A collimating mechanism for a convexity meter

A technology of convexity meter and collimation, applied in the field of nuclear technology application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

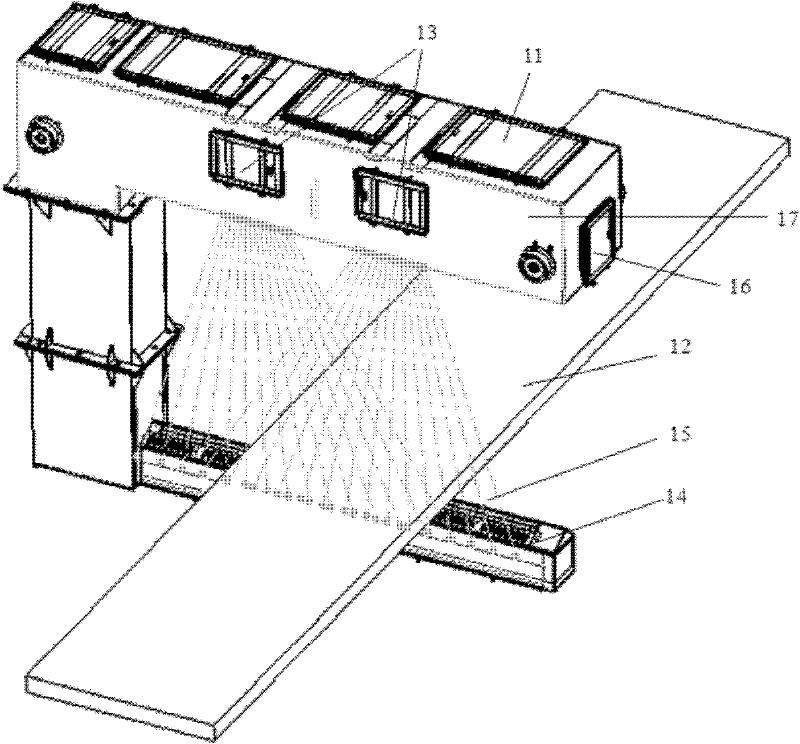

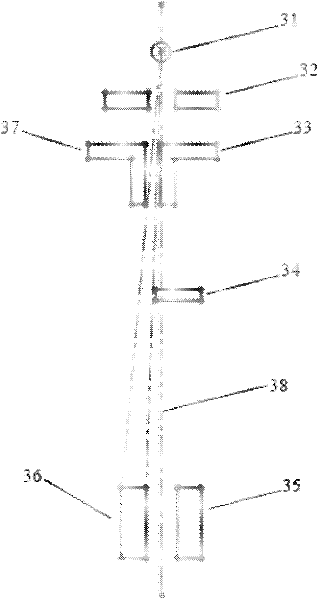

[0023] The convexity meter targeted by the present invention uses two sets of radiation source-detector array combinations, such as figure 1 As shown, the direction perpendicular to the upper arm end surface 16 of the C-shaped frame is the X direction, and the direction perpendicular to the side surface 17 of the C-shaped frame is the Y direction. In the X direction as image 3 As shown in the figure, two X-ray machines are spaced apart in the same linear direction in the X direction, the detector arrays are arranged along the X direction, and the two rows of detector arrays 35 and 36 are parallel.

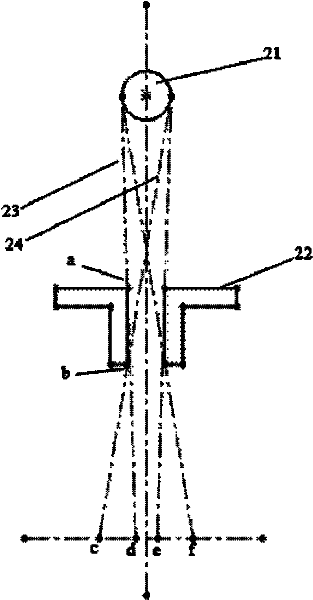

[0024] The X-ray beam emitted by the X-ray machine is an elliptical cone beam, the long axis is along the X direction, and the short axis is along the Y direction, and the angle is 90°×30°. Also in the X and Y directions, the solid angle of the detector array relative to the X-ray machine is 45°×0.34°, such as image 3 As shown, in the Y direction, the distance between the two rows of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com