22a and 22b provided on the dustproof filter 21 are driven in phase at the resonance frequency (f0) for a predetermined time (T0). In ord...

no. 2 Embodiment approach

[0210] Figure 17 It is a flowchart for explaining the operation of Bucom 150 in the camera system according to the second embodiment of the present invention. The second embodiment is characterized in that the subroutine "imaging operation" described in the first embodiment ( Figure 13 In step S119), the dustproof filter 21 is driven intermittently. Other steps are the same as in the first embodiment.

[0211] First, in step S400, the status of the dust-proof permission flag is detected. If the dustproof permission flag is "1", go to step S401 to start the vibrating action of the dustproof filter 21. In step S401 , a predetermined drive signal is applied to the piezoelectric elements 22 a , 22 b that vibrate the dustproof filter 21 . After that, go to step S402.

[0212] On the other hand, if the dustproof permission flag is "0" at step S400, then immediately go to step S402. In step S402, the image processing controller 128 is instructed to start the imaging operation...

no. 3 Embodiment approach

[0217] Figure 18 It is a flowchart for explaining the operation of Bucom 150 in the camera system according to the third embodiment of the present invention. The third embodiment is characterized in that the subroutine "imaging operation" described in the first embodiment ( Figure 13 In step S119), traveling waves are used to drive the dustproof filter 21. Other steps are the same as in the first embodiment.

[0218] First, in step S300, the status of the dustproof permission flag is determined. If the flag is "1", go to step S301 to start the vibrating action of the dustproof filter 21 . In step S301, drive signals having a frequency (fs) and a phase of 90° are applied to the two piezoelectric elements 22a and 22b. Through this action, such as Figure 10 As shown, traveling waves are generated in the dust filter 21 . By selecting a driving method with a small amount of deformation of the dust filter 21 , it is possible to suppress an increase in aberration caused by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com