Apparatus and method for sterilizing container closures

An equipment and capping technology, which can be used in the direction of tightly capping containers with caps, sanitary equipment for toilets, bottle/container caps, etc. higher question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

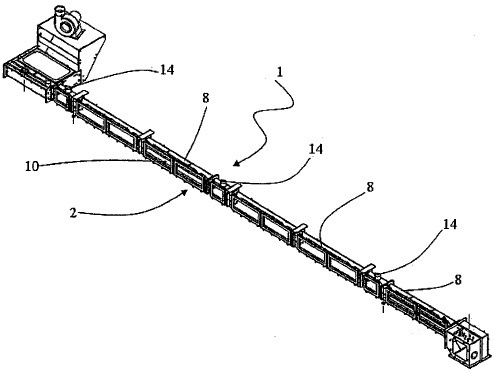

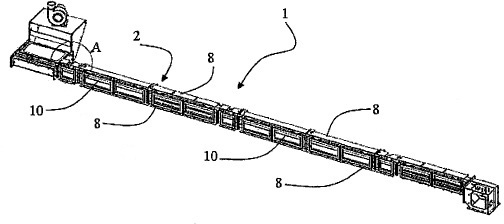

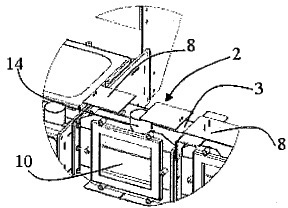

[0043] Referring to the accompanying drawings, numeral 1 designates equipment for sterilizing container closures, such as caps or stoppers used to seal containers, installed on containers at the end of the filling process.

[0044] Said device 1 comprises a duct 2 having a passage through which the closures pass. This duct 2 has at least one wall 3; in particular, said duct 2 has a side wall 3 which surrounds said passage through which the cover passes.

[0045] In the illustrated embodiment, said duct 2 has a rectangular section; correspondingly, said wall 3 has four faces, each of which is approximately planar.

[0046] In addition, the pipes 2 are preferably arranged longitudinally. Of course, the duct 2 does not have to be arranged in this way; in fact, said duct 2 can have a different shape, for example a duct with walls 3 that are circular in cross-section and follow a curvilinear path.

[0047] A conveyor belt (not shown) is provided in the duct 2 for transferring the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com