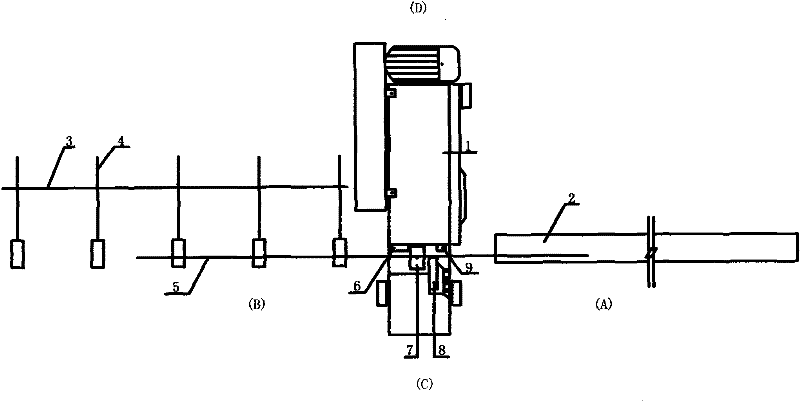

Straight end steel bar cutting machine

A steel bar cutting machine, cutting machine technology, applied in the field of steel bar cutting machine, can solve the problems of high cost, inability to use straight thread threading, hindering the development of steel bar connection technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

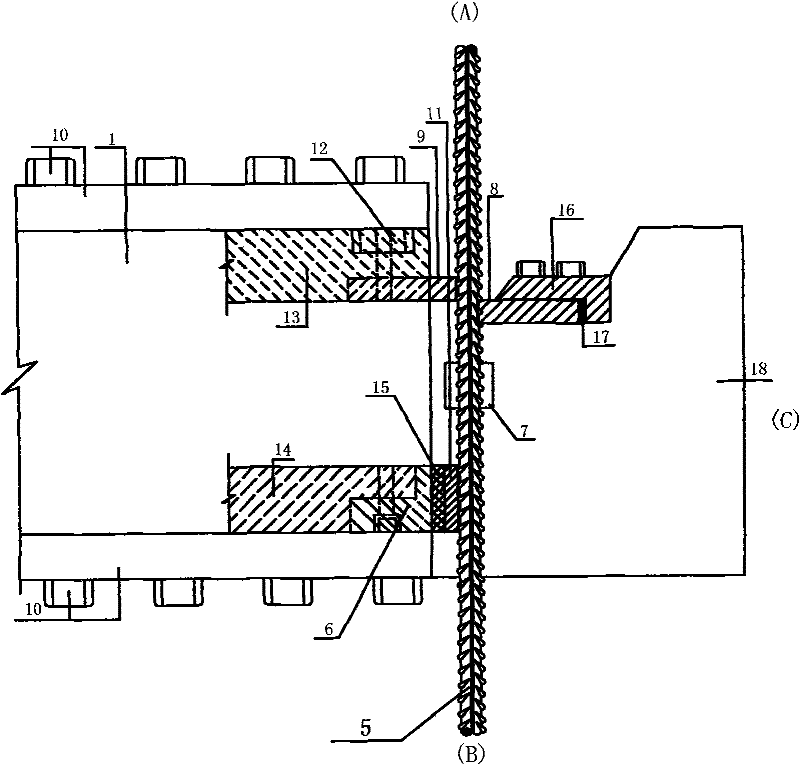

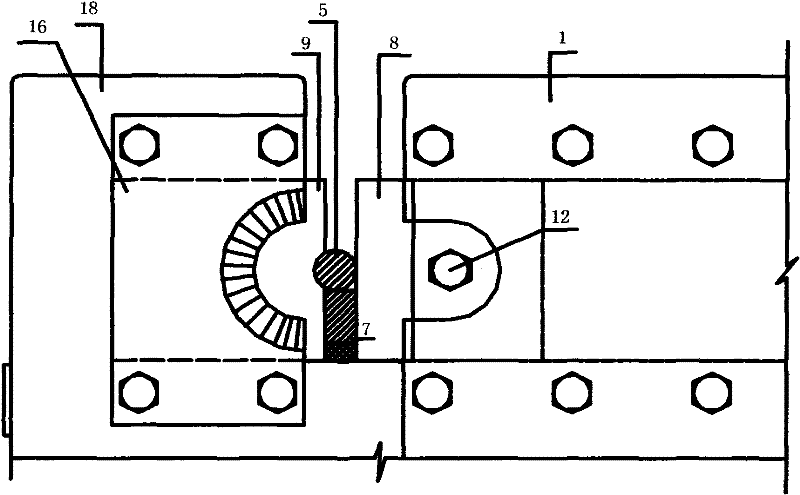

[0024] 1. First, adjust and position the steel plate gasket in the middle of the top pressing block according to the diameter of the steel bar to be cut. (The steel plate gasket is designed to be E-shaped, and an arc-shaped gap is set between the block and the head steel plate to facilitate the removal of the gasket) so that the steel bar and the fixed blade form an included angle of 90 degrees.

[0025] 2. Adjust the height adjustment pad so that the steel bars to be cut are placed at the arc of the blade of the arc-shaped incision cutting machine. If 2 or 3 pieces are cut each time, 2 or 3 arc-shaped incision steel bar cutting machines can be used. The blade makes 2 and 3 steel bars horizontally arranged and integrated into one, and then enters the arc-shaped incision to cut off.

[0026] 3. The continuous cutting operation method can be used for single cutting, and the foot-operated cutting method should be used for cutting 2 or 3 roots at a time.

[0027] 4. Before the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com