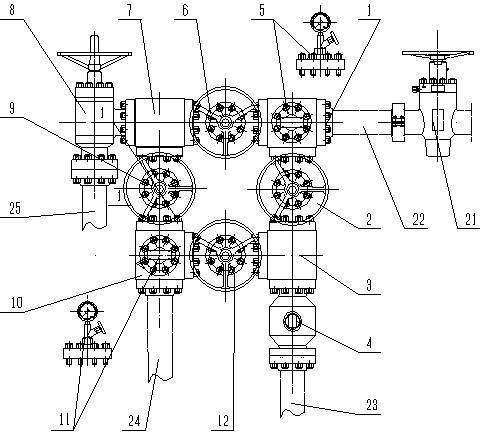

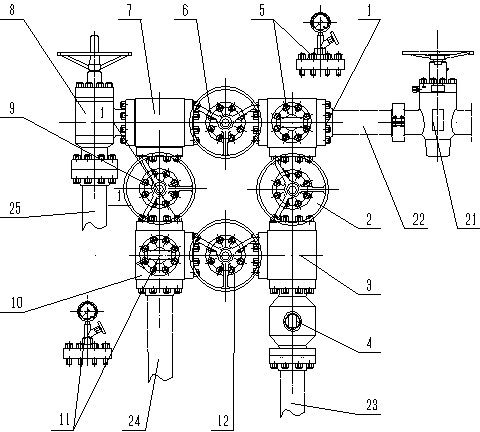

Multifunctional kill and blowout manifold

A multi-functional, well-killing technology, which is applied in the direction of flushing wellbore, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of many connecting parts, cumbersome operation, and leakage of connection points, so as to achieve safe and reliable operation and occupy space The effect of being small and having few connecting parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] The multifunctional kill and blowout manifold of the present invention includes four-way A1, four-way B10, three-way A3, manual throttle valve 8, check valve 4 and four flat valves; two ports of four-way A1 They are respectively connected with plate valve A2 and plate valve D6, and there is a pressure gauge A5 installed on the interface of four-way A1, and the other interface of four-way A1 is spare; the above-mentioned plate valve A2 is also connected with one interface of three-way A3; three-way The other two ports of A3 are respectively connected with the flat valve B12 and check valve 4; the flat valve B12 is also connected with one port of the four-way B10; the other port of the four-way B12 is connected with the flat valve C9, and the four-way B10 There is also a pressure gauge B11 on the interface, and another interface of the four-way B10 for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com