Synchronous splitting device for full-section multifunctional channel concrete lining machine

A full-section, lining machine technology, which is applied in artificial waterways, water conservancy projects, construction, etc., can solve the problems of time-consuming, poor consistency of cutting seams, laborious and other problems, and achieve the effect of improving operation efficiency and good dimensional consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

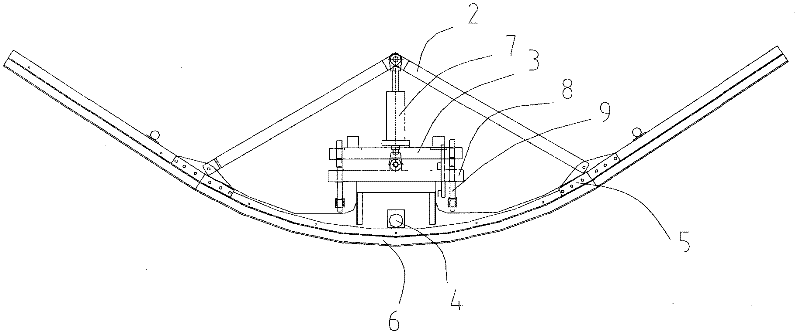

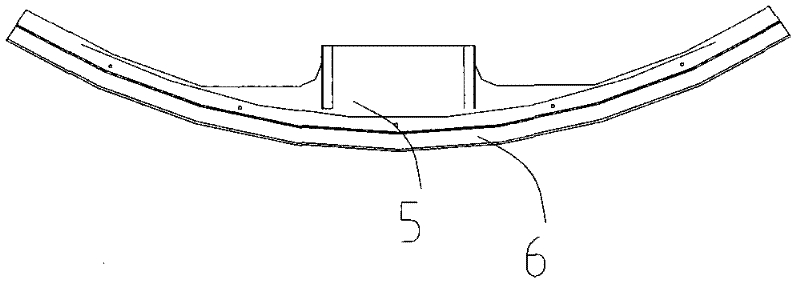

[0014] During the operation process, the full-section multi-functional channel concrete lining machine walks forward at a constant speed driven by the walking system. The lining system performs the concrete lining compaction operation at the same time, and then divides the lining layer, because it is in the process of lining compaction operation. Therefore, it is called synchronous splitting, and the device that realizes synchronous splitting is called synchronous splitting device.

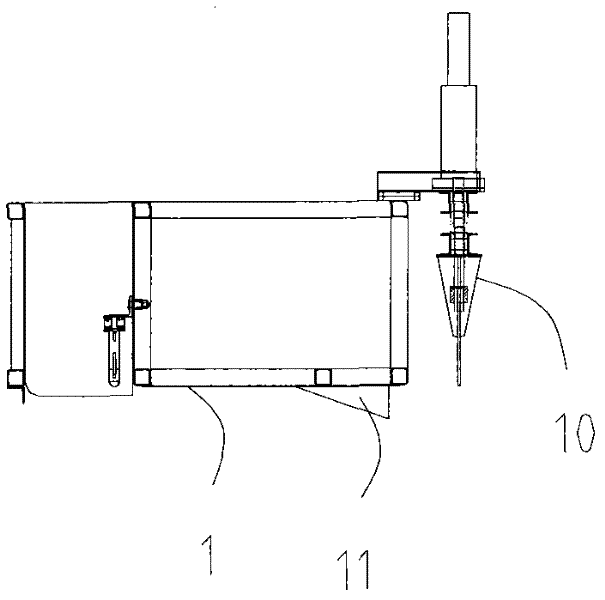

[0015] Such as figure 2 As shown, the synchronous seam forming device includes a full-section transverse seam forming device 10 and a longitudinal seam forming device 11; the full-section transverse seam forming device 10 is fixedly installed behind the working direction of the lining system 1; the longitudinal seam forming device 11 is fixed The cutting knives with high front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com