Dregs tipping device

The technology of tipping bucket device and muck bucket is applied in the directions of transportation and packaging, heavy-duty pulley, load hanging element, etc. It can solve the problems of low efficiency, hidden danger and high cost, and achieve the effect of high work efficiency, low cost and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

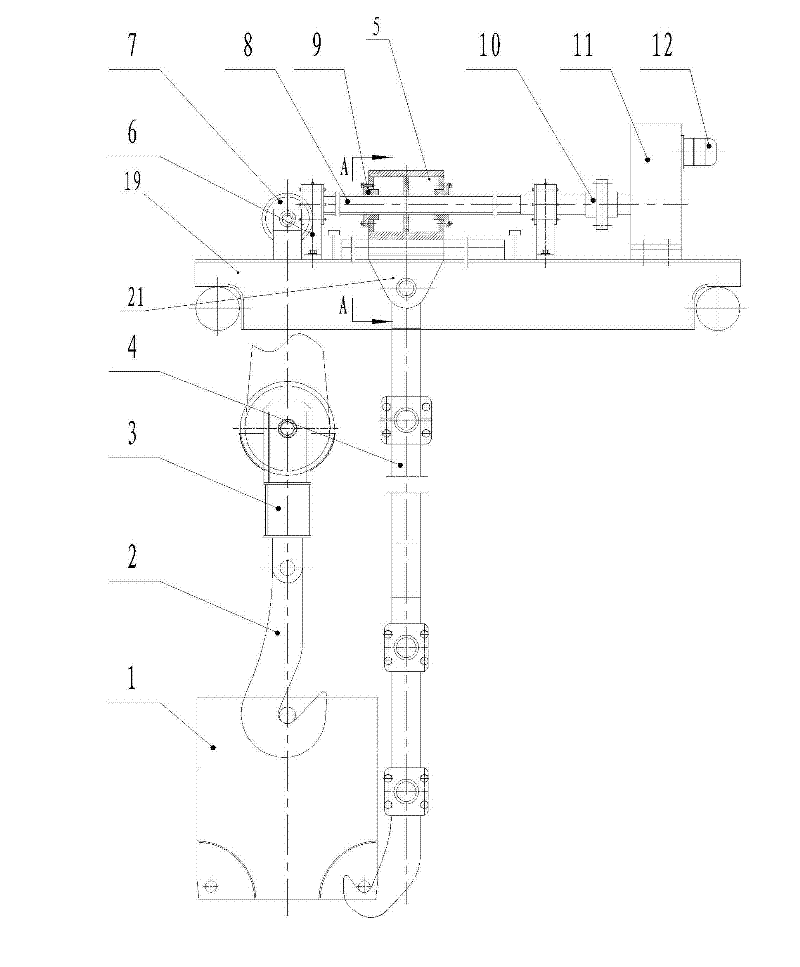

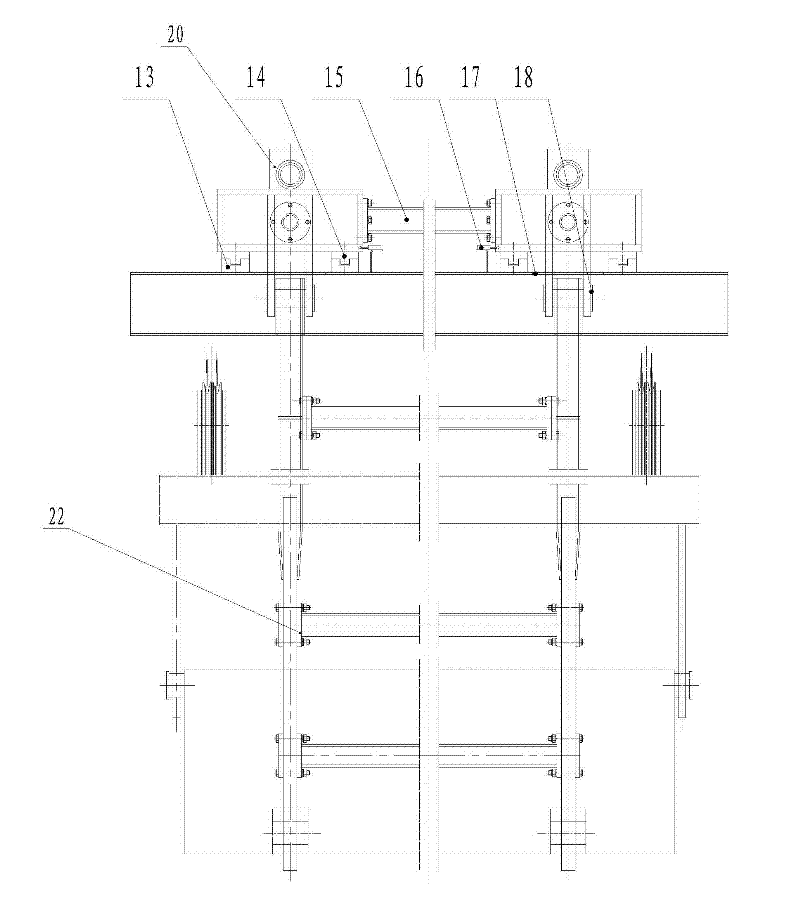

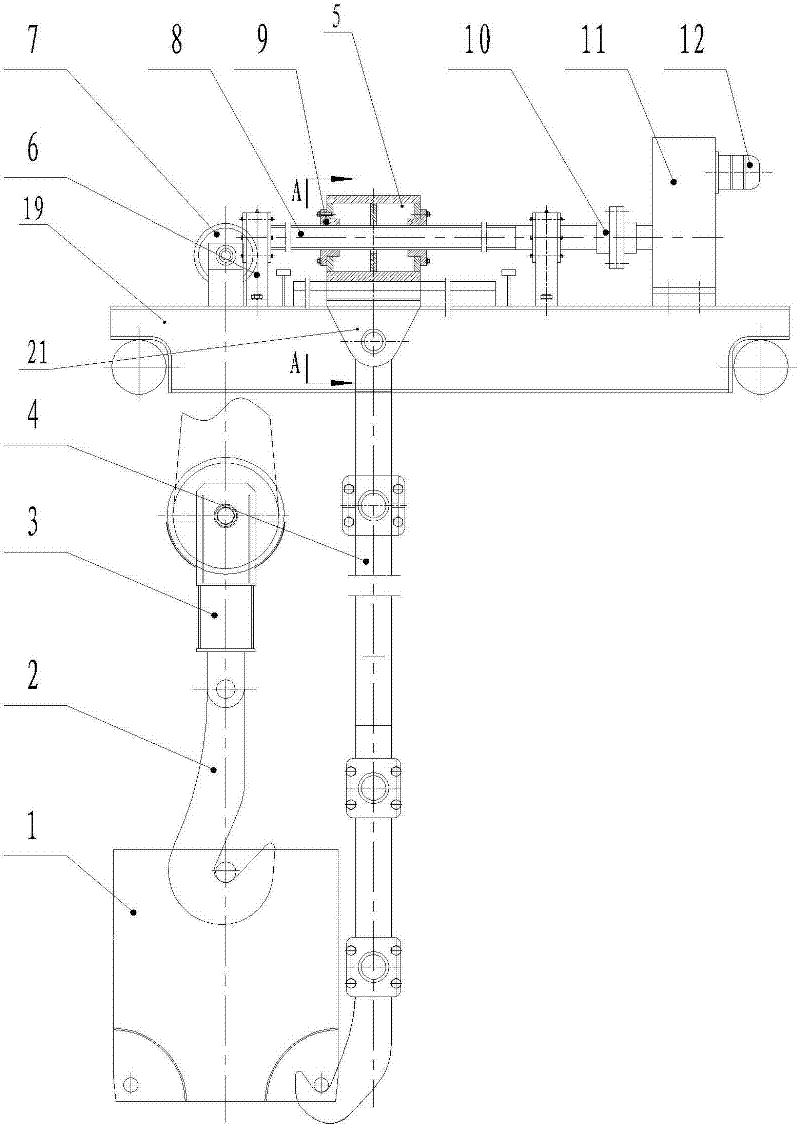

[0020] Such as figure 1 , figure 2 As shown, the present invention includes a muck bucket 1, a trolley 19 and a discharge mechanism 20, and the discharge mechanism 20 mainly includes a tipping bucket hook 4, a sliding seat 5, a bearing seat 6, a lead screw 8, a guide sleeve 9, and a gear coupling 10. Reducer 11, motor 12, fixed guide rail 13, movable guide rail 14, connecting rod 15, travel switch 16, bearing pin 18. The motor 12 installed on the reducer 11 transmits the power to the reducer 11, and after deceleration, the power is transmitted to the lead screw 8 through the gear coupling 10. The lead screw 8 and the guide sleeve 9 installed on the sliding seat 5 are Threaded connection, pushing the sliding seat 5 forward and backward along the fixed guide rail 13, the sliding seat 5 drives the tipping bucket hook 4 on the ear plate at the lower end to advance and retreat at the same time, realizing the automatic loading and unloading of the muck bucket 1; The suspension be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com